Packaging device and box of flat glass plate for displaying

A technology for glass plates and displays, applied in packaging, clamping devices, transportation and packaging, etc., can solve the problems of glass plate side falling and damage, etc., and achieve the effect of convenient use and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

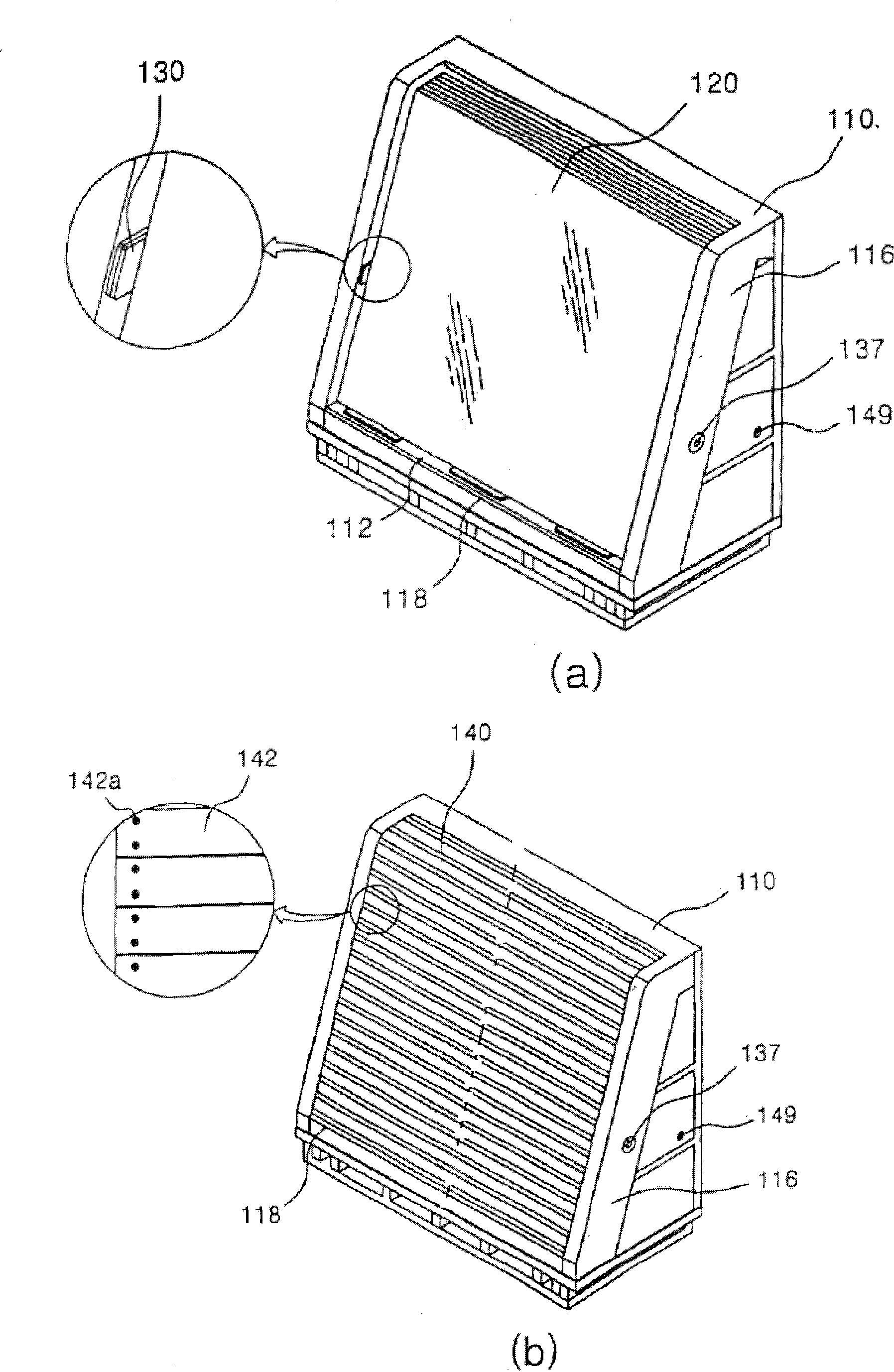

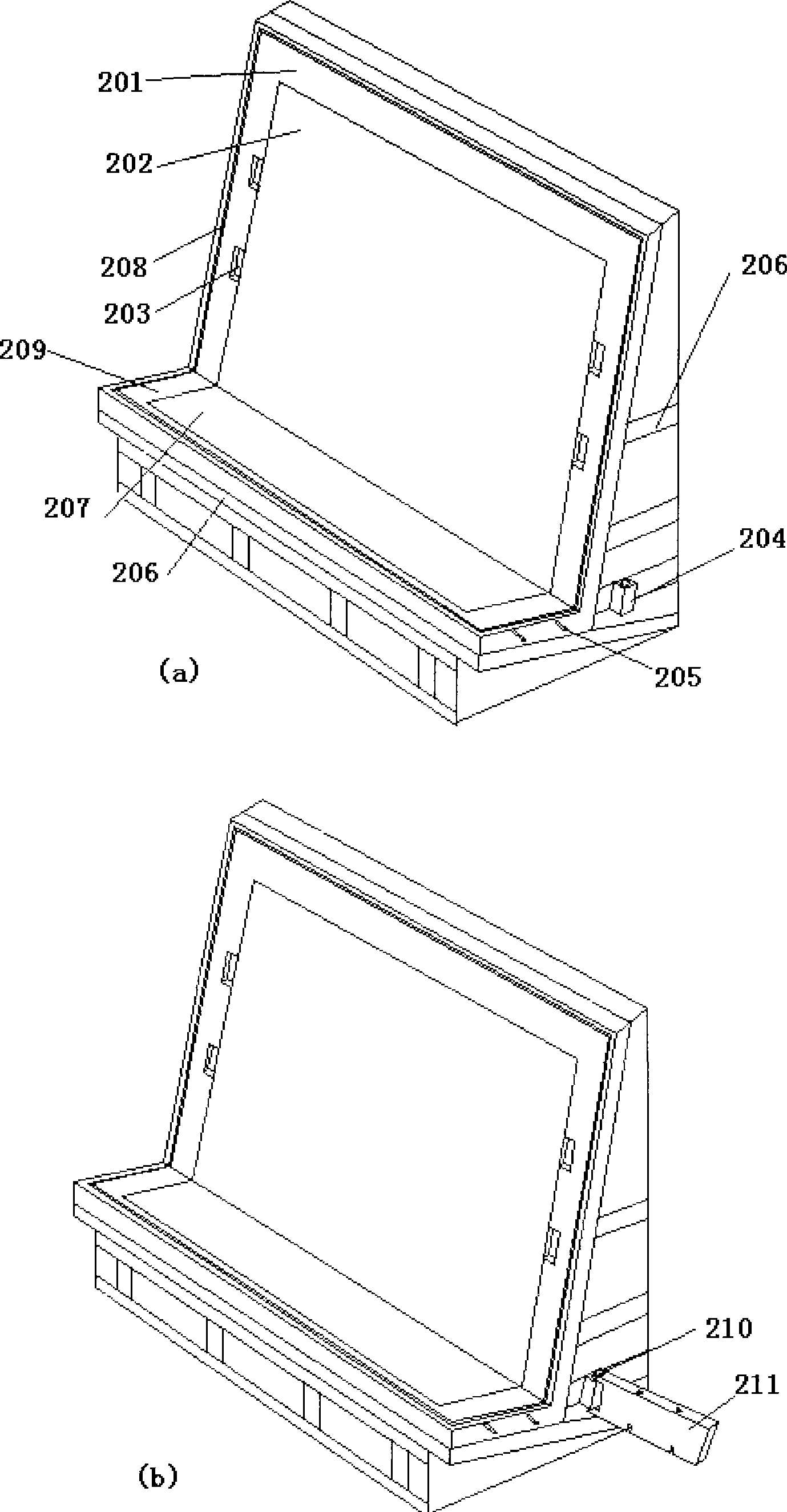

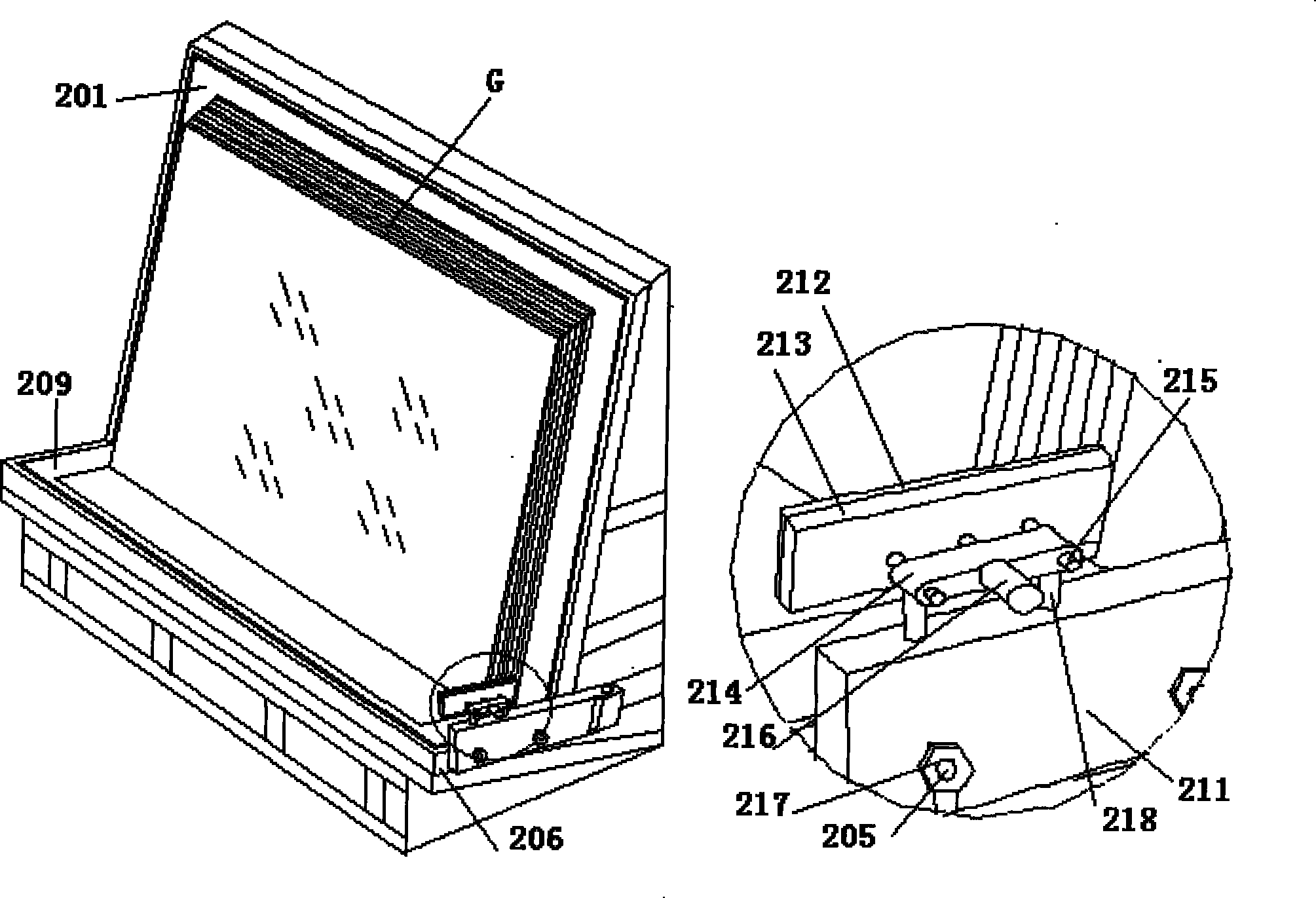

[0032] The following is attached figure 2 , 3 , 4, 5 are detailed descriptions of the desired implementation form of the present invention.

[0033] Reference figure 2 (a) and (b), the basic frame part of the packaging device of the flat glass plate for display based on the present invention will be explained, figure 2 It is an oblique view of the basic frame of the packaging device for flat glass plates for displays based on the present invention. Figure (a) is a state diagram with the rotating block removed, and Figure (b) is a state diagram with the rotating block installed. The basic frame of the packaging device for flat glass plates for displays of the present invention includes the following parts: the mounting frame 206 is composed of a mounting surface 209 at an angle of 5-35° to the horizontal direction and a backrest 201 perpendicular to the mounting surface. The left and right bosses 204 are respectively fixed at the relative positions on both sides of the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com