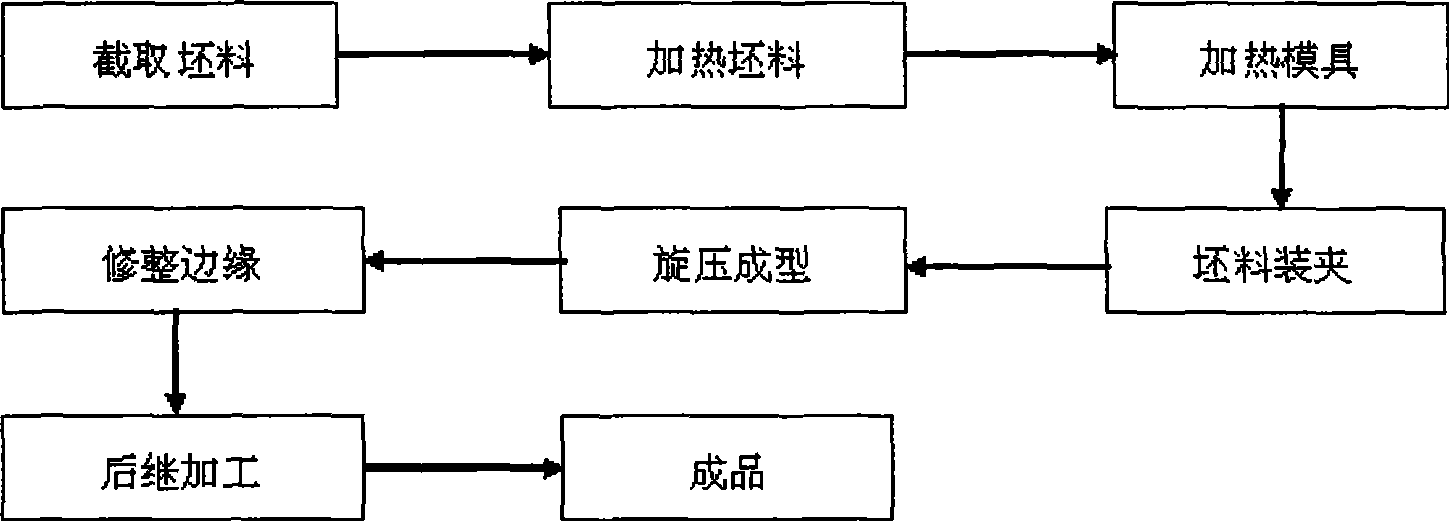

Magnesium alloy sheet material flow forming and molding process

A spinning forming and magnesium alloy technology, applied in the field of metal materials, can solve the problems of increased operational skill requirements, increased production costs, and short action time, achieving high production efficiency, improved production efficiency, and less heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0047] 1. Intercept a magnesium alloy blank 1: The magnesium alloy blank 1 is a deformed magnesium alloy sheet AZ31B, with a thickness of 3.5mm. According to the shape, size and thickness of the molded product, after accurate calculation, the volume of the magnesium alloy blank 1 can be known. quantity.

[0048] 2. Heating the magnesium alloy billet 1: Put the magnesium alloy billet 1 into the heating constant temperature furnace, set the temperature to 310±10°C, and keep the holding time for 60 minutes. It is to homogenize the temperature of the material.

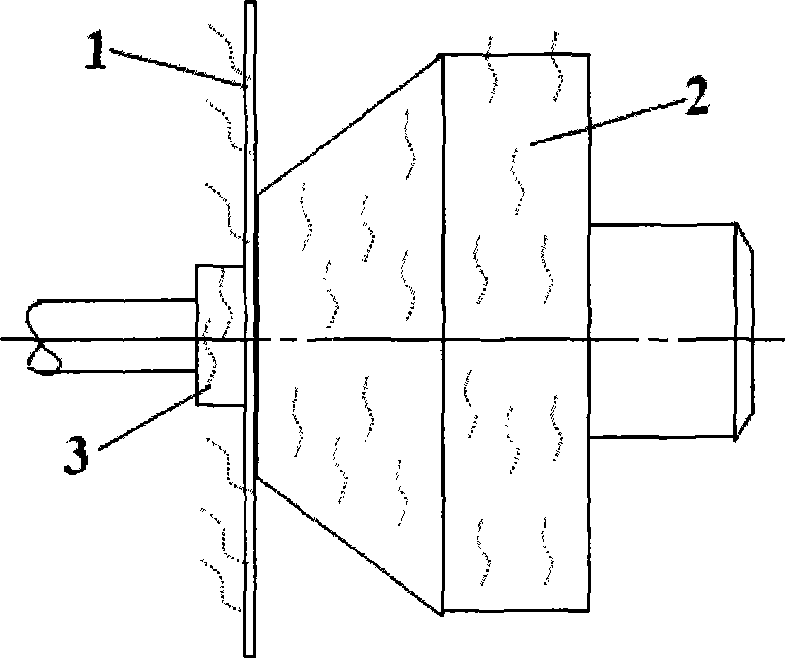

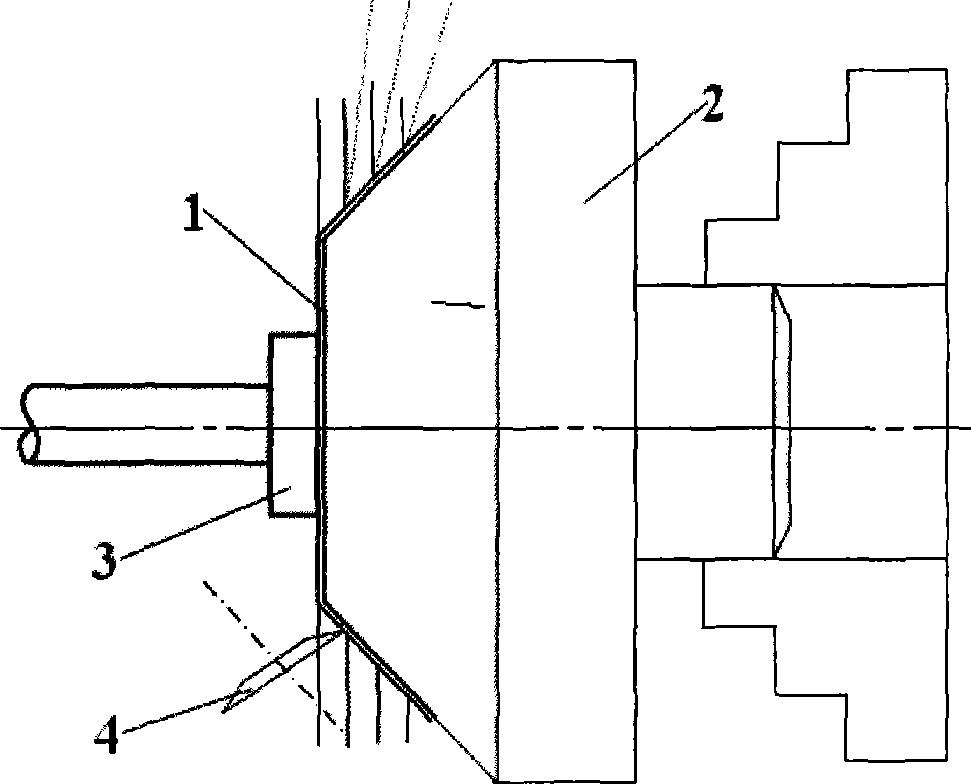

[0049] 3. Heating the spinning mold 2: Spinning the mold 2 and the top block 3 with an oxygen-acetylene flame, and the temperature is between 240 and 280 °C.

[0050] 4. Clamping of magnesium alloy billet 1: Quickly place the heated magnesium alloy billet 1 on the spinning die 2 to ensure the correct clamping position, and quickly move the top block 3 to clamp the magnesium alloy billet 1. The magnesium alloy billet 1 is ...

specific Embodiment approach 2

[0056] 1. Cut out a magnesium alloy blank 1: The magnesium alloy blank 1 is a deformed magnesium alloy sheet AZ61A with a thickness of 3.5mm. According to the shape, size and thickness of the molded product, after accurate calculation, the volume.

[0057] 2. Heating the magnesium alloy billet 1: Put the magnesium alloy billet 1 into the heating constant temperature furnace, set the temperature to 380±10°C, and keep the holding time for 35 minutes. It is to homogenize the temperature of the material.

[0058] 3. Heating the spinning mold 2: use an oxygen-acetylene flame to heat the spinning mold 2 and the top block 3, and the temperature is between 240 and 280 °C.

[0059] 4. Clamping of blank 1: Quickly place the heated magnesium alloy blank 1 on the spinning die 2 to ensure the correct clamping position, and quickly move the top block 3 to clamp the magnesium alloy blank 1, and the magnesium alloy blank 1 is spun The mold 2 and the top block 3 are clamped and fixed.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com