Method of preparing polypropylene multi-layer nonwoven fabrics for medical treatment

A manufacturing method and technology of non-woven fabrics, applied in the direction of textiles and papermaking, textile material processing, application, etc., can solve the problems of increasing usage, reducing water resistance, and not easy to improve water resistance, so as to reduce burden, save energy and The effect of washing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

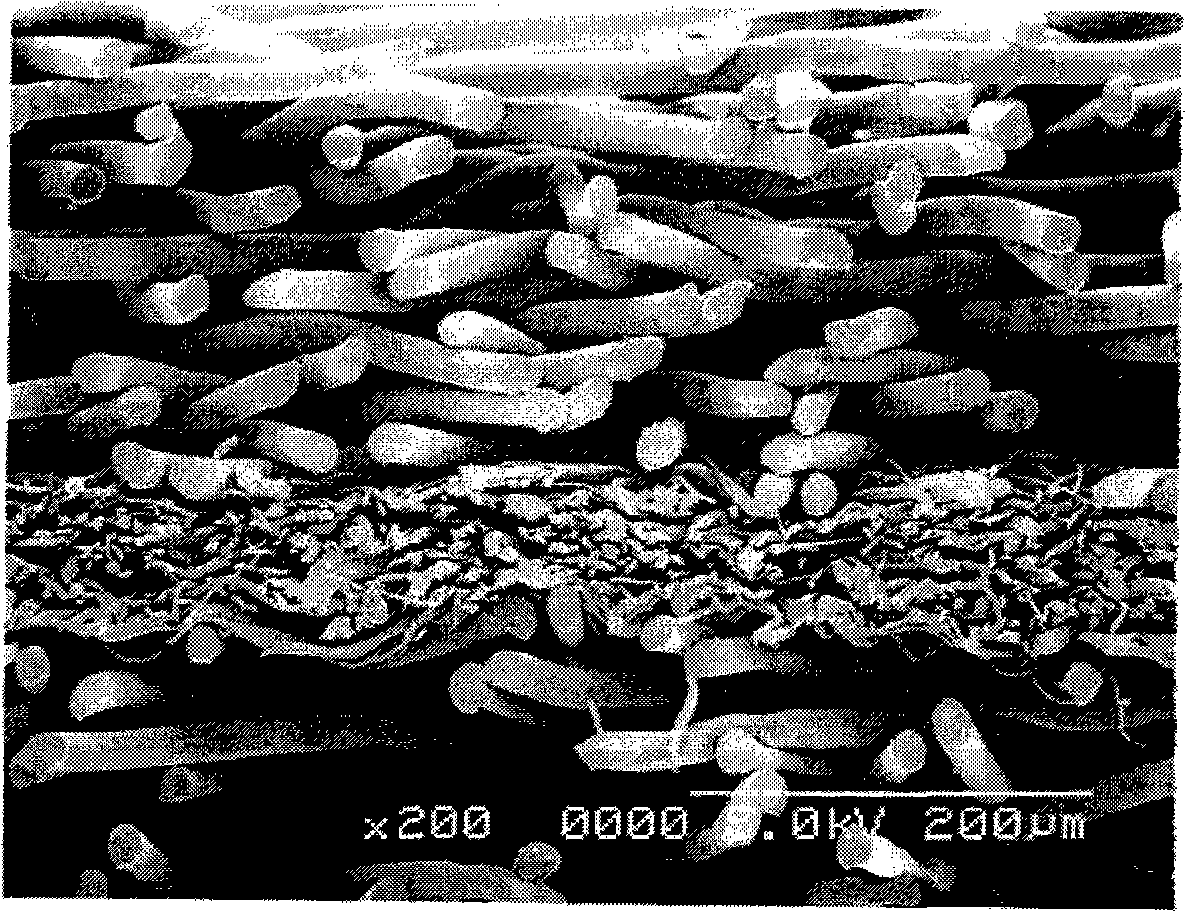

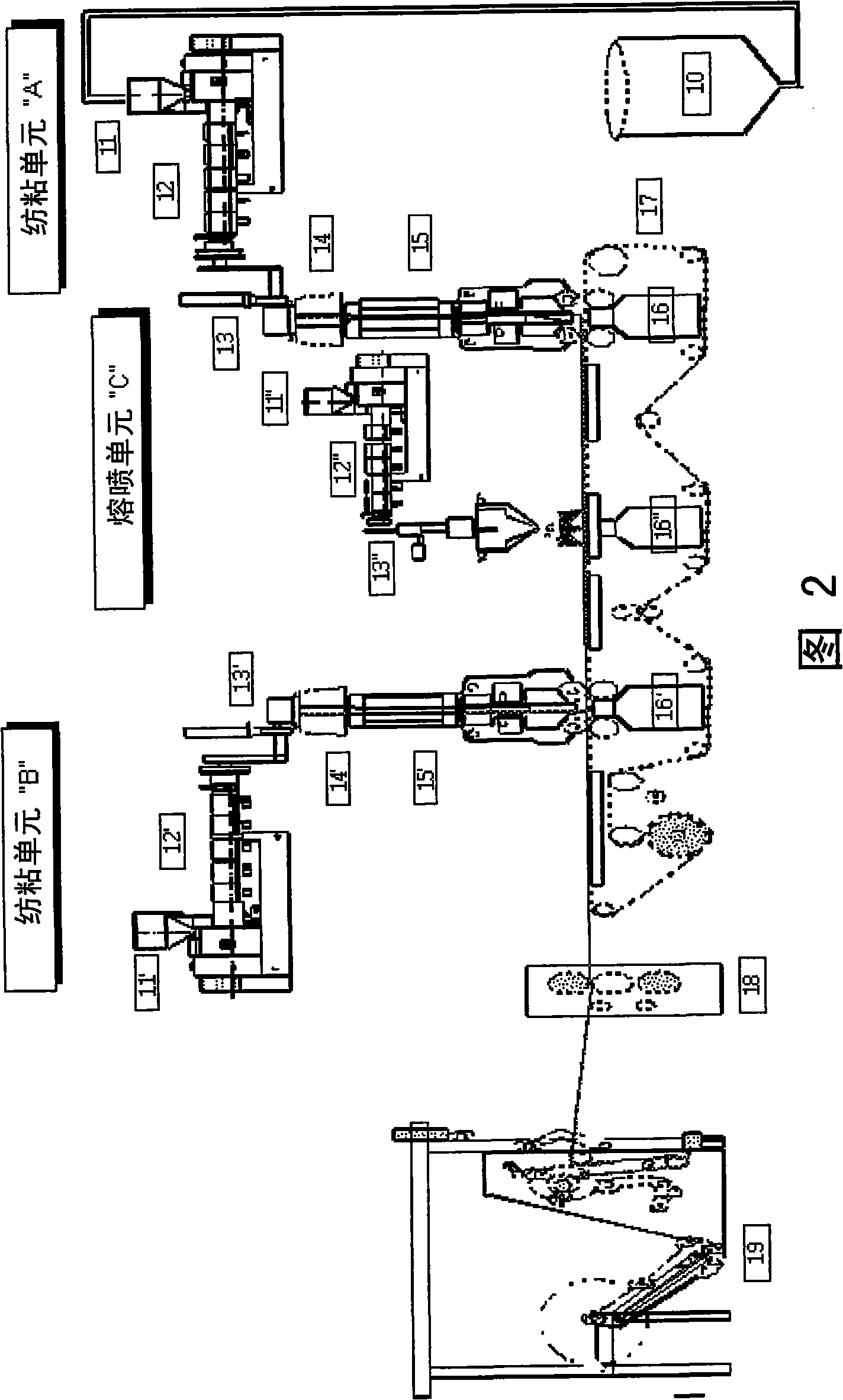

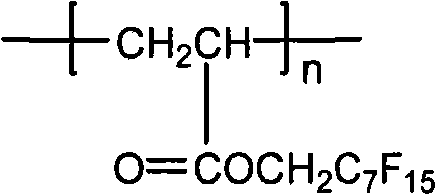

[0077] The spunbond main raw material of the present invention is polypropylene with a melt index (MFR) of 35 g / 10 minutes. In order to reflect the blue color, 3% by weight of a master batch of highly concentrated phthalocyanine blue dye is added. Melt and mix the main raw materials and masterbatch sheets in the extruder, after passing through the spinneret to form filaments, cool them with a cooler, suck in air from the lower part of the conveyor belt to extend, and form the first spunbond mesh layer on the continuously moving platform conveyor belt and a second spunbond web layer. Melt-blown polypropylene with a melt index (MFR) of 1000 g / 10 min. Blue masterbatch was used as in the spunbond layer. Melt and mix the main raw material and the masterbatch sheet in the extruder, spin through a porous spinneret, and extend the polymer, and the extended polymer forms a melt-blown network layer according to 1-5 μm fine lines. The third melt-blown net layer is a two-layer structure,...

Embodiment 2

[0079] Except the overall weight of non-woven fabric is 60g / m 2 , The temperature of the hot air dryer is the same as in Example 1 except that it is 145°C. Conditions and physical properties are shown in Table 2 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com