Hollow mold for filling cast-in-situ concrete

A hollow carcass, cast-in-place concrete technology, applied in the direction of floor slabs, building materials, building components, etc., to achieve the effects of simple construction, light structure, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

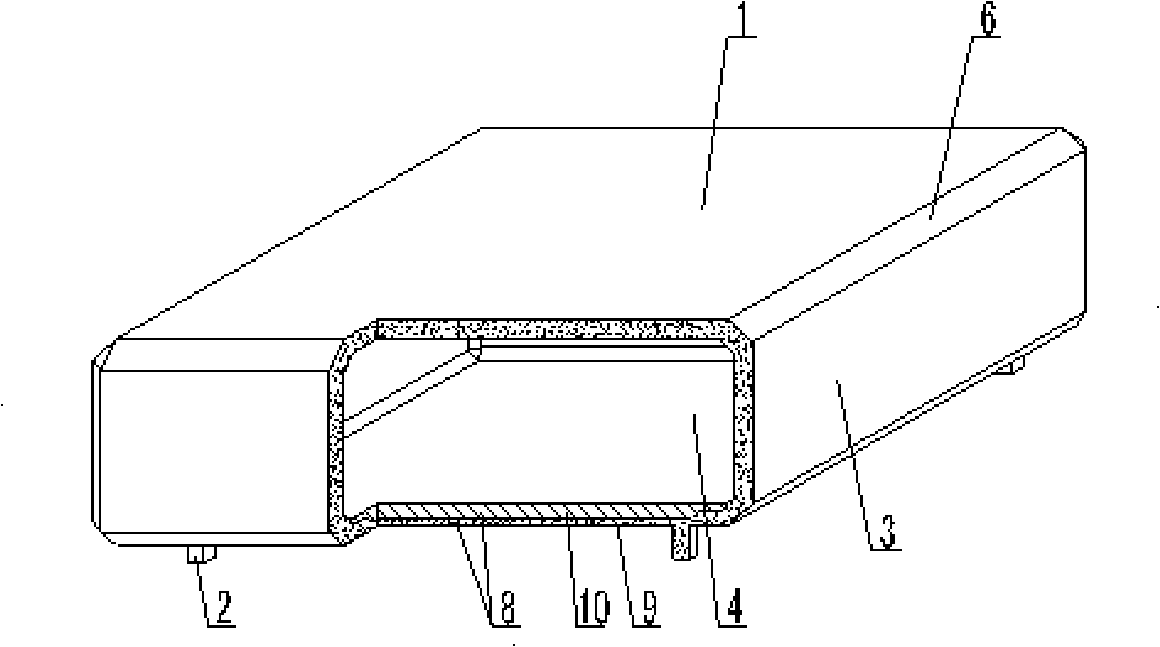

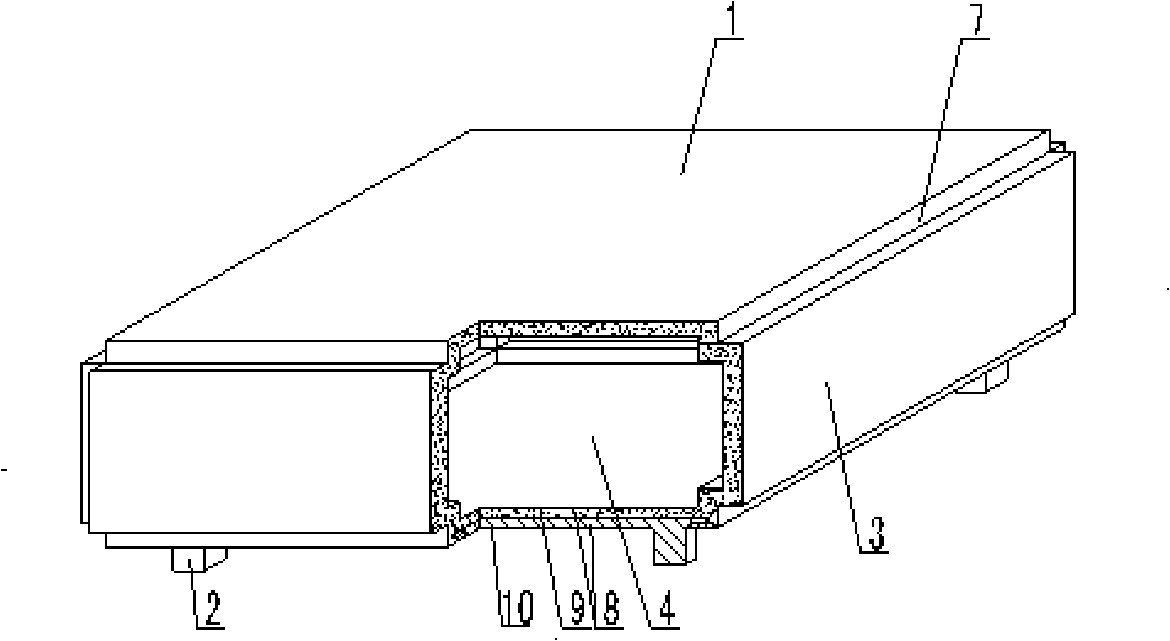

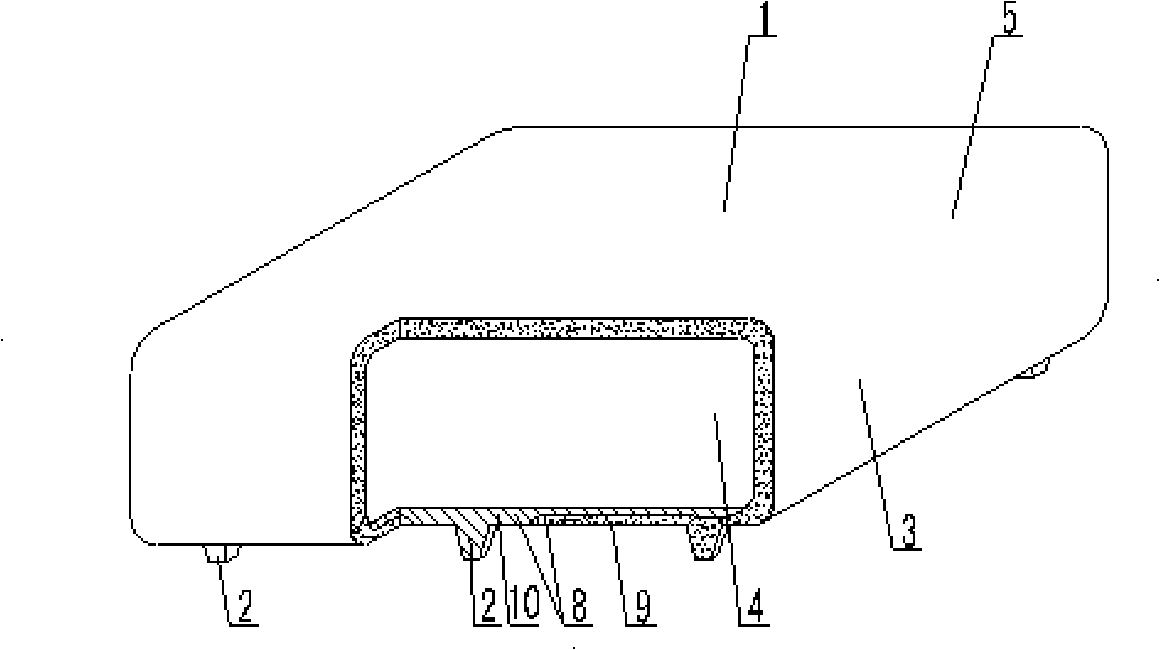

[0078] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0079] As shown in the accompanying drawings, the present invention includes a hollow carcass 1 and a support foot 2. The support foot 2 is arranged on the outer wall 3 of the bottom surface of the hollow carcass 1, and the outer wall 3 encloses the hollow carcass 1 with a cavity 4. Its characteristics The corner where the at least two surfaces intersect is an arc angle 5 or a chamfer 6 or an inner corner 7 or a combination thereof, and at least one support foot 2 is connected to the outer wall 3 containing a prefabricated cast-in-place laminated laminated layer 8, and the laminated The composite layer 8 includes a cast-in-place layer 9 and a prefabricated layer 10 , reinforcements 14 are arranged in the embryo body of the outer wall 3 , and reinforcements 18 are arranged in the cavity 4 . In each drawing, 1 is the hollow carcass, 2 is the support foot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com