Closed type condensate water recovery device

A technology for recycling device and condensate water, which is applied in supplementary water supply, preheating, steam generation, etc., can solve the problems of less than 60% energy utilization rate, increased recycling cost, loss of water quality conditions, etc., to improve energy utilization rate, increase The effect of steam production and shortening of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

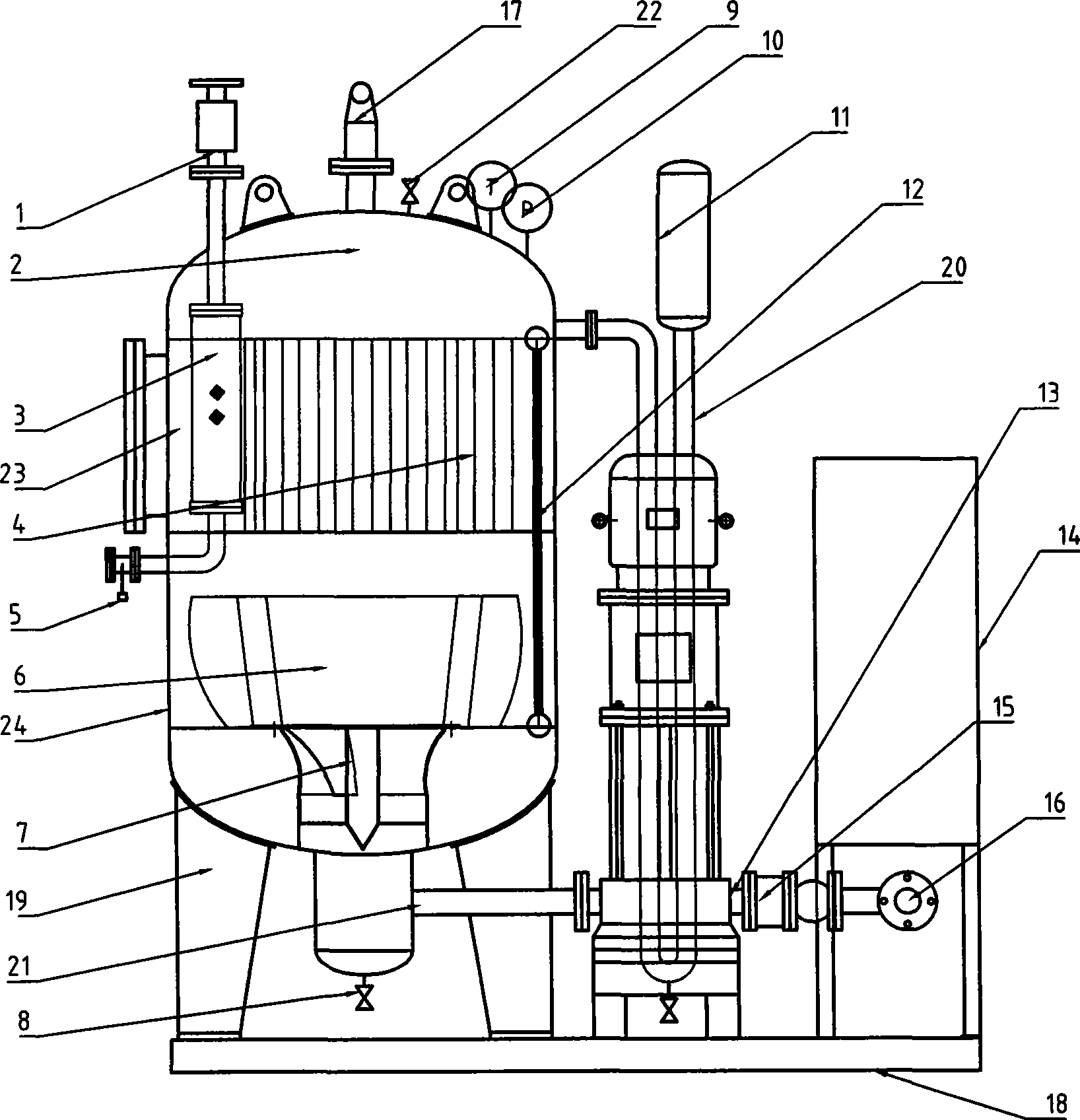

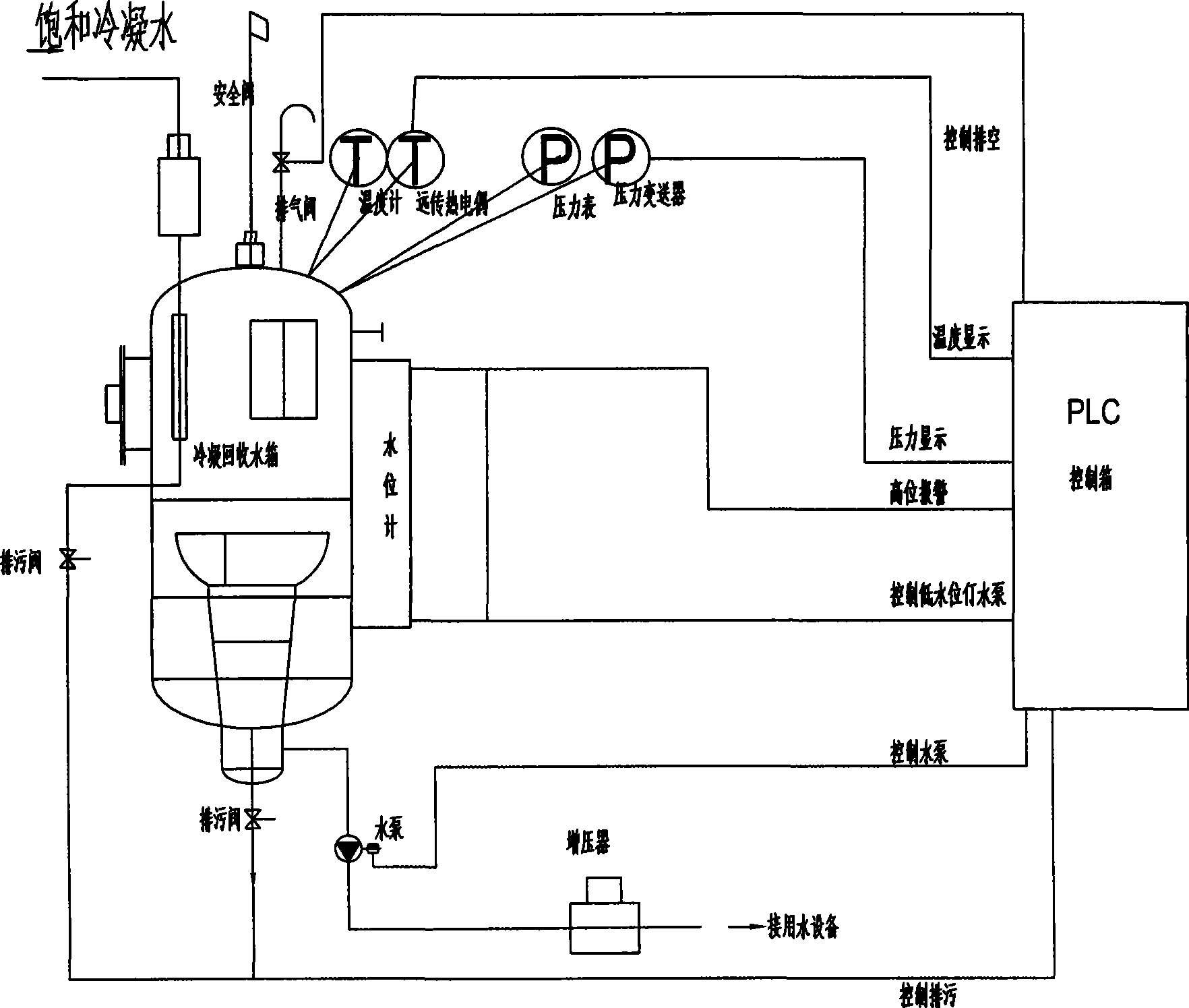

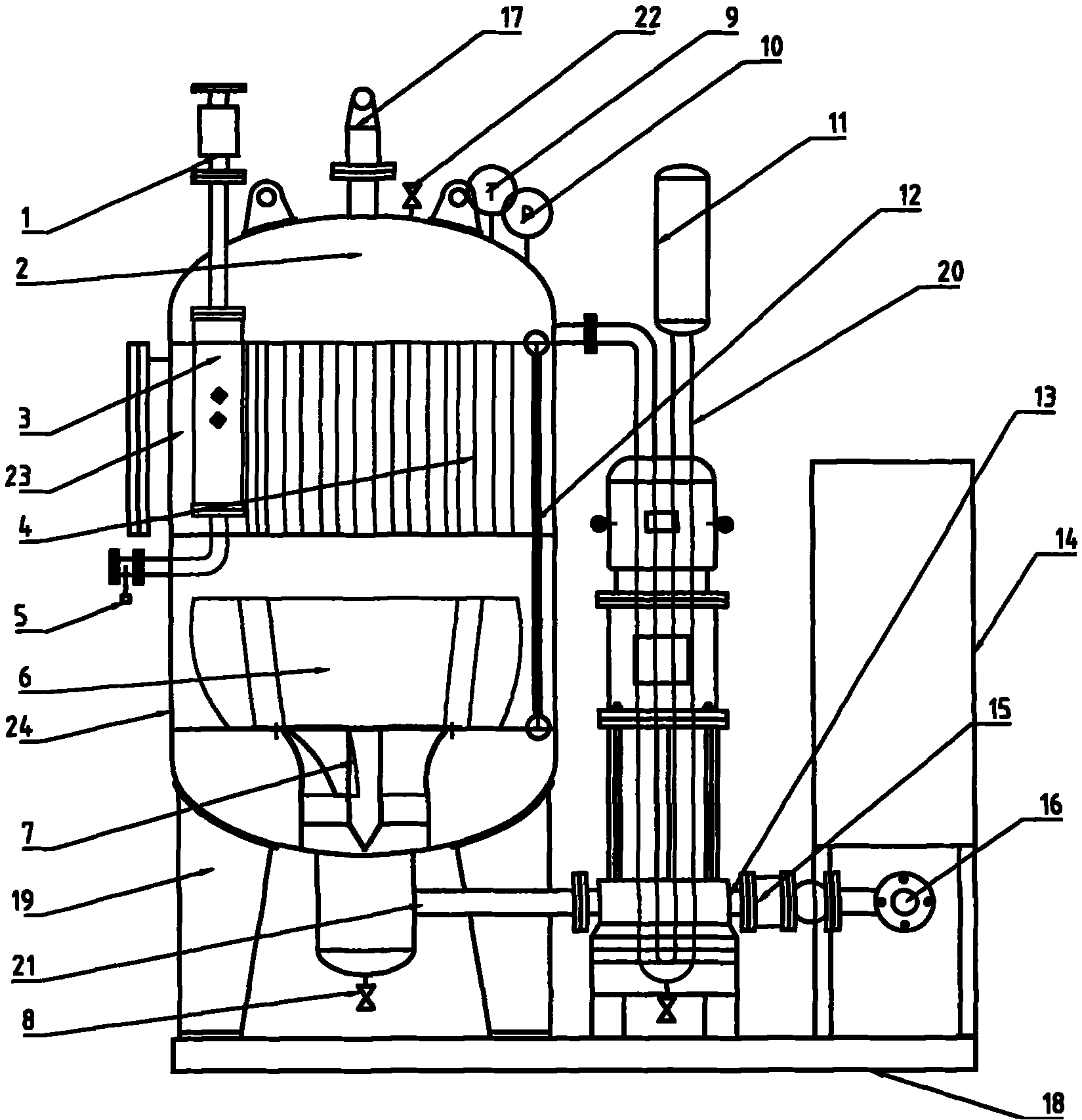

[0008] The present invention will be further described below in conjunction with the accompanying drawings to give 1 embodiment. like figure 1 Shown, the present invention is made of centralized steam trap (1), strainer (3), circular steam-water separator (4), decontamination valve (5), deflector (6), cavitation elimination device (7), Drain valve (8), thermometer (9), pressure gauge (10), pressure balancer (11), water level gauge (12), high pressure water pump (13), PLC control box (14), supercharger (15), Water outlet (16), safety valve (17), machine base (18), water tank foot (19), U-shaped pipe (20), high-pressure water pump pipe (21), exhaust valve (22), deflector (23 ), water tank shell (24) and centralized steam trap pipeline (25). During processing, first purchase or process the above-mentioned parts, wherein, the decontamination valve (5), the drain valve (8), the exhaust valve (22), the cavitation elimination device (7) and the sensor are made of stainless steel; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com