Coating material for coal, modified coal, process for the production of coating material for coal, and process for production of modified coal

A manufacturing method and coating agent technology, which is applied in the petroleum industry, solid fuel, coke oven, etc., can solve the problems of coal not necessarily softening and melting characteristics, achieve homogeneity and stable quality, suppress the reduction of calorific value, and realize long-term Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

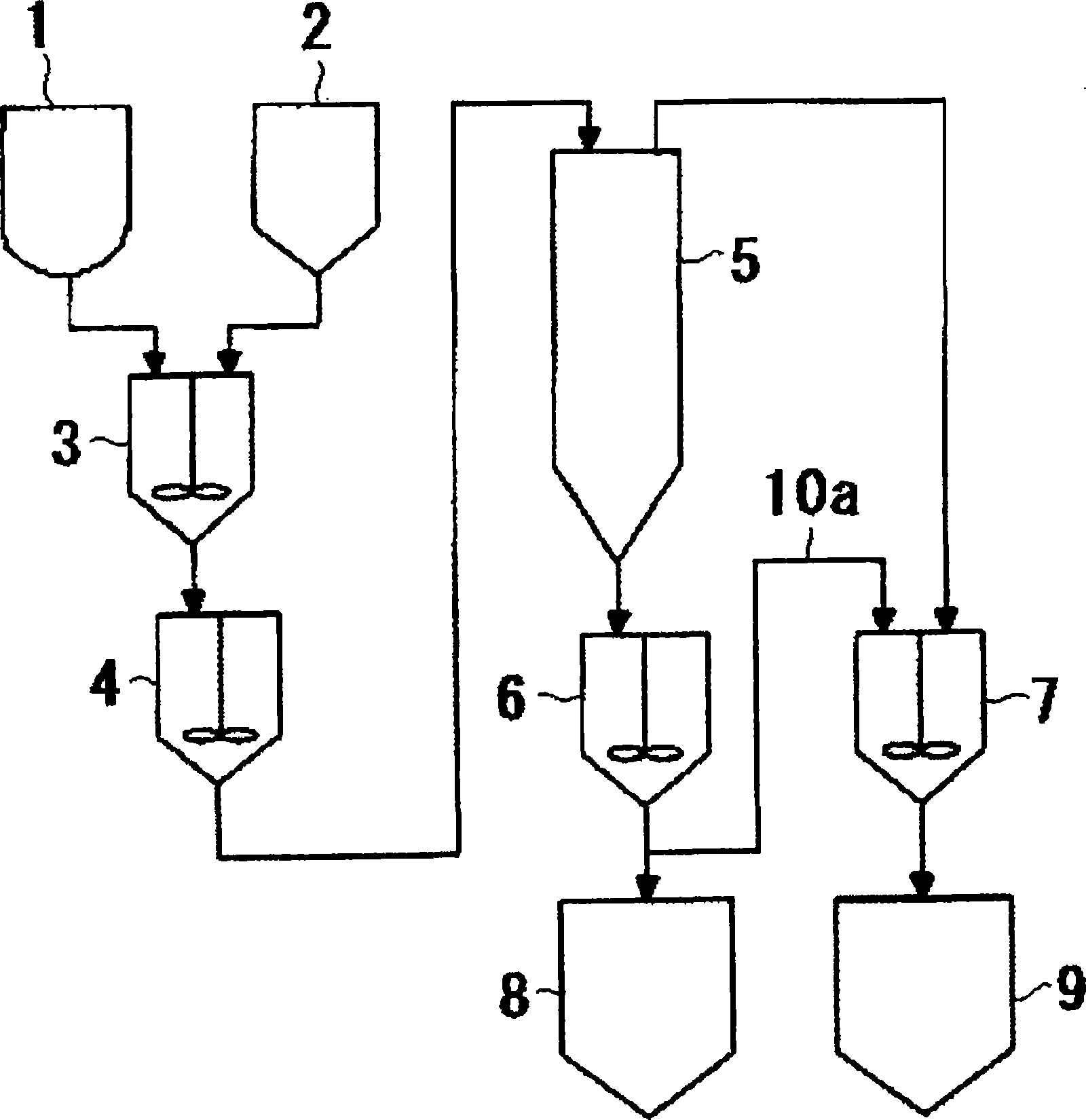

[0070] [Preparation of coating agent]

[0071] Coal A (lignite) with a water content of 30% by weight and methylnaphthalene were mixed, and extracted using a pressure vessel at a temperature of 360° C., a pressure of 2 MPa, and a time of 1 hour. After the extraction, an extract (a mixed solution of a coating agent and methylnaphthalene) is collected by solid-liquid separation, and methylnaphthalene is distilled off from the extract to obtain coal B (corresponding to the coating agent) as extracted carbon.

[0072] [the coating to coal]

[0073] Coal A and 5% by weight, 10% by weight, 12% by weight, or 20% by weight of coal A of coal B were stirred and mixed with methylnaphthalene at 360° C. to obtain a slurry. Methylnaphthalene was removed from the slurry by distillation to obtain coal A coated with coal B as an upgraded coal.

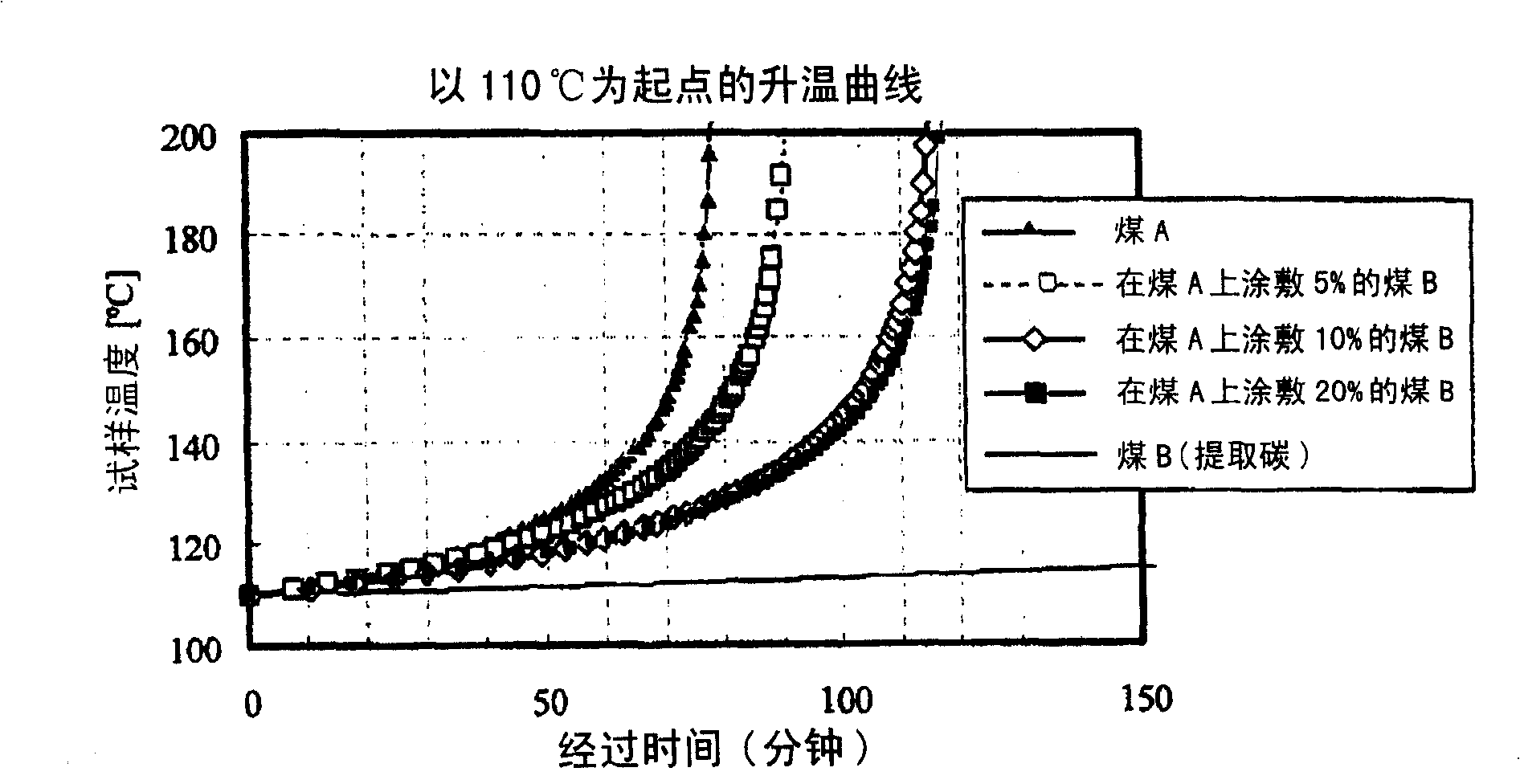

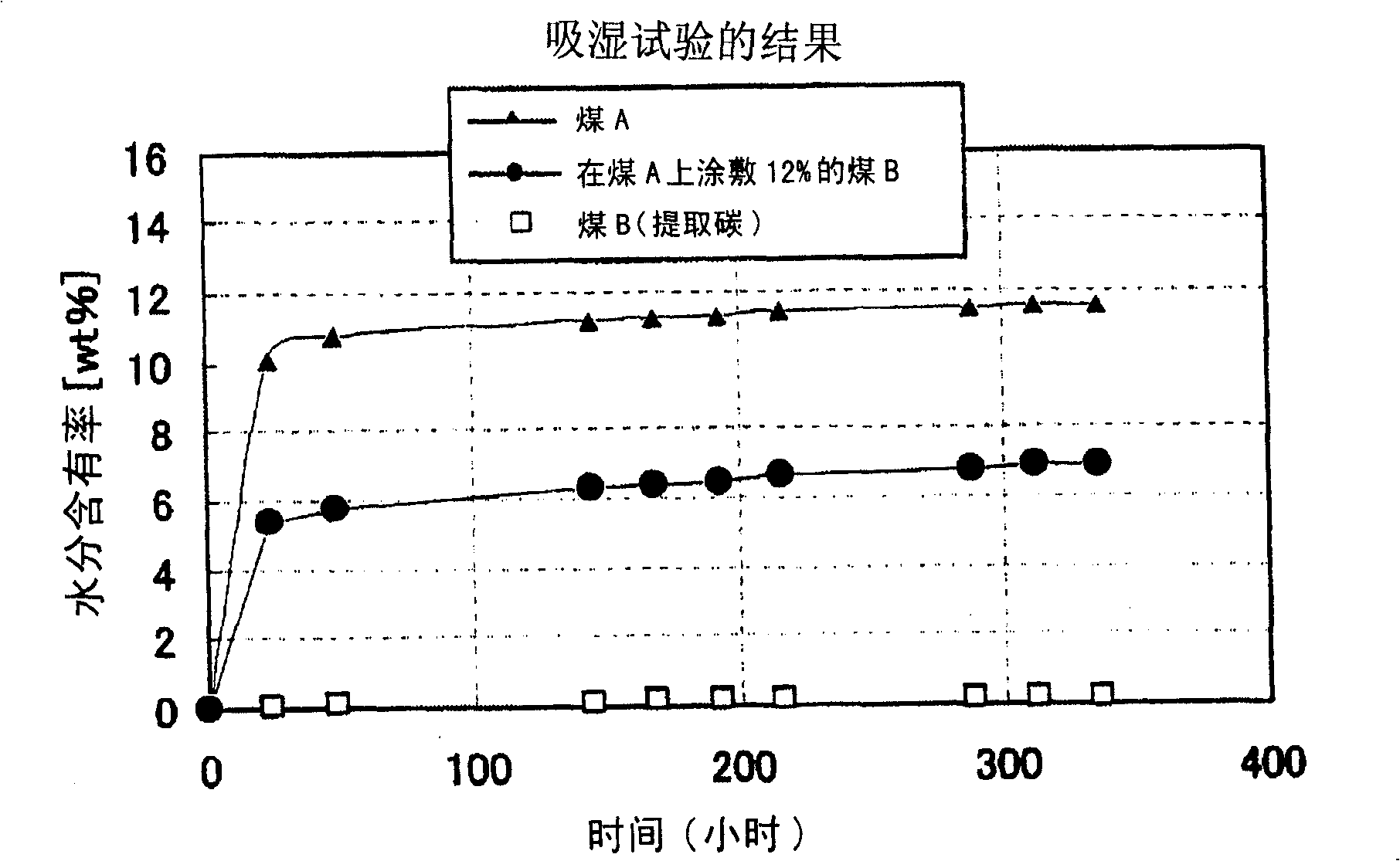

[0074] In order to investigate the pyrophoric property and hygroscopicity of coal A coated with coal B obtained by the above method, the following o...

Embodiment 2-7

[0082] The extraction solvent (methylnaphthalene) and pulverized bituminous coal (coal C) or lignite (coal D) were prepared into a slurry-like mixture in a weight ratio of 80:20. Next, the slurry-like mixture was subjected to extraction treatment for 1 hour under the conditions of a temperature of 370° C. and a pressure of 2 MPa. Then, a gravity settling tank is used, the extract liquid is taken out from the upper part of the settling tank, and the slurry-like mixture composed of the extract liquid and the extraction residue is taken out from the lower part. Thereafter, the mixture was prepared by changing the ratio of the extract taken out from the upper part of the gravity settling tank and the slurry-like mixture taken out from the lower part. Next, the extraction solvent is removed by evaporative drying to obtain coal.

[0083] The softening and melting properties were evaluated using industrial analysis values (measured according to JIS M 8812) and Gisler plastometer m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com