Manufacture method of ship rudder horn

A manufacturing method and rudder arm technology, applied in the manufacturing field, can solve the problems of difficulty in controlling the dimensional accuracy, the tendency of cracks and shrinkage to increase, and the difficulty in formulating casting processes with large disparities in length, weight and wall thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

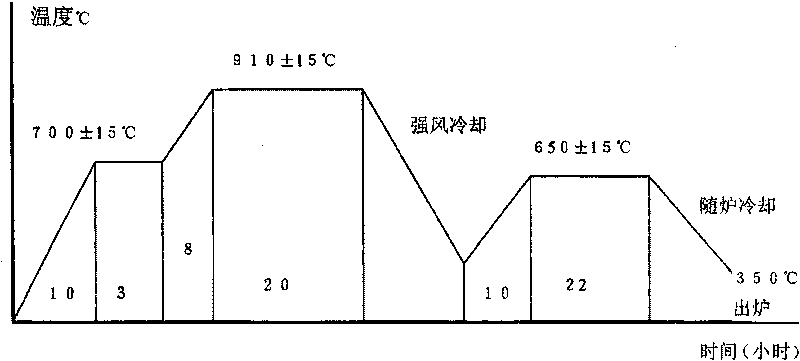

Embodiment 1

[0028] The rudder arm castings used by foreign classification societies through practice have a weight of 56.8 tons and a total length of 6.3 meters. The technical quality requirements are as follows:

[0029] 1) Chemical composition

[0030] C≤0.23%, Si≤0.60%, Mn=1.20 to 1.60%, P≤0.035%, S≤0.035%,

[0031] Cr≤0.30%, Mo≤0.08%, Cu≤0.3%, V≤0.03%, Al=0.015-0.08%,

[0032] (N%xAlacidsol%)x10 5 ≤60.

[0033] 2) Mechanical properties

[0034] Rm≥520Mpa, Rp0.2≥260Mpa, A4≥20%, Z≥25%, Kv≥27J (0℃).

[0035] 3) The magnetic particle non-destructive testing and ultrasonic non-destructive testing of the surface and internal quality of the casting meet the requirements of ship inspection. To this end, a detailed production plan was developed.

[0036] 1. Melting process

[0037] A. Melting stage: Put the return material (return material is the riser, gate, etc. of similar castings) 35%; steel scrap 15%; pig iron 10%; scrap steel and 2% lime are put into the electric furnace to be energized and melted wh...

Embodiment 2

[0052] Example 2: Through practice, the rudder arm castings of foreign classification societies that have been applied to have a weight of 65 tons and a total length of 7.5 meters, the technical quality requirements are as follows:

[0053] 1) Chemical composition

[0054] C≤0.23%, Si ≤0.60%, Mn=1.20 to 1.60%, P≤0.035%, S≤0.035%,

[0055] Cr ≤0.30%, Mo≤0.08%, Cu≤0.3%, V≤0.03%, Ai=0.015-0.08%,

[0056] (N%xAlacidsol%)x10 5 ≤60.

[0057] 2) Mechanical properties

[0058] Rm≥520Mpa, Rp0.2≥260Mpa, A4≥20%, Z≥25%, Kv≥27J (0℃).

[0059] 3) The magnetic particle non-destructive testing and ultrasonic non-destructive testing of the surface and internal quality of the casting meet the requirements of ship inspection.

[0060] To this end, a detailed production plan was developed.

[0061] 1. Melting process

[0062] A. Melting stage: Put the return material (return material is the riser, gate, etc. of similar castings) 40%; steel scrap 18%; pig iron 12%; scrap steel balance and 1.5% lime into the elec...

Embodiment 3

[0078] Example 3: The rudder arm castings of foreign classification societies that have been applied through practice have a weight of 38.8 tons and a total length of 4.3 meters. The technical quality requirements are as follows:

[0079] 1) Chemical composition

[0080] C≤0.23%, Si≤0.60%, Mn=1.20 to 1.60%, P≤0.035%, S≤0.035%,

[0081] Cr≤0.30%, Mo≤0.08%, Cu≤0.3%, V≤0.03%, Al=0.015-0.08%,

[0082] (N%xAlacidsol%)x10 5 ≤60.

[0083] 2) Mechanical properties

[0084] Rm≥520Mpa, Rp0.2≥260Mpa, A4≥20%, Z≥25%, Kv≥27J (0℃).

[0085] 3) The magnetic particle non-destructive testing and ultrasonic non-destructive testing of the surface and internal quality of the casting meet the requirements of ship inspection.

[0086] To this end, a detailed production plan was developed.

[0087] 1. Melting process

[0088] A. Melting stage: 30% of the return material (return material is the riser, gate, etc. of similar castings); 16% of steel cut; 14% of pig iron; the balance of scrap steel and 1.8% of lime are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com