Bromhexine hydrochloric acid orally disintegrating tablet production method

An orally disintegrating tablet and production method technology, applied in the field of powder feeder for new tablet presses, can solve the problems of inability to realize industrialized production, poor tablet compressibility, tablet weight difference, etc., and achieve cool and delicate taste, high tablet weight Effect of small variance, high dissolution rate and high dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

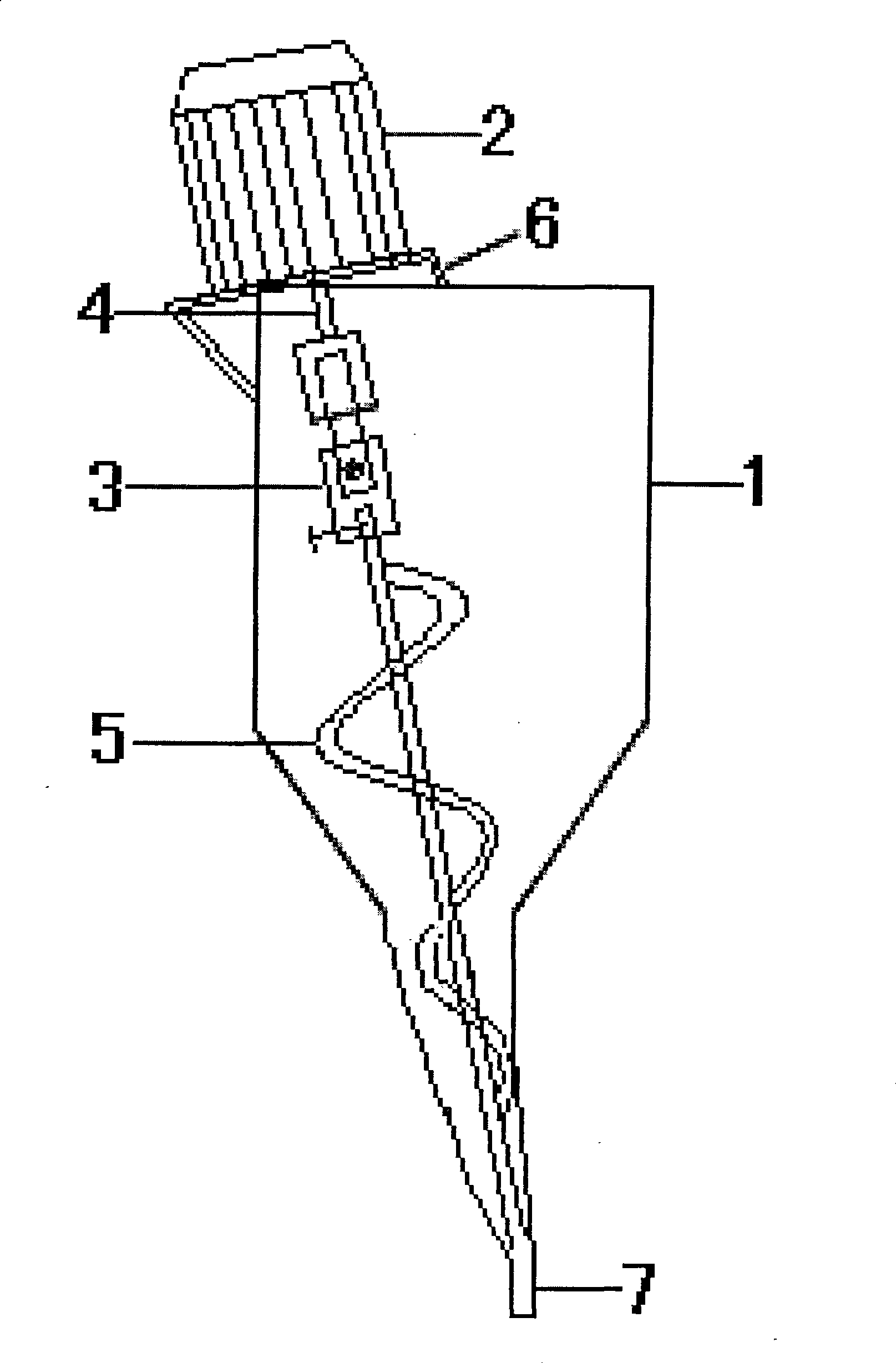

Image

Examples

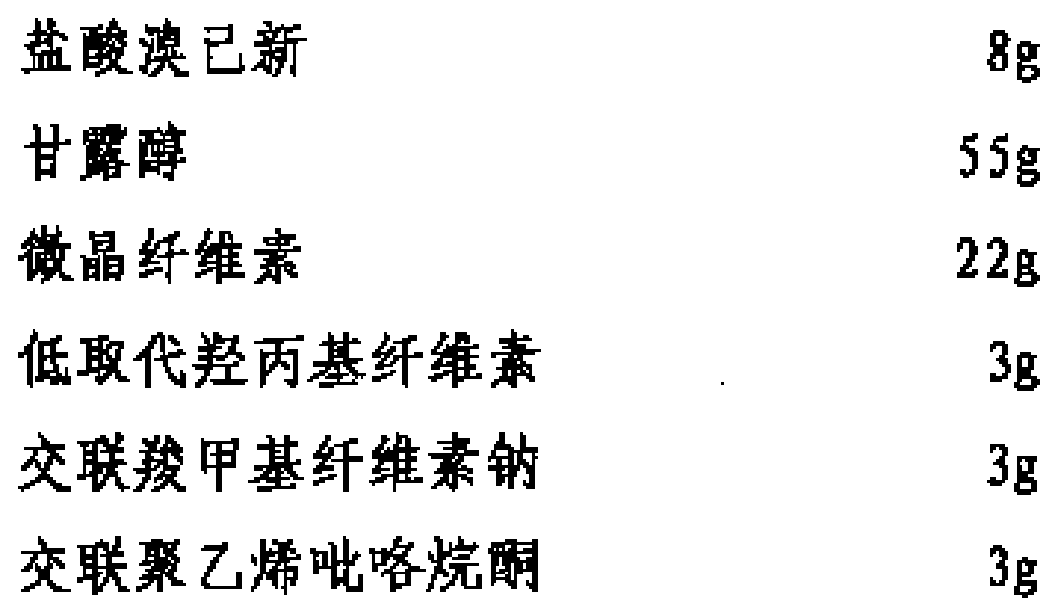

example 1

[0024]

[0025]

[0026] Bromhexine hydrochloride and mannitol, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, croscarmellose sodium, crospovidone, aspartame, micronized silica gel, magnesium stearate After being pulverized separately, mixed and sieved according to the prescription weight ratio, the final mixed fine powder is placed in a powder feeder for a new tablet machine, and compressed into tablets to produce bromhexine hydrochloride orally disintegrating tablets.

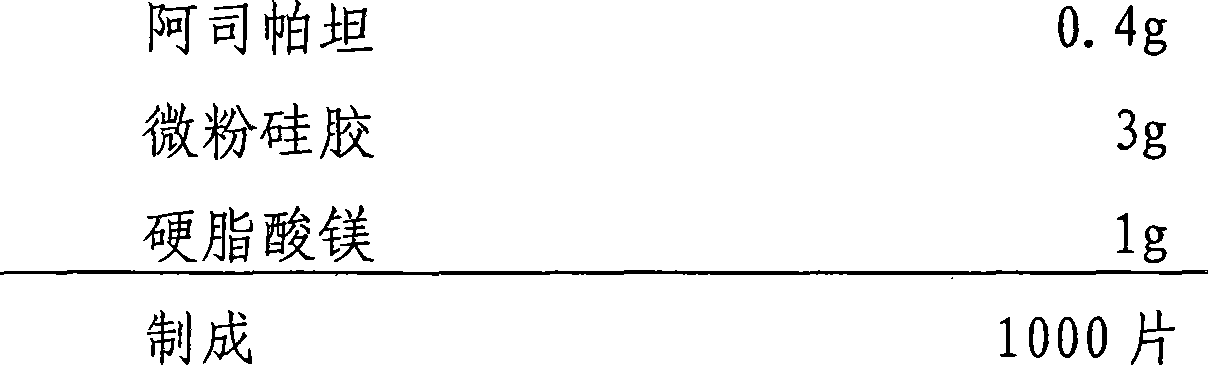

example 2

[0028]

[0029] Bromhexine hydrochloride and mannitol, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, croscarmellose sodium, crospovidone, aspartame, micronized silica gel, magnesium stearate After being pulverized separately, mixed and sieved according to the prescription weight ratio, the final mixed fine powder is placed in a powder feeder for a new tablet machine, and compressed into tablets to produce bromhexine hydrochloride orally disintegrating tablets.

example 3

[0031]

[0032]

[0033]Bromhexine hydrochloride and lactose, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, croscarmellose sodium, crospovidone, aspartame, micronized silica gel, magnesium stearate After pulverization, mix and sieve according to the prescription weight ratio, and put the total mixed fine powder into a powder feeder for a new tablet machine, and compress into tablets to produce bromhexine hydrochloride orally disintegrating tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com