Coating method of metal coat with stereo pattern

A technology of metal coating and pattern, applied in the direction of technology for producing decorative surface effects, decorative art, special art surface treatment, etc., can solve the problem of unsatisfactory, low grade and quality, and inability to meet the personalized and modern sense of modern life. and high-grade issues, to achieve the effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

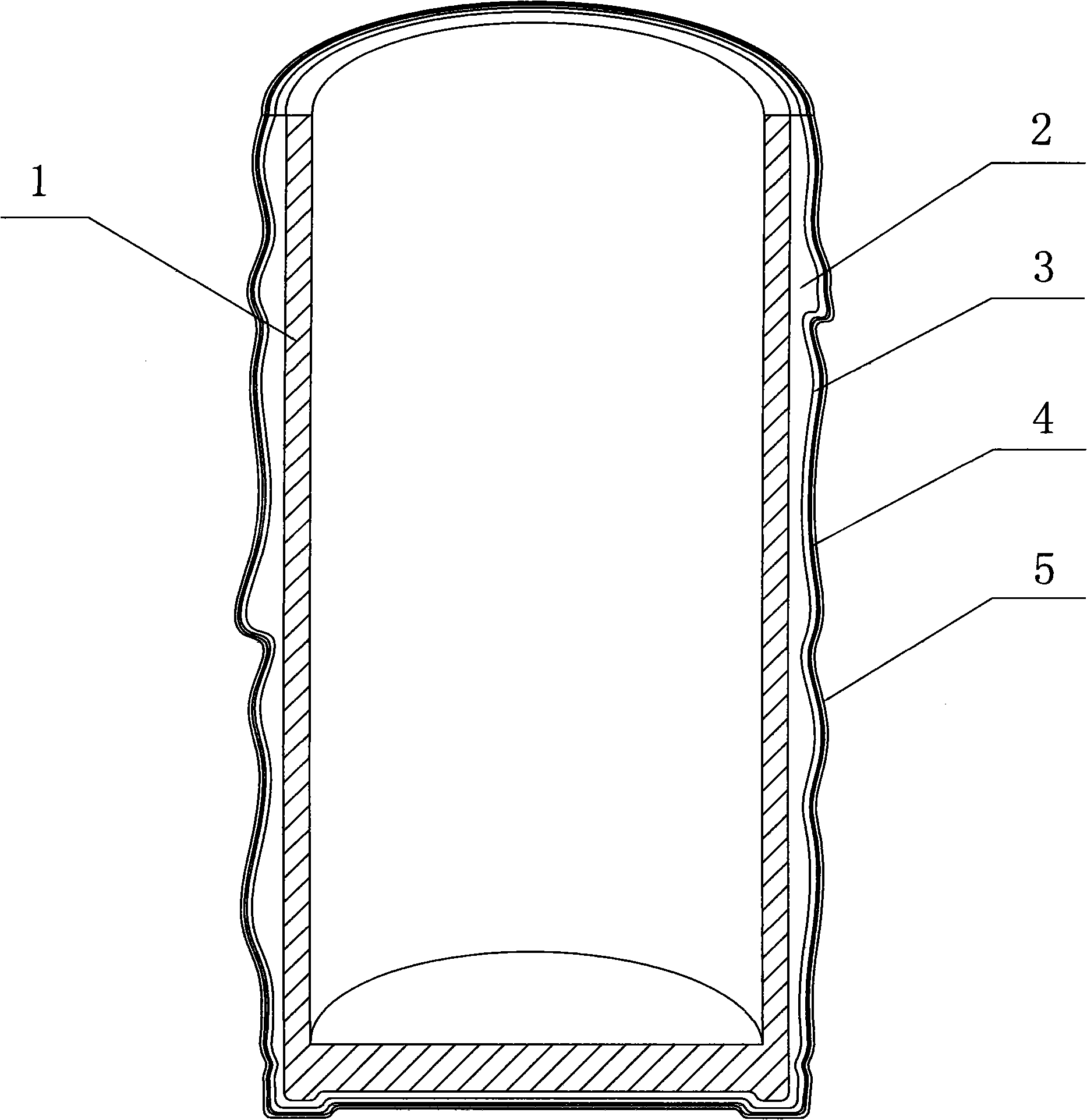

[0027] As shown in the accompanying drawings, a metal three-dimensional craft product is composed of a carrier layer, an epoxy coating layer, a metal layer, a decorative layer and a protective layer. The glue coating layer, electroforming a layer of metal layer on the glue coating layer, a decorative layer made of gold or silver is attached to the metal layer, the decorative layer is coated with a protective layer, the carrier layer, the glue coating layer , metal layer, decorative layer and protective layer are solidly integrated into one structure.

[0028] When attaching the epoxy coating layer on the carrier, use the previously made silicone film, set the silicone film on the carrier, and pour the crystal epoxy forming material between the silicone film and the carrier, because the replication on the silicone film is made by embossing method The three-dimensional pattern is solidified for 2-8 hours, and the film is peeled off to form a glue-coated wrapping layer, on which ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap