Shell-pipe head exchanger by double helix flowing of fluid medium in or out of heat exchange tube

A shell-and-tube heat exchanger and fluid medium technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed tubular conduit assemblies, etc., can solve the problem of reducing the mass flow rate of the effective transverse tube bundle and reducing the heat transfer on the shell side Efficiency, shortening the life of the heat exchanger, etc., to achieve the effect of reducing scaling, reducing flow resistance and scaling, and enhancing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

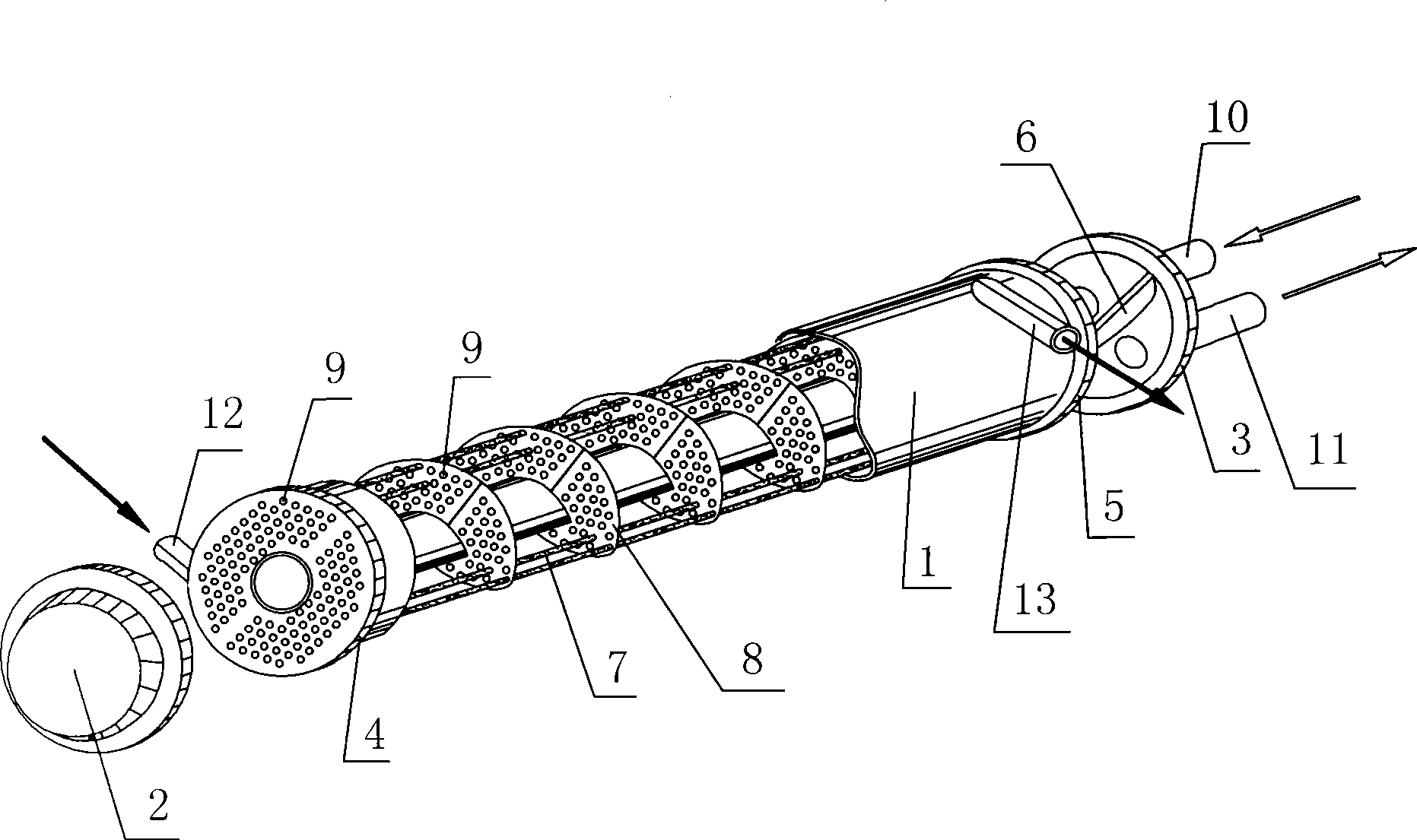

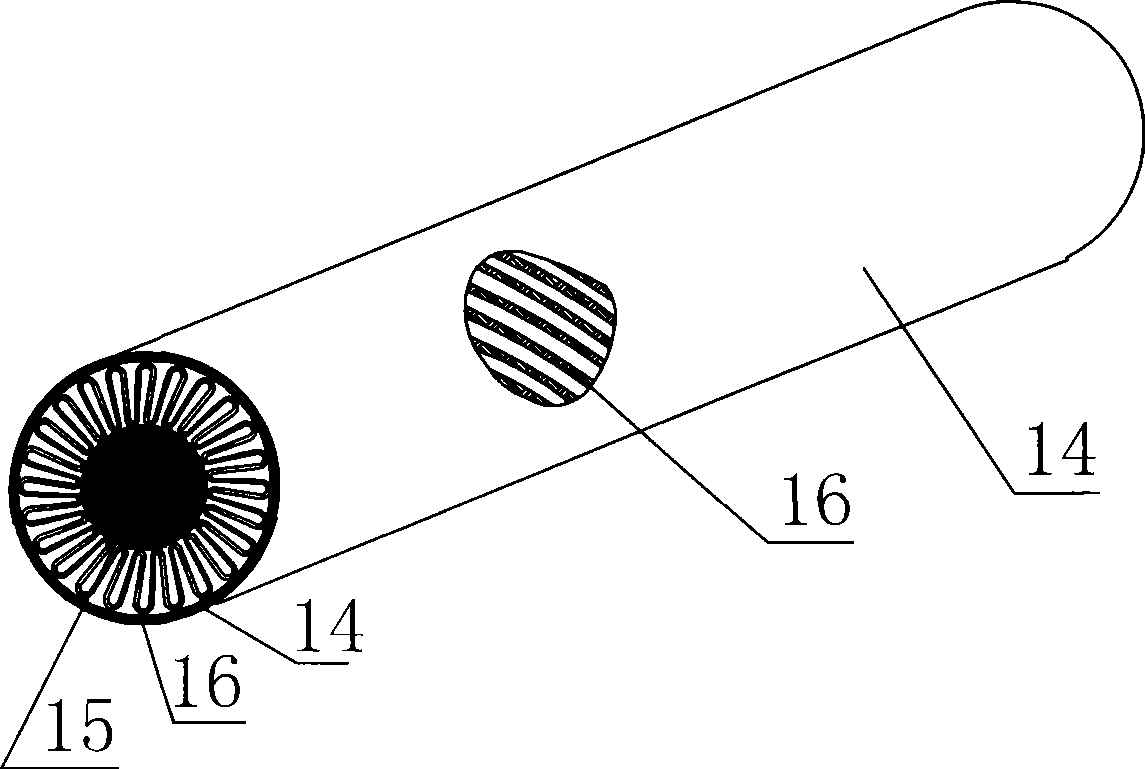

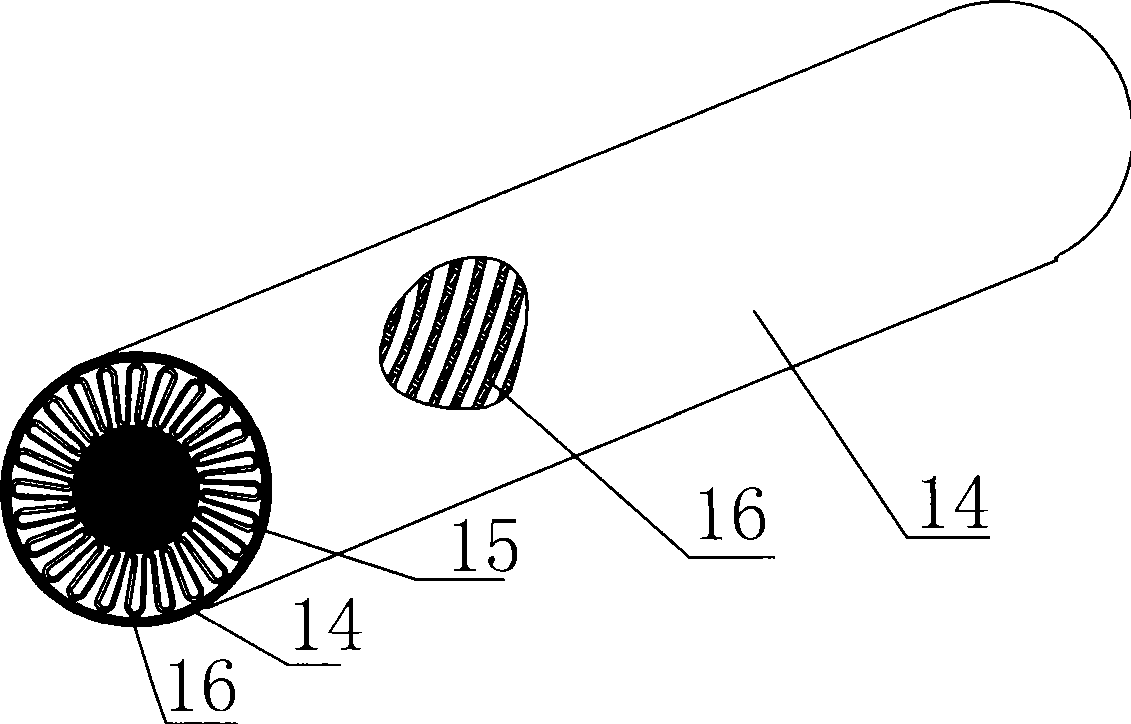

[0033] Such as figure 1 As shown, the present invention consists of a shell 1 sealed by two ends of the head, that is, the left head 2 and the right head 3, the shell side inlet 12 and the shell side outlet 13 arranged on the side wall of the shell 1, respectively located in the shell The first sealing plate 4 and the second sealing plate 5 at the two ends of the body 1, a group of tube-side inlets 10 and tube-side outlets 11 that are all arranged on the right head 3, baffles arranged inside the shell 1, and multiple parallel It consists of heat exchange tubes 7 installed between the first sealing plate 4 and the second sealing plate 5. Wherein, the shell side inlet 12 and the shell side outlet 13 are respectively located at two ends of the side wall of the housing 1 . The first sealing plate 4 and the second sealing plate 5 are correspondingly provided with a plurality of through holes 9 through which the heat exchange tubes 7 pass, and the outer walls of the heat exchange t...

Embodiment 2

[0041] Such as Figure 5 As shown, in this embodiment, the number of the tube pass inlet 10 and the tube pass outlet 11 is a group, and the tube pass inlet 10 and the tube pass outlet 11 are respectively located on the two heads at the left and right ends of the housing 1, specifically The tube side inlet 10 is located on the right head 3, the tube side outlet 11 is located on the left head 2, and there is no partition 6 between the sealing plate 2 5 and the right head 3, so that the longitudinal spiral flow channel It communicates with the tube-side inlet 10 and the tube-side outlet 11 to form a right-to-left helical one-way flow channel in the tube; the structure, connection relationship and function of the rest of the parts are the same as those in Embodiment 1. That is to say, the difference between this embodiment and Embodiment 1 is that: the tube-side inlet 10 and the tube-side outlet 11 are respectively located on the two heads, and the two form a unidirectional flow c...

Embodiment 3

[0044] Such as Figure 6 As shown, in this embodiment, two heat exchangers are connected in series, and the heat exchange fluid flows in from the shell-side inlet 12 of one of the heat exchangers, passes through the shell-side circulation channel formed by the spiral baffle 8, and flows The shell side outlet 13 of this heat exchanger flows out; at the same time, the shell side outlet 13 of this heat exchanger communicates with the shell side inlet 12 of another heat exchanger, so the heat exchange fluid flows from the shell side of another heat exchanger The inlet 12 flows in, also passes through the shell-side flow channel, and then flows out from the shell-side outlet 13, thus forming a back-and-forth double-shell-side flow channel. Specifically: the shell-side inlet 12 of the previous heat exchanger is located on the left side of the shell 1, and its shell-side outlet 13 is located on the right side of the shell 1; correspondingly, the shell-side inlet 12 of the next heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com