Green light LED

A light-emitting diode and green light technology, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor antistatic ability, low external quantum efficiency, and low external quantum efficiency of green light-emitting diodes, so as to reduce V-type defects , Strong antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

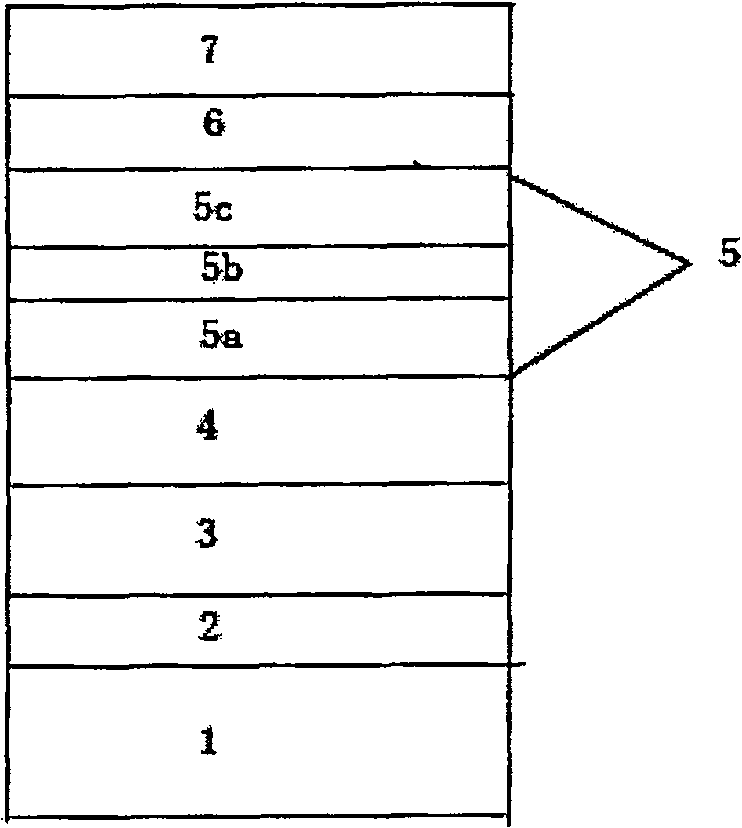

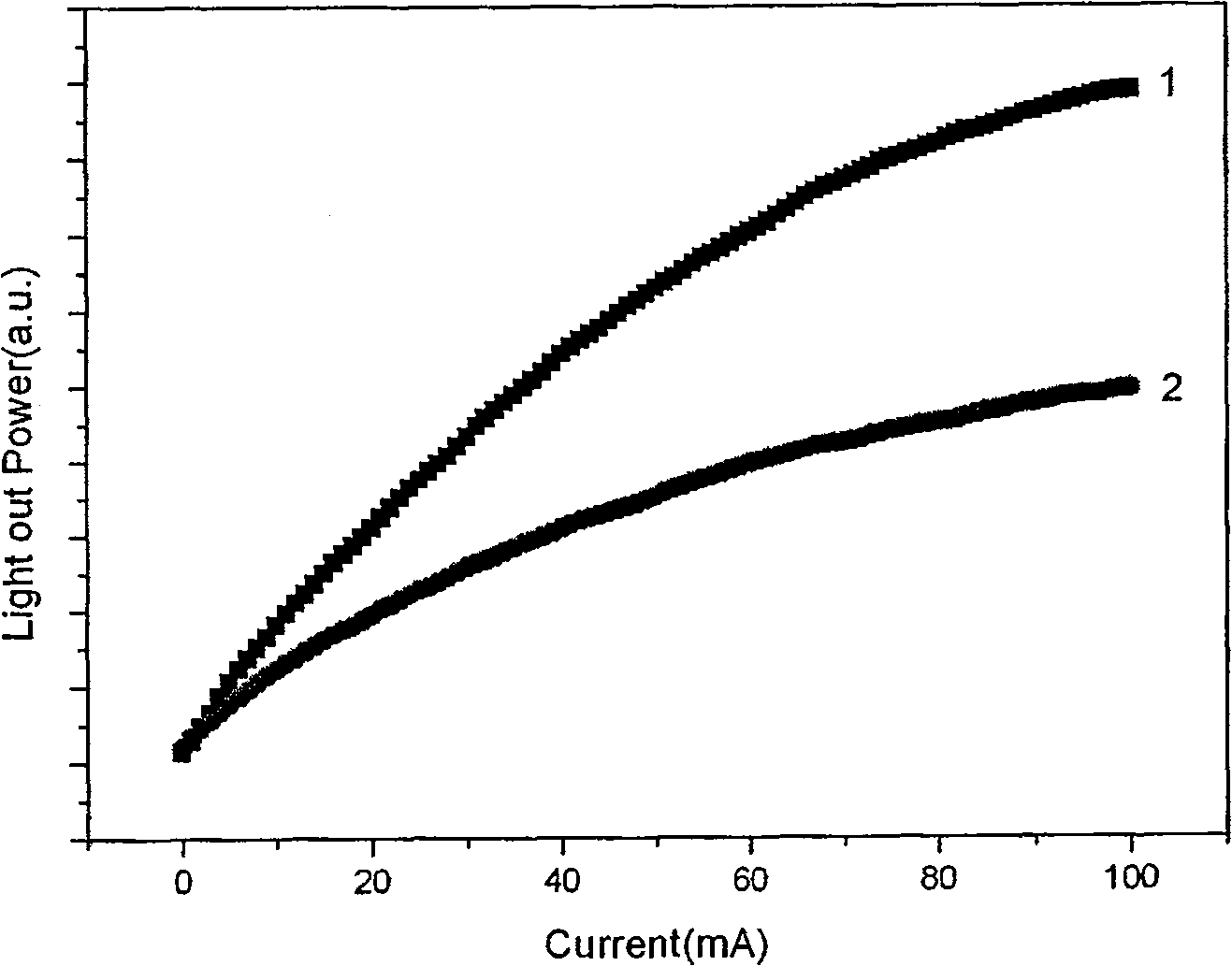

[0023] Using MOCVD equipment to epitaxially grow high-brightness green light-emitting diodes, the substrate used is (001) sapphire. Such as figure 1 As shown, firstly, the sapphire substrate 1 was heated to 1200 °C in the MOCVD reaction chamber, under H 2 The temperature is lowered for 5 minutes, and then the temperature is lowered to 500-600°C to grow a GaN nucleation layer 2 with a thickness of about 30nm; then the temperature is raised to 1160°C, and the H 2 As a carrier gas, epitaxially grow a 4-micron thick GaN buffer layer at a growth rate of 3.0 microns / hour, including a 0.5-micron thick unintentionally doped GaN layer 3 and a 3.5 micron-thick Si-doped n-type GaN buffer layer 4, The doping concentration of silicon is 5×10 17 cm -3 up to 5×10 19 cm -3 between; then lower the temperature to 650-750°C, switch the carrier gas to N 2 , grow 5 In on this buffer layer 0.2 Ga 0.8 N(2.5nm) / In 0.8 Ga 0.2 N(0.5nm) / GaN(10nm), where the molar flow of TEGa is 0.1×10 -5 mol...

Embodiment 2

[0025] Using MOCVD equipment to epitaxially grow high-brightness green light-emitting diodes, the substrate used is (001) sapphire. Such as figure 1 As shown, firstly, the sapphire substrate 1 was heated to 1200 °C in the MOCVD reaction chamber, under H 2 The temperature is lowered for 5 minutes, and then the temperature is lowered to 500-600°C to grow a GaN nucleation layer 2 with a thickness of about 30nm; then the temperature is raised to 1160°C, and the H 2 As a carrier gas, epitaxially grow a 4-micron thick GaN buffer layer at a growth rate of 3.0 microns / hour, including a 0.5-micron thick unintentionally doped GaN layer 3 and a 3.5 micron-thick Si-doped n-type GaN buffer layer 4, The doping concentration of silicon is 5×10 17 cm -3 up to 5×10 19 cm -3 between; then lower the temperature to 650-750°C, switch the carrier gas to N 2 , grow 5 In on this buffer layer 0.2 Ga 0.8 N(2.5nm) / Al 0.8 Ga 0.2 N(0.5nm) / GaN(10nm), where the molar flow of TEGa is 0.1×10 -5mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com