Plate glass surface grinding device and method

A technology of surface grinding and flat glass, which is applied in the direction of machine tools, grinding machines, grinding/polishing equipment suitable for grinding workpiece planes, etc. It can solve the problems of difficult manufacturing of equipment, high substrate cost, and low grinding efficiency, and achieve good performance. Cost-effective, high processing efficiency, good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

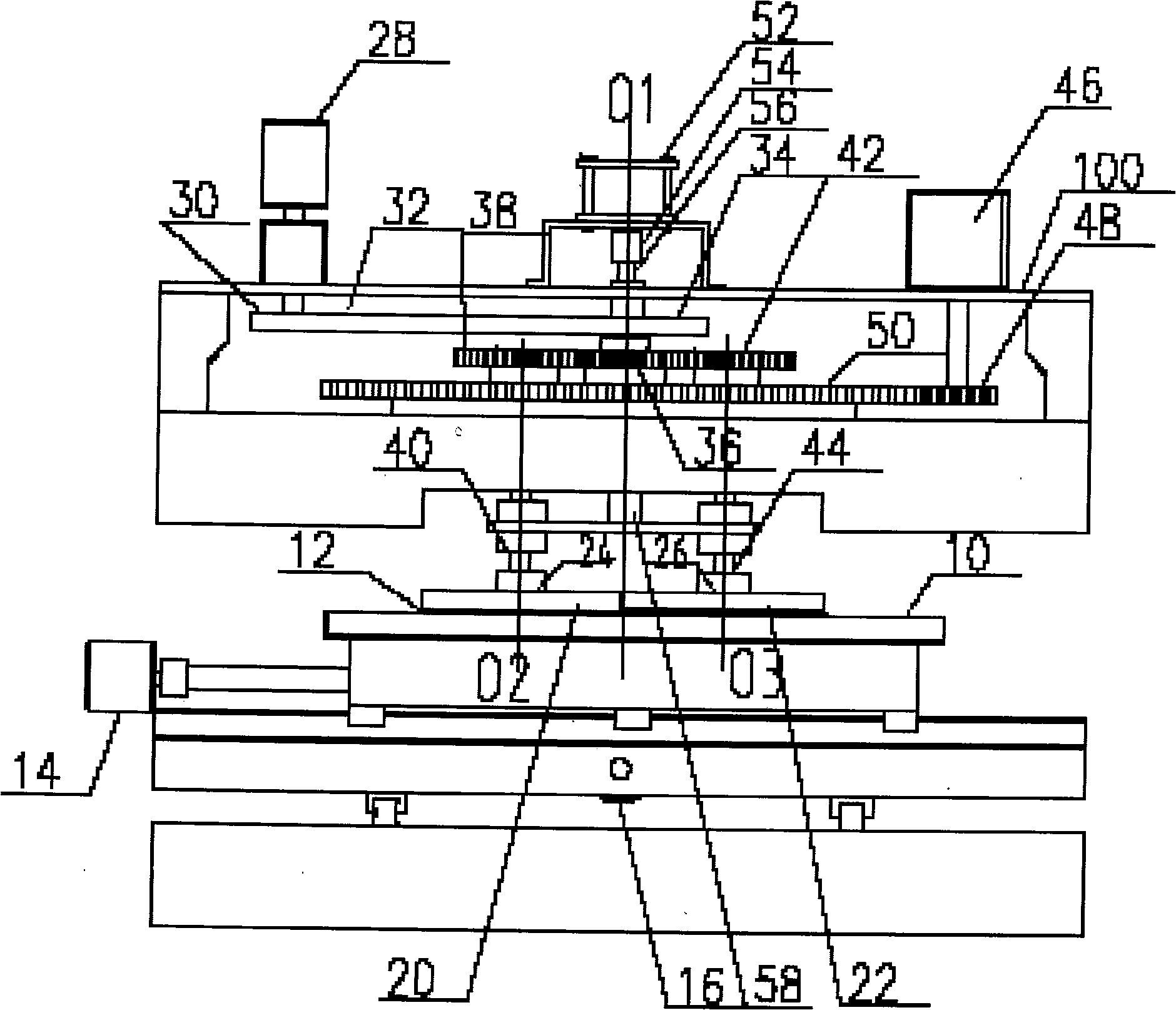

[0027] The following describes in detail in conjunction with the embodiments of the present invention and the accompanying drawings.

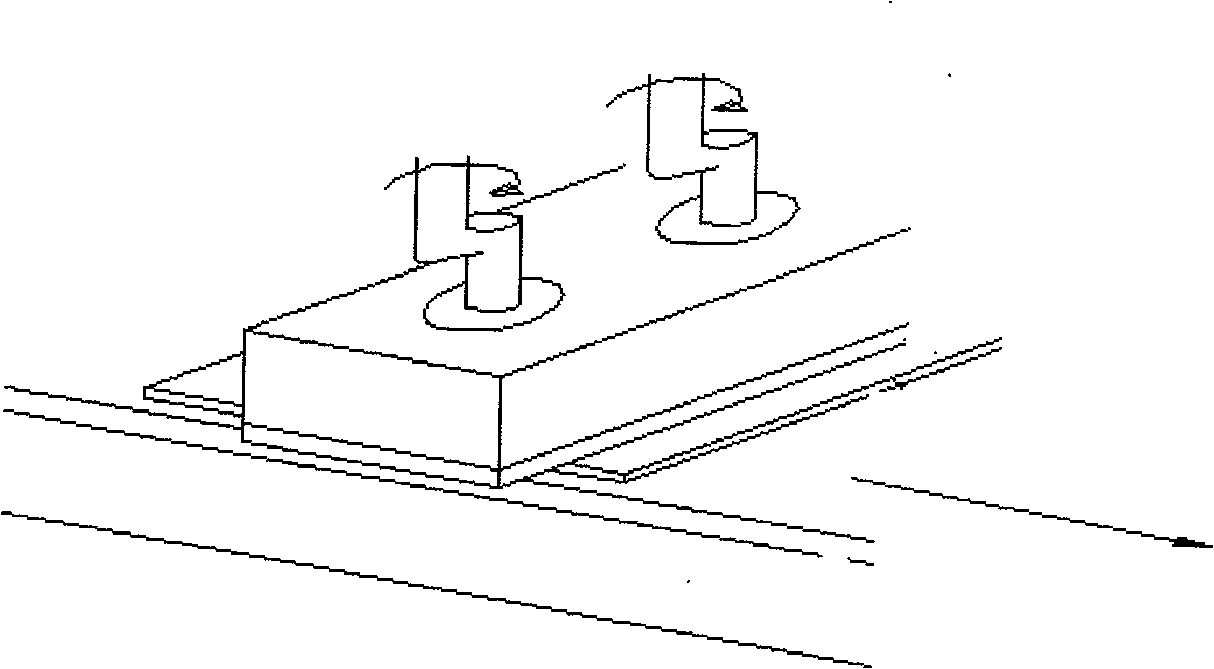

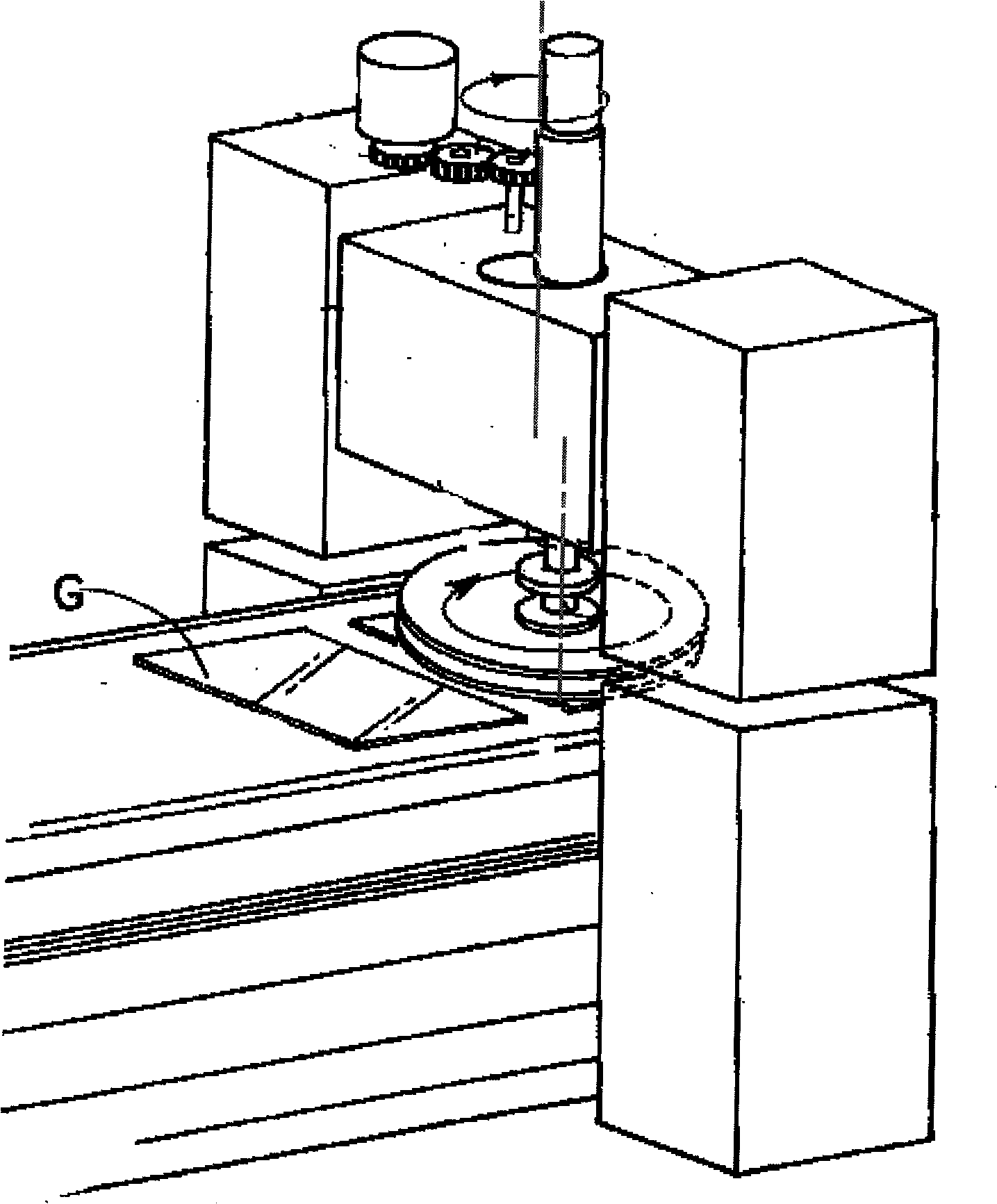

[0028] The device includes a grinding table installed on a guide rail that can move independently in the X and Y directions, an equipment base that carries a moving guide rail, and two or more grinding heads that rotate at a predetermined speed, so that the grinding head can move along a certain track. Rotary gear transmission system, grinding head, revolution drive motor, grinding head lifting cylinder and man-machine interface, etc. The workbench of the grinding machine is made of materials such as marble with small deformation and thicker glass plate that are less affected by the change of ambient temperature. The glass plate for grinding can be placed on this non-metallic workbench with small expansion coefficient. You can paste a PAD block with certain elasticity (such as polyurethane rubber, etc.), which has good air permeability, and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com