A kind of high impact toughness titanium alloy and the method for using titanium alloy to prepare seamless pipe

A technology of seamless pipes and titanium alloys, applied in metal rolling, metal processing equipment, manufacturing tools, etc., can solve the problems of high room temperature deformation resistance, slow application of titanium alloy tubing, etc., without affecting impact toughness and elongation. , Solve the problem of galvanic corrosion and enhance the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

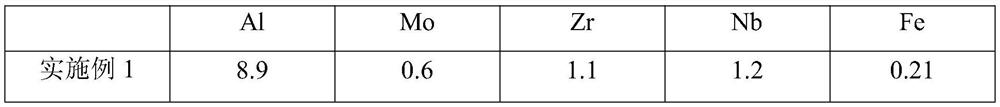

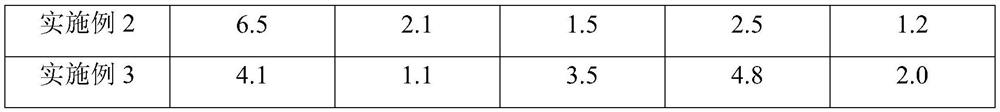

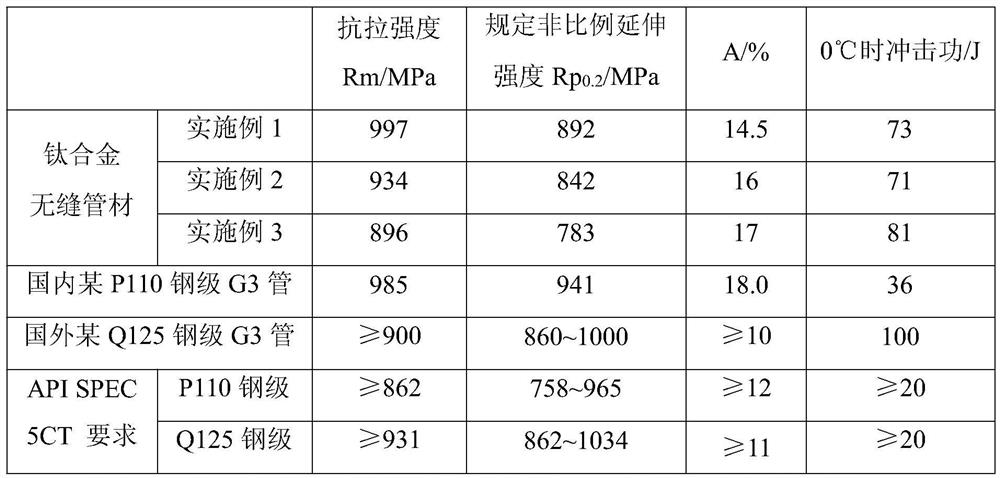

Embodiment 1

[0038] Step 1, ingot preparation: 铌 中 合, MO block, pure sponge Zr, nail nails, sponge Ti by mixing, pressed electrode, vacuum self-consuming twice smelting Alloy ingots, alloy phase vary from 973 ° C.

[0039] Step 2, the billet preparation: 1150 ° C Seduch forging, 3-4 fire, 960 ° C, two fire, rehabilitation, rendering, φ600 bar blank.

[0040]Step three, oblique rolling perforation: After heating the rod to 950 ° C, the holding time was 420 min, then the shocked rolling perforation was carried out, and the billet of φ630 was prepared.

[0041] Step 4, hot rolling and fixed diameter: heat rolling after the diaphragm inversion, hot rolling, spraying boron sand inside the tube as a lubricant, and the deformation amount is controlled at 50-70%. Then be reduced diameter, and the extraction ratio is 20-30% during the reduction ratio, the thickness thickening is about 10% of the wall thickness of the heat rolling, and the maximum length of φ508 × 21 is prepared. Can reach 10m.

[0042...

Embodiment 2

[0045] Step 1, ingot preparation: 铌 中 合, MO block, pure sponge Zr, nail nails, sponge Ti by mixing, pressed electrode, vacuum self-consuming twice smelting Alloy ingots, alloy phase vary from 988 ° C.

[0046] Step 2, the billet was prepared: 1150 ° C Seduch forging, 3-4 fires, 960 ° C, two fire, rehabilitation, rendering, φ350 bar blank.

[0047] Step three, oblique rolling perforation: After heating the rod to 1000 ° C, the holding time is 200 min, then the oblique rolling perforation, the billet of φ360 is prepared.

[0048] Step 4, hot rolling and fixed diameter: heat rolling after the diaphragm in the punch, spraying borax in the pipe inside the tube, and the amount of deformation is controlled at 50-70%. Then, the diameter is reduced, and the extraction ratio is 20-30%, the reduction ratio is 20-30%, and the wall thickness thickens is about 10% of the wall thickness of the hot rolling, and the tube of φ219 × 12.7 can be prepared. More than 20m or more.

[0049] Step 5, heat...

Embodiment 3

[0052] Step 1, ingot preparation: 铌 中 合, MO block, pure sponge Zr, nail nails, sponge Ti by mixing, pressed electrode, vacuum self-consuming twice smelting Alloy ingots, alloy phase vary from 983 ° C.

[0053] Step 2, the billet preparation: 1150 ° C Seduch forging, 3-4 fire elsewed, 950 ° C two fire replacement rear processed φ350 bar blank.

[0054] Step three, oblique rolling perforation: The rod was heated to 1250 ° C for insulation, and the holding time was 90 min, then the tube blanks of φ159 were prepared by the oblique rolling perforation.

[0055] Step 4, hot rolling and fixed diameter: heat rolling after the diaphragm inversion, hot rolling, spraying boron sand inside the tube as a lubricant, and the deformation amount is controlled at 50-70%. Then be reduced diameter, and the extraction ratio is 20-30% during the reduction ratio, the thickness thickening is about 10% of the wall thickness of the heat rolling, and the maximum length of the tube of φ42 × 4.85 is prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com