Synchronization triggering on-line diagnostic method and system for photoetching machine

A technology for synchronizing triggering and diagnosing systems, applied in microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problems of asynchronous data timing, inability to locate synchronous timing, and inability to quickly locate lithography machine problems, etc. Achieve the effect of rapid positioning, saving time for integration and technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

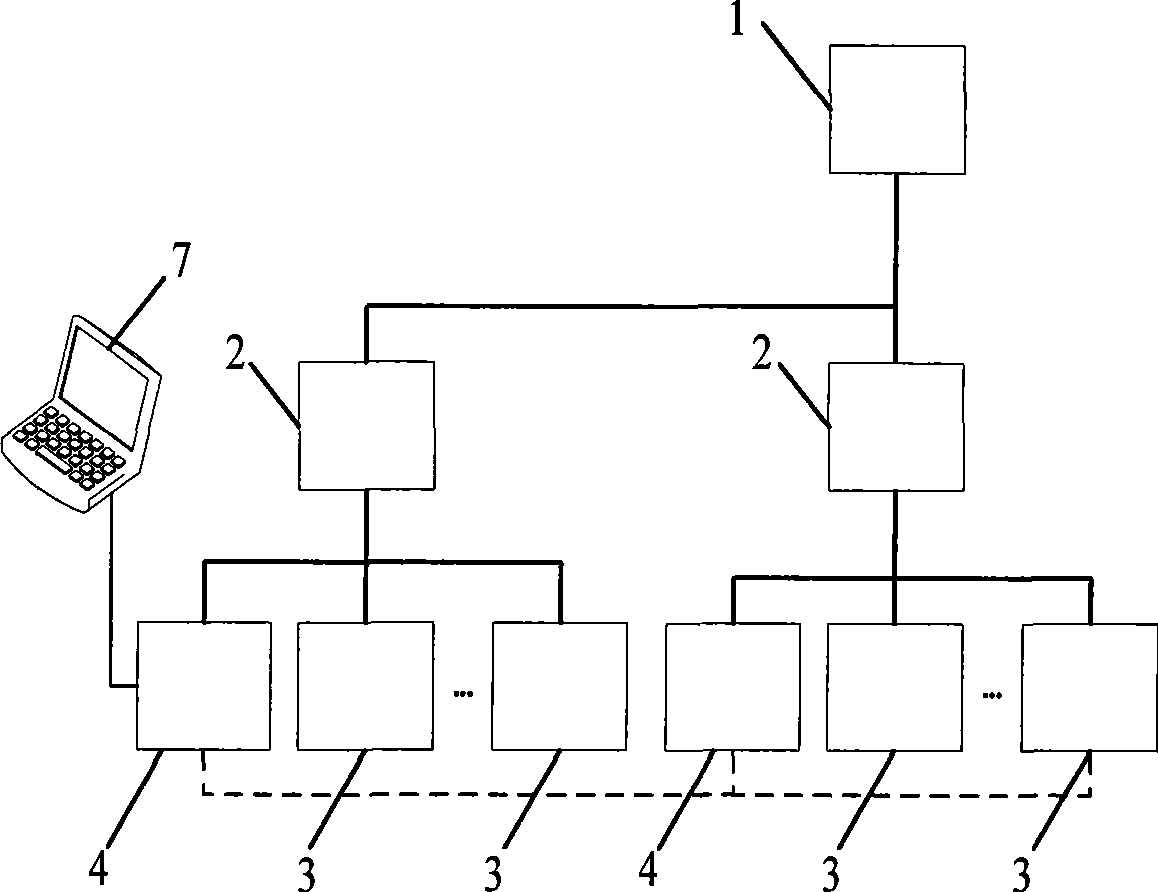

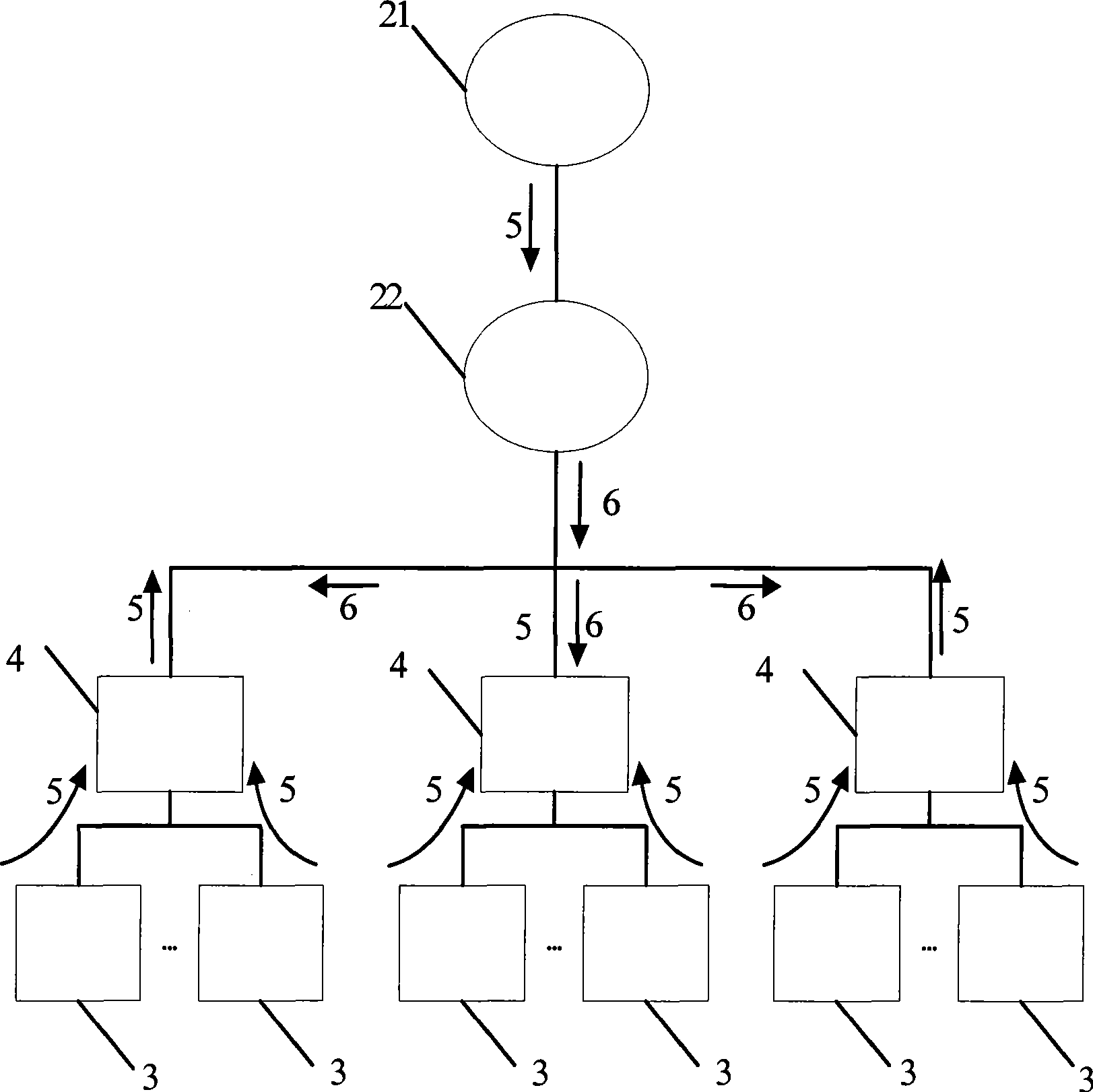

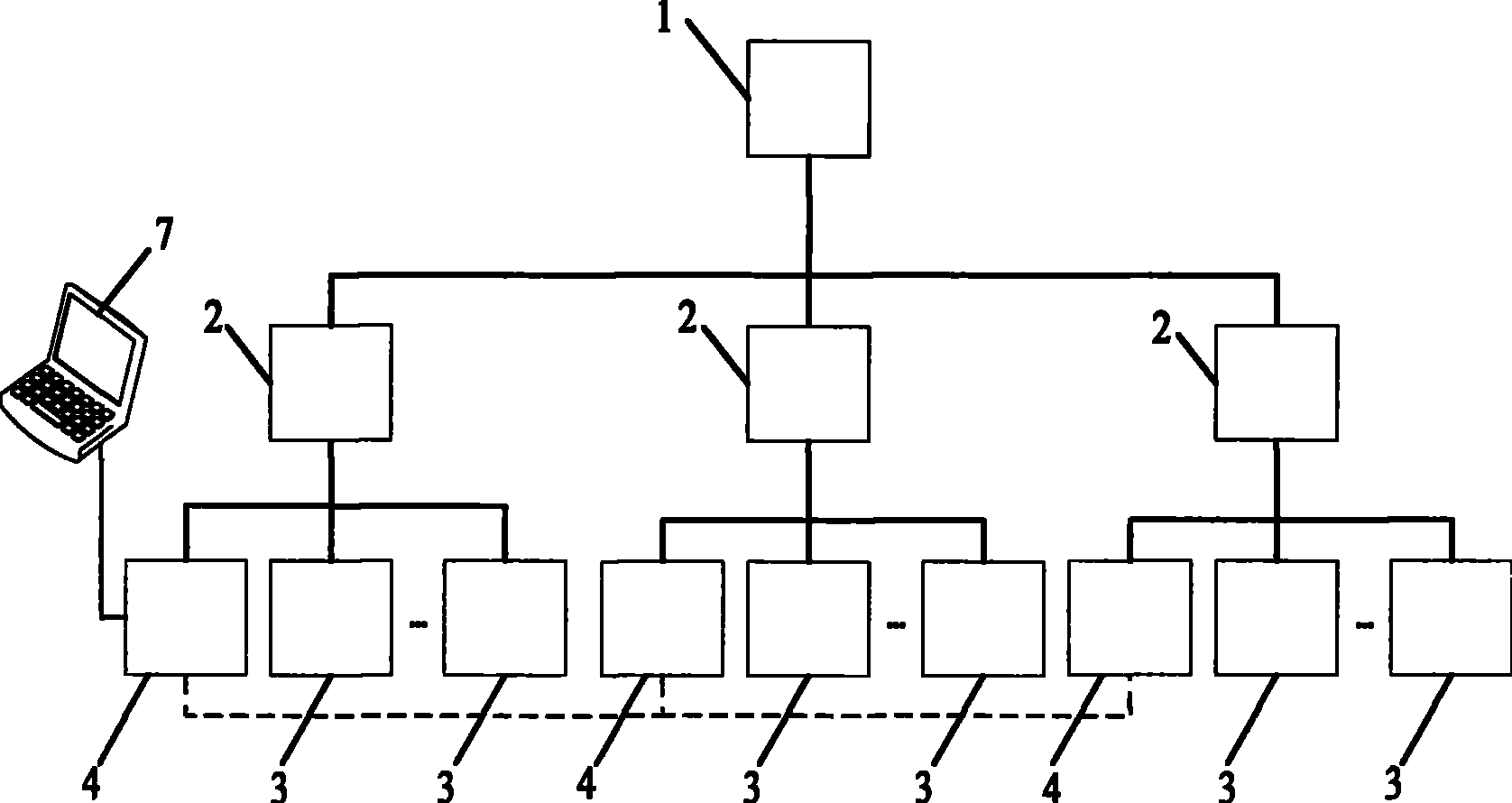

[0037] Such as figure 1 As shown, the present invention provides a synchronous trigger diagnosis system for a lithography machine comprising two subsystems, including: a main controller 1; two subsystem controllers 2; two trigger diagnosis buffer boards 4; three sub-systems System control daughter card 3.

[0038] Such as figure 1In the system shown, the trigger diagnosis buffer board 4 exists in each subsystem of the lithography machine system, and the trigger diagnosis buffer board 4 and the subsystem controller 2, the subsystem control daughter card 3, and the subsystem control daughter card 3 They are connected through the standard VME bus. The trigger diagnosis buffer boards 4 are connected through hardware synchronization signal lines. These trigger diagnostic buffer boards provide a special ring buffer for storing the diagnostic data on the subsystem controller 2 and the subsystem control daughter card 3 . The main controller 1 and the subsystem controller 2 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com