Grinding method combining mechanical reciprocation and supersonic vibration

A technology of ultrasonic vibration and grinding method, which can be used in ultra-finishing machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low grinding efficiency, ensure flatness and smoothness, expand the scope of use, improve grinding and polishing quality and effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

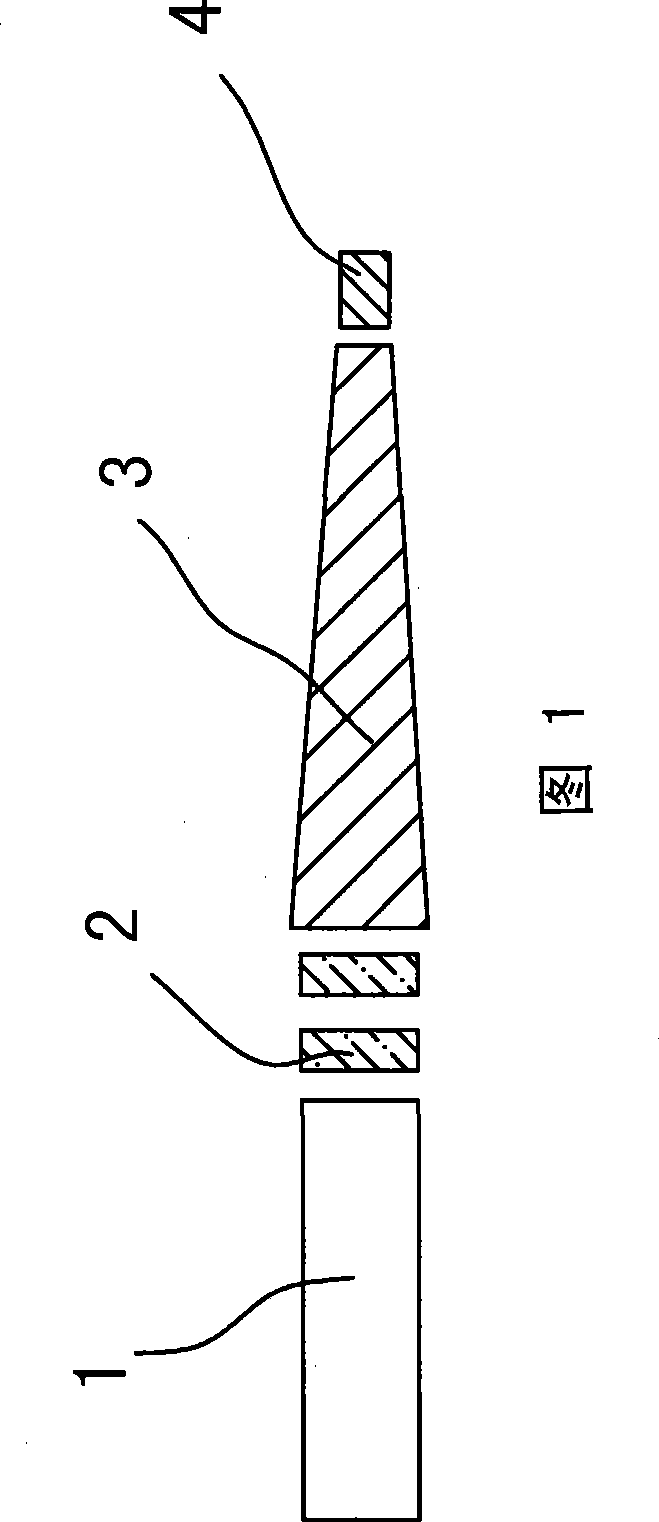

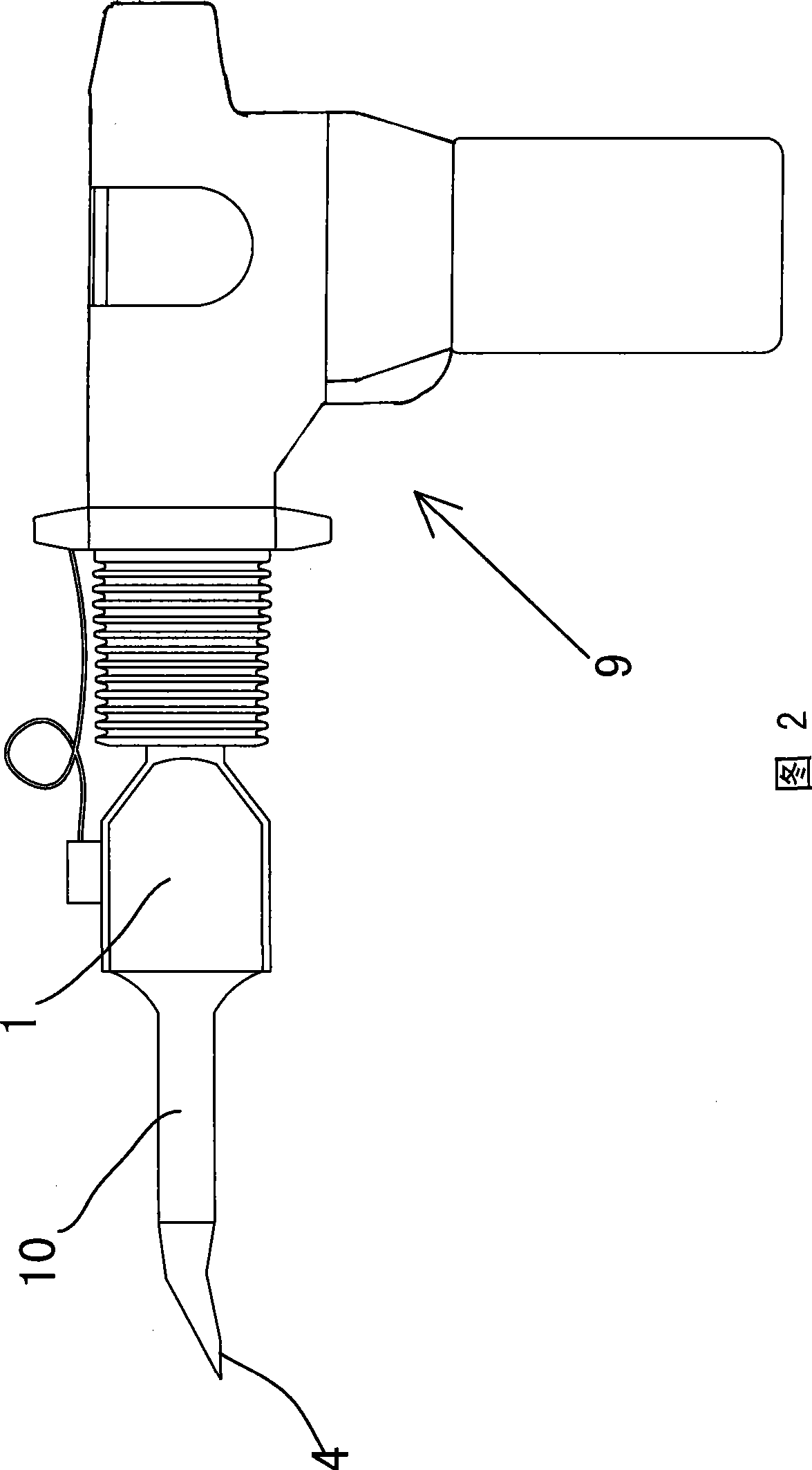

[0032] Such as image 3 As shown, a mechanical reciprocating and ultrasonic vibration compound grinding method includes at least two grinding processes, using grinding heads 4 with different hardness and abrasive materials 5 with different particle diameters between each grinding process, and the hardness of the grinding head 4 is from From hard to soft, the particle diameter of the abrasive 5 changes from large to small according to the order of the grinding process. In each grinding process, the same grinding head is driven to grind the surface of the workpiece by mechanical reciprocating vibration and superimposed ultrasonic vibration, as shown in Figure 2. As shown, an ultrasonic generating device is coaxially arranged on the main shaft (not shown) of the hand-held grinding and polishing machine 9, and acts on the same grinding head 4 to grind the workpiece surface 6 at the same time. Driven by the moving spindle, it performs reciprocating motion with a large amplitude; at ...

Embodiment 2

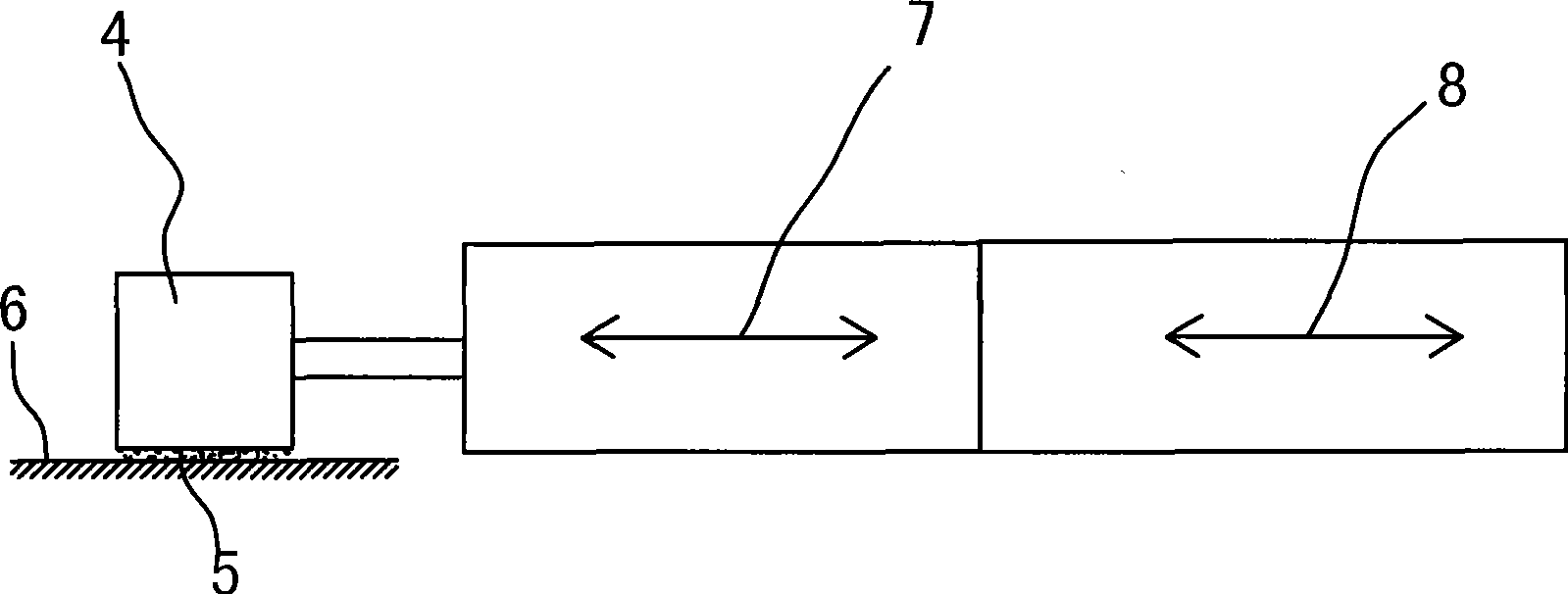

[0036] As shown in Figure 4, a mechanical reciprocating and ultrasonic vibration composite grinding method differs from Embodiment 1 in that the direction of mechanical reciprocating motion and the direction of ultrasonic vibration are superimposed at an acute angle in a plane parallel to the surface of the workpiece to be processed; in Figure 4 Arrow 4 and arrow 5 respectively represent the direction of ultrasonic vibration and mechanical reciprocating motion; others are the same as in Embodiment 1, and will not be described in detail here. In addition, the manner in which the direction of mechanical reciprocating motion and the direction of ultrasonic vibration are superimposed at an obtuse angle is the same, and will not be described in detail here.

Embodiment 3

[0038] As shown in Figure 5, a mechanical reciprocating and ultrasonic vibration composite grinding method includes at least two grinding processes. The difference from Embodiment 1 is that the direction of mechanical reciprocating motion and the direction of ultrasonic vibration are in a plane parallel to the surface of the processed workpiece. They are stacked at right angles; arrows 4 and 5 in Figure 5 represent directions of ultrasonic vibration and mechanical reciprocating motion respectively; others are the same as in Embodiment 1 and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com