Grinding device for grain processing

A grinding device and grain technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of failing to meet customer processing requirements, reducing grain quality, increasing production costs and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

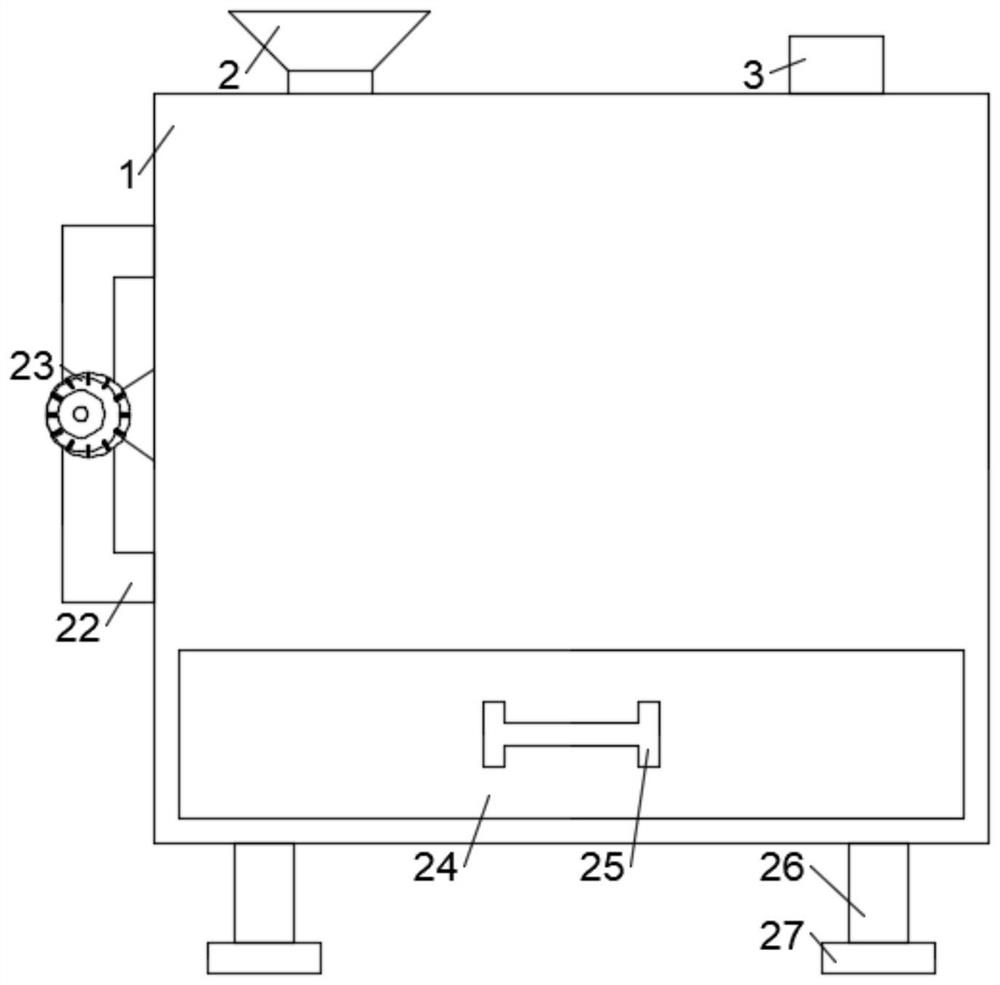

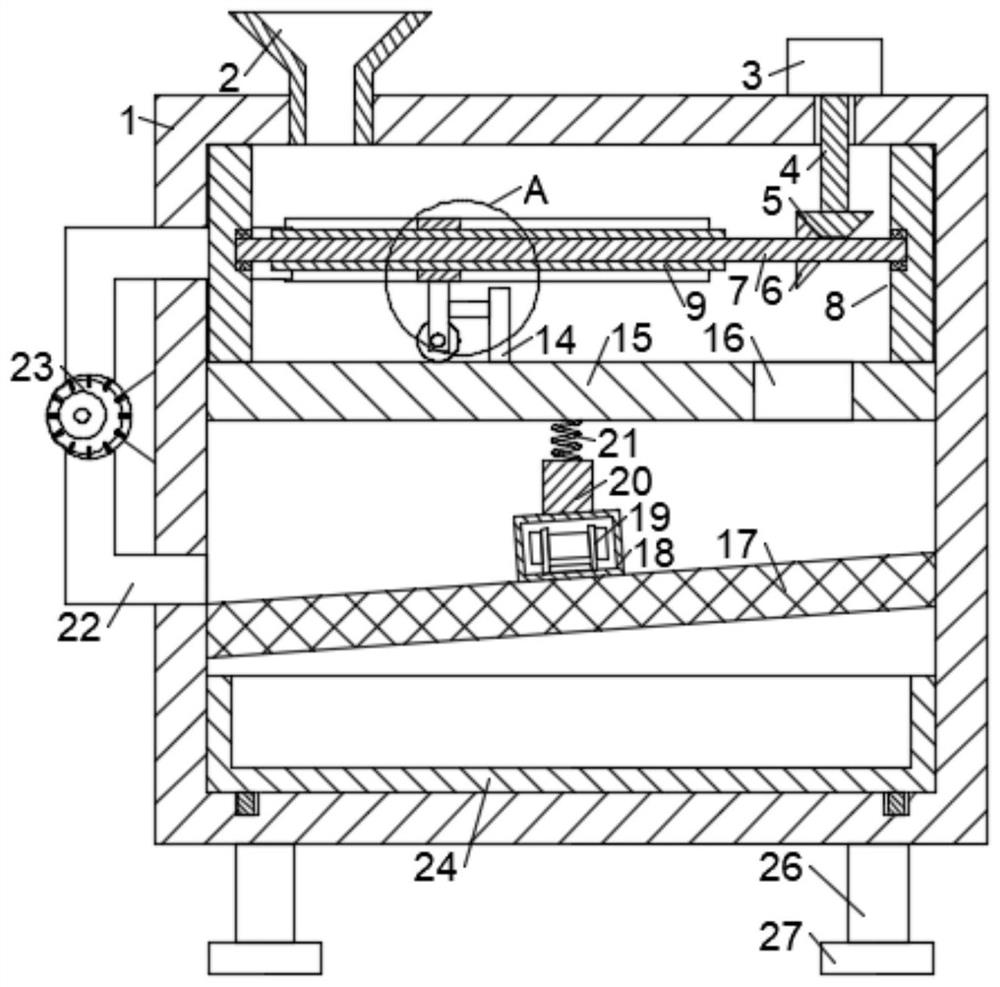

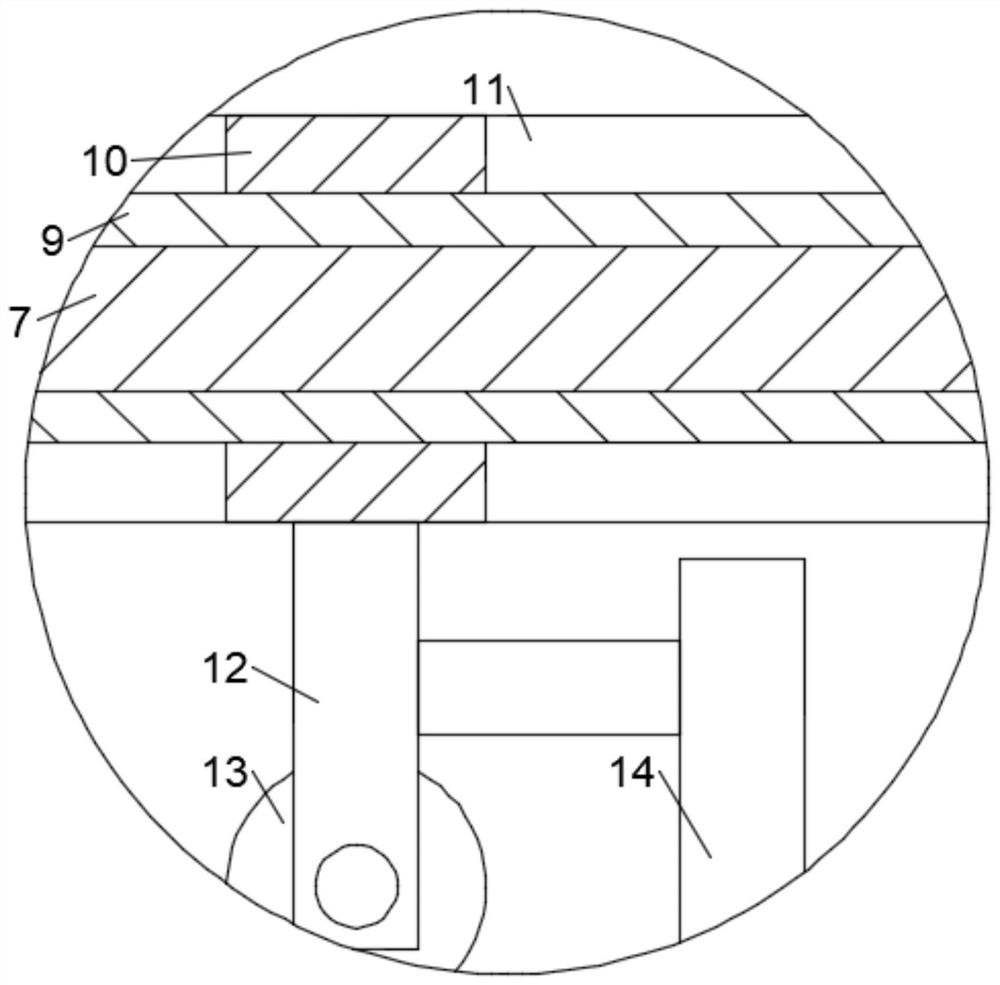

[0021] see Figure 1-3 , in an embodiment of the present invention, a grinding device for grain processing includes a grinding box 1, a feed hopper 2 is connected to the left side above the surface of the grinding box 1, and a feeding hopper 2 is connected to the right side above the surface of the grinding box 1 to realize left and right A moving grinding assembly, which runs through the wall of the grinding box 1 and extends into the box of the grinding box 1, and is connected with a grinding table 15, and the surface of the grinding table 15 is fixedly connected with the grinding box along the center line. 1 The fixed rod 8 fixedly connected to the top of the box body, the upper right side of the grinding table 15 is provided with a through hole 16, the bottom of the grinding box 1 is provided with a drawer 24 slidingly connected to the bottom of the box body of the grinding box 1, and the drawer 24 The surface of the panel is fixedly connected with a handle 25 by screws. ...

Embodiment 2

[0024] see Figure 1-2 , in an embodiment of the present invention, the four corners of the bottom surface of the grinding box 1 are fixedly connected with fixed legs 26 symmetrically.

[0025] In the embodiment of the present invention, fixed legs 26 are provided to fix and support the grinding box 1, and the height of the device is raised to avoid that the device is located in a low-lying place when it rains, and the rainwater causes the food to deteriorate due to moisture.

Embodiment 3

[0027] see Figure 1-2 , in the embodiment of the present invention, the bottom end of the fixed leg 26 is fixedly connected with a foot pad 27 .

[0028] In the embodiment of the present invention, foot pads 27 are provided to play a buffering role, and the force generated when the grinding assembly acts to buffer it, so as to avoid causing noise pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com