A kind of manufacturing method of green light emitting diode

A technology of light-emitting diodes and manufacturing methods, which can be applied to semiconductor devices, electrical components, circuits, etc., and can solve problems such as low external quantum efficiency and poor antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

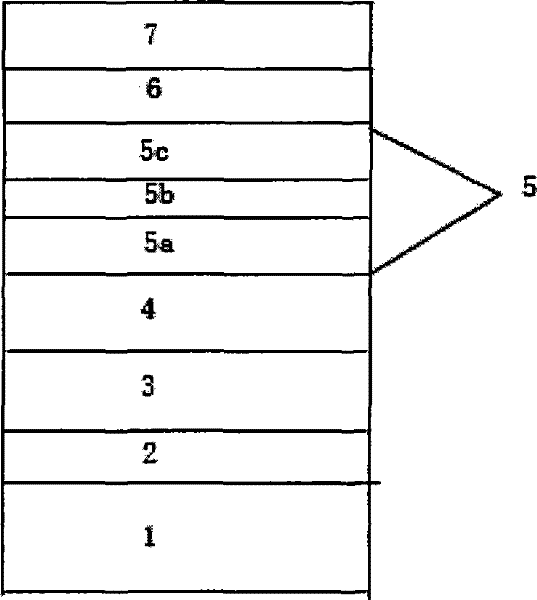

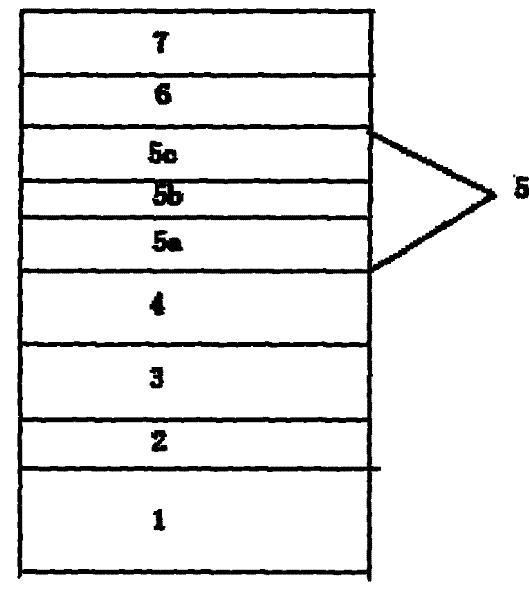

Embodiment 1

[0022] Using MOCVD equipment to epitaxially grow high-brightness green light-emitting diodes, the substrate used is (001) sapphire. Such as figure 1 As shown, firstly, the sapphire substrate 1 is heated to 1200°C in the MOCVD reaction chamber, treated under H2 for 5 minutes, and then the temperature is lowered to 500-600°C to grow the GaN nucleation layer 2 with a thickness of about 30nm; then the temperature is raised to 1160°C , H2 as carrier gas, epitaxially grown a 4-micron-thick GaN buffer layer at a growth rate of 3.0 microns / hour, including a 0.5-micron-thick unintentionally doped GaN layer 3 and a 3.5-micron-thick Si-doped n-type GaN buffer layer 4. The doping concentration of silicon is 5×10 17 cm -3 up to 5×10 19 cm -3 between; then lower the temperature to 650-750°C, switch the carrier gas to N2, and grow 5 In on the buffer layer 0.2 Ga 0.8 N(2.5nm) / In 0.8 Ga 0.2 N(0.5nm) / GaN(10nm), where the molar flow of TEGa is 0.1×10 -5 mol / min to 1.5×10 -5 mol / min, th...

Embodiment 2

[0024] Using MOCVD equipment to epitaxially grow high-brightness green light-emitting diodes, the substrate used is (001) sapphire. Such as figure 1 As shown, firstly, the sapphire substrate 1 is heated to 1200°C in the MOCVD reaction chamber, treated under H2 for 5 minutes, and then the temperature is lowered to 500-600°C to grow the GaN nucleation layer 2 with a thickness of about 30nm; then the temperature is raised to 1160°C , H2 as carrier gas, epitaxially grown a 4-micron-thick GaN buffer layer at a growth rate of 3.0 microns / hour, including a 0.5-micron-thick unintentionally doped GaN layer 3 and a 3.5-micron-thick Si-doped n-type GaN buffer layer 4. The doping concentration of silicon is 5×10 17 cm -3 up to 5×10 19 cm -3 between; then lower the temperature to 650-750°C, switch the carrier gas to N2, and grow 5 In on the buffer layer 0.2 Ga 0.8 N(2.5nm) / Al 0.8 Ga 0.2 N(0.5nm) / GaN(10nm), where the molar flow of TEGa is 0.1×10 -5 mol / min to 1.5×10 -5 mol / min, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com