Desk type accurate punching machine

A precision punching and desktop technology, applied in the field of mechanical processing equipment, can solve the problems of large contact area, increased friction coefficient, high machining accuracy requirements of ball joints, and increased energy consumption of brake belts, achieving good braking performance and compact structure. , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

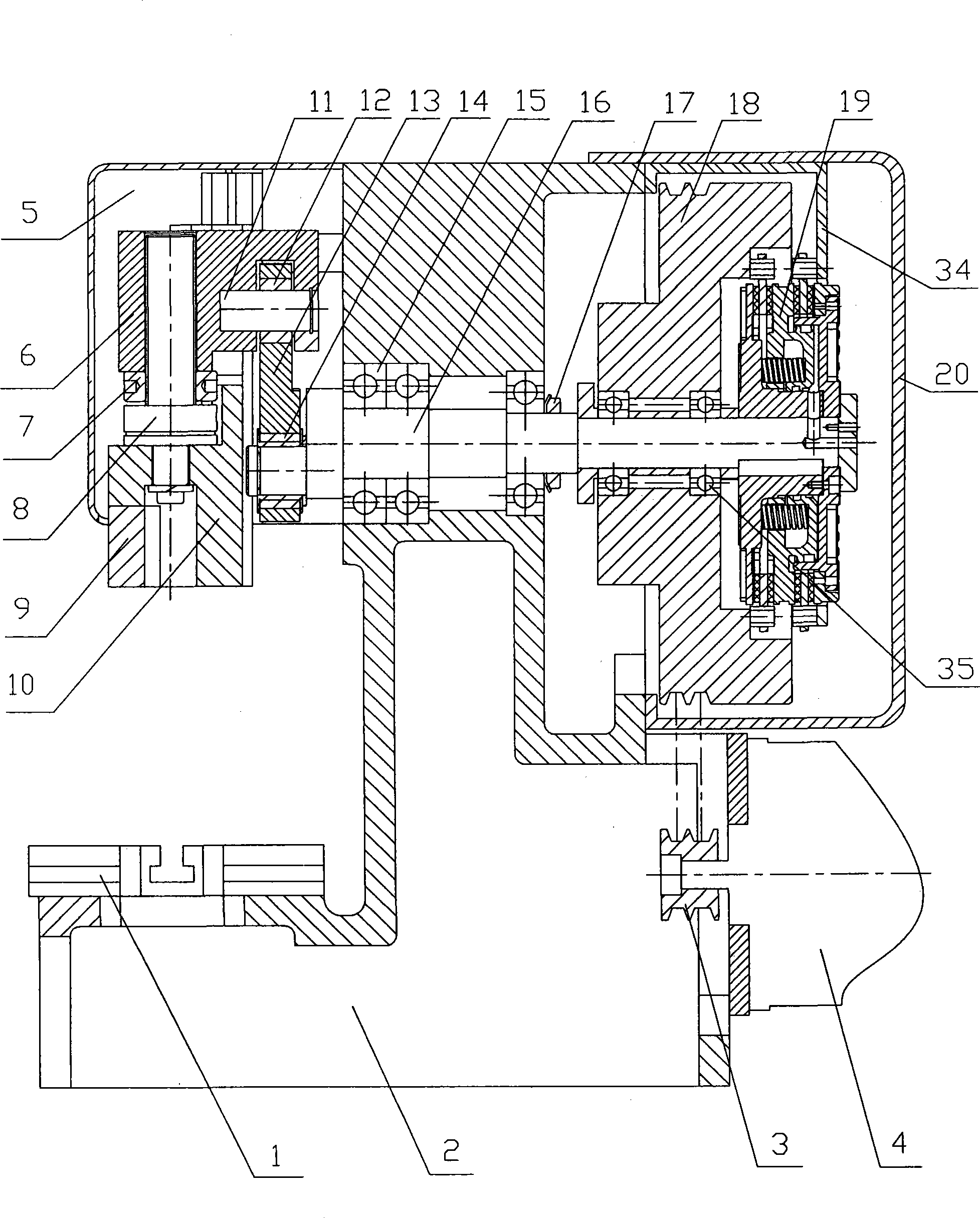

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Workbench 1 and motor 4 are fixedly installed on the surface and side wall of table body 2 respectively, crankshaft 16 is installed on table body 2 through bearing 15, flywheel 18 is installed on crankshaft 16 through flywheel bearing 35, in order to prevent axial movement Also be connected with stop nut 17 on the crankshaft of stage body place, motor 4 drives flywheel 18 by belt pulley 3, belt and rotates.

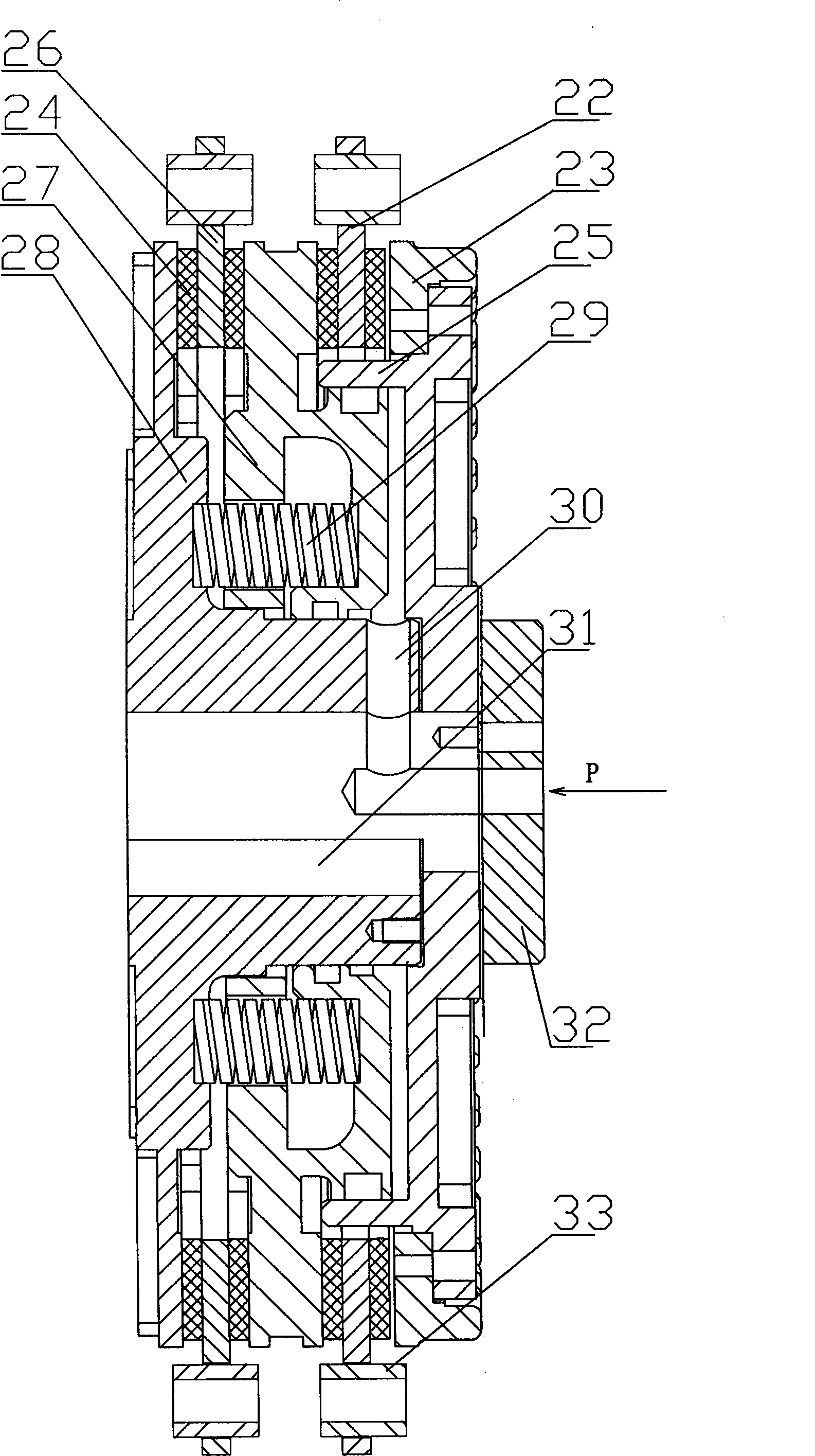

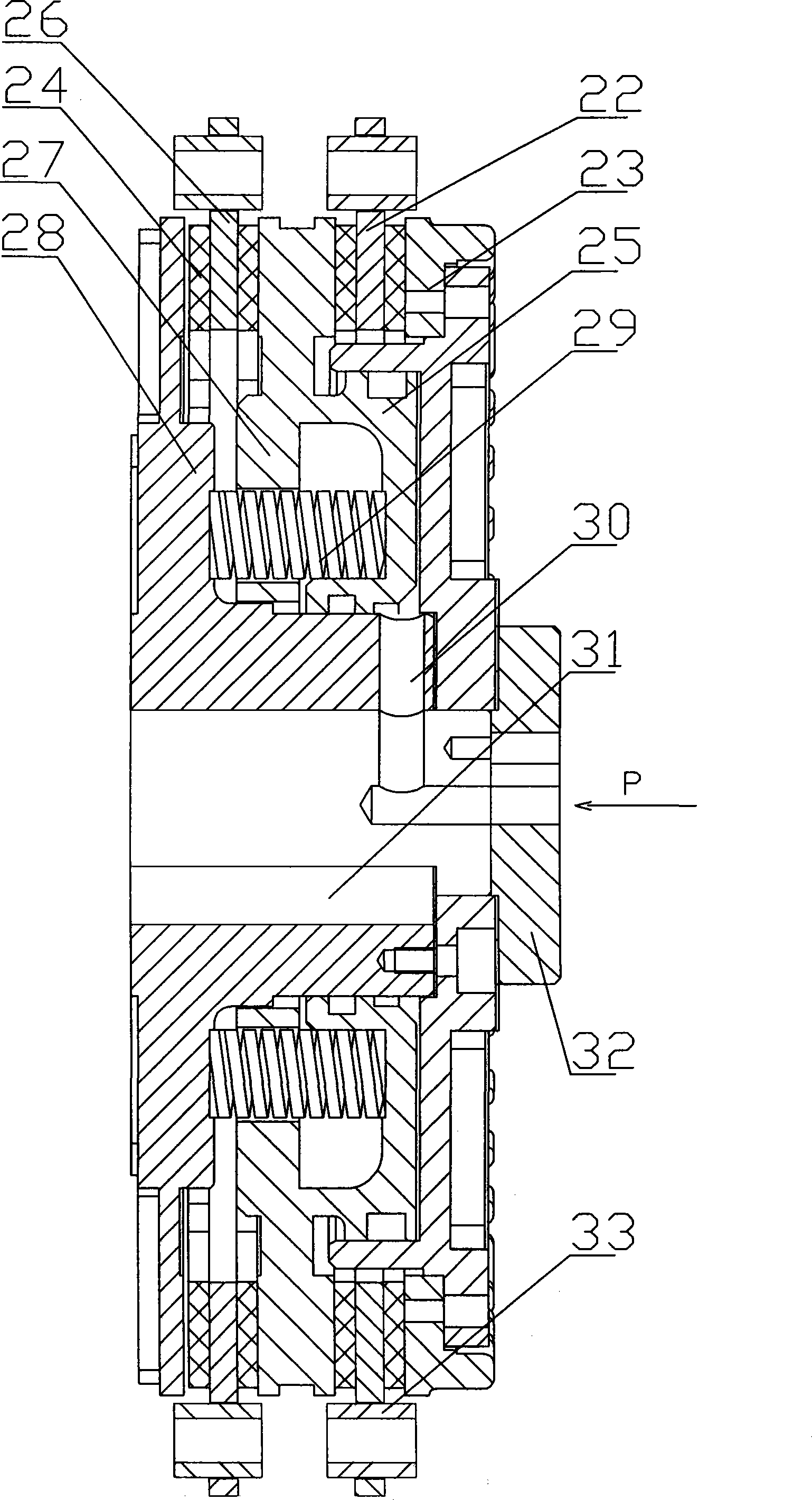

[0014] In the middle of the crankshaft 16 rear end, there is a vertically and horizontally connected blind hole for the air inlet P to be connected with the gas source.

[0015] There is an air inlet 30 on the surface of one side of the body 28 to communicate with the air inlet P, and the body is slippery matched with the piston 27 with a uniformly distributed spring 29. The blind holes on the body and the piston cooperate, the two side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com