Method for preparing dibromomethane and methylene chlorobromide by one-pot

A technology of dibromomethane and bromochloromethane, applied in the direction of halogen substitution preparation, organic chemistry, etc., can solve the problems of bromochloromethane selectivity reduction, influence on reaction, etc., achieve the effect of increasing product yield and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

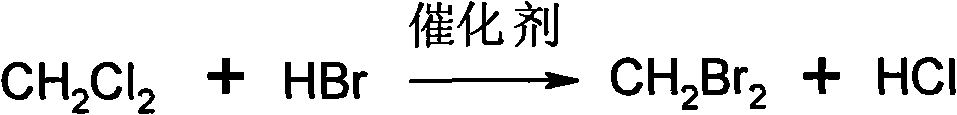

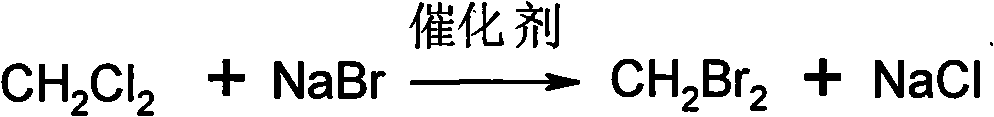

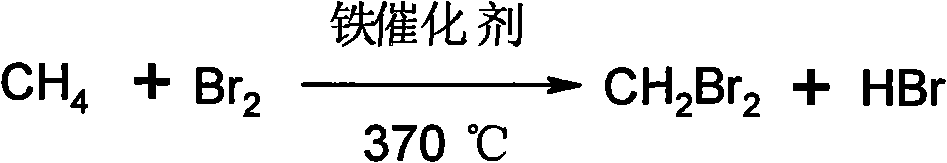

Method used

Image

Examples

Embodiment

[0045] Embodiment, one-pot method produces the preparation method of methylene bromide, bromochloromethane, and described preparation method comprises the following steps:

[0046] ①Hydrogen production process

[0047] Make a solution of methanol and pure water in a weight ratio of 1:1, inject it into the reactor with a metering pump, and produce H under the conditions of mixing and pressurizing to 280°C. 2 , CO 2 , through pressure swing adsorption and purification treatment to obtain hydrogen with a purity of 99.9%;

[0048] ②Hydrogen bromide synthesis process

[0049]Turn on the quartz resistance furnace, and when the temperature of the furnace rises to 700°C, open the exhaust valve, flush nitrogen to replace the air in the calciner, and mix 3.1kg of purified hydrogen with 229.4kg of bromine, that is, the molar ratio is 1:1 Pass it into a quartz glass synthesis furnace at a temperature of 700°C to synthesize hydrogen bromide gas, then debrominate it, dry it with molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com