Color wheel

A color wheel and end cap technology, applied in the field of color wheels, can solve problems such as product quality degradation, color filter translocation, falling off, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

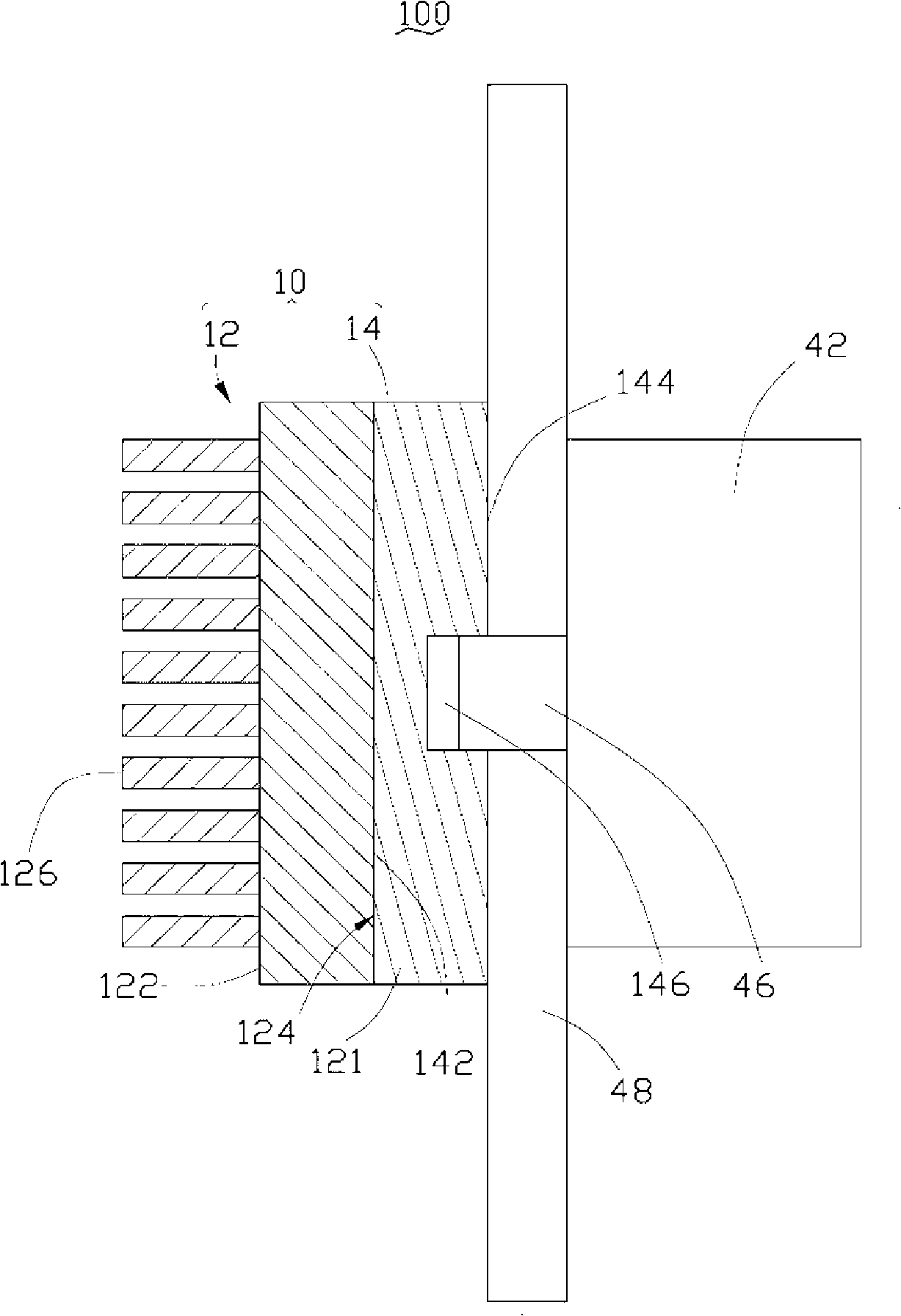

[0016] see figure 2 , the first preferred embodiment of the color wheel of the present invention, the color wheel 100 includes a motor 42 , a filter 48 and an end cap 10 . The motor 42 includes a shaft 46 . The filter 48 is sheathed on the shaft 46 of the motor 42 . The end cover 10 is fixed on the end of the motor shaft 46 such that the filter 48 is sandwiched between the motor 42 and the end cover 10 .

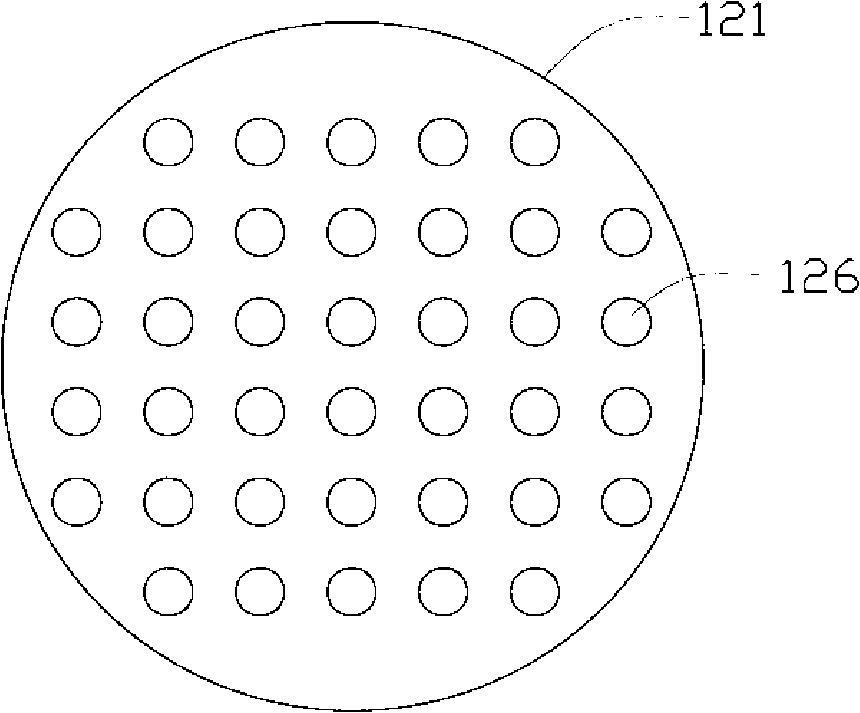

[0017] The end cover 10 includes a heat dissipation portion 12 and a connection plate 14 , and the heat dissipation portion 12 is fixed on the connection plate 14 . The heat dissipation portion 12 and the connecting plate 14 are made of thermally conductive materials such as metals and thermally conductive polymer materials. The size and shape of the heat dissipation portion 12 and the connecting plate can be designed according to the color wheel to which the end cover 10 is applied. In this implementation, preferably, the heat dissipation portion 12 and the connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com