Assembly line for composite shock-absorbing silencing piece and its industrial production method

A sound-absorbing sheet and production line technology, which is applied to brake parts, brake types, mechanical equipment, etc., to achieve the effects of low production cost, excellent shock-absorbing and sound-absorbing performance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

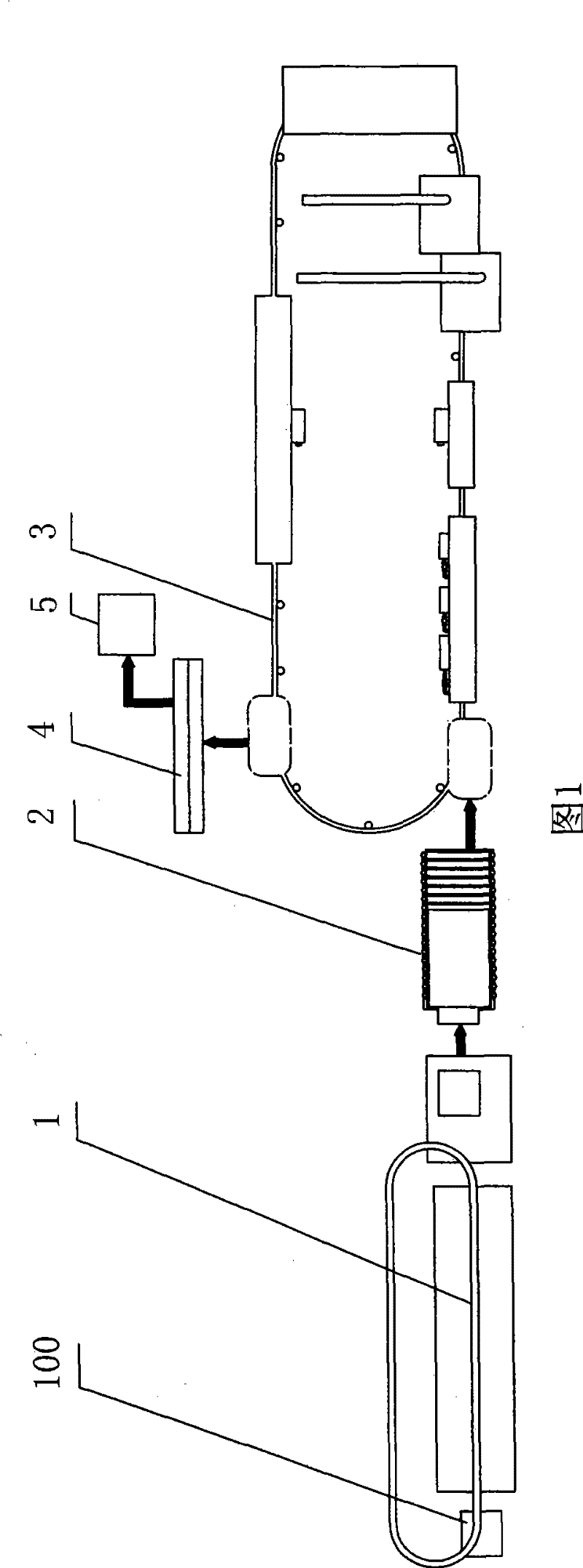

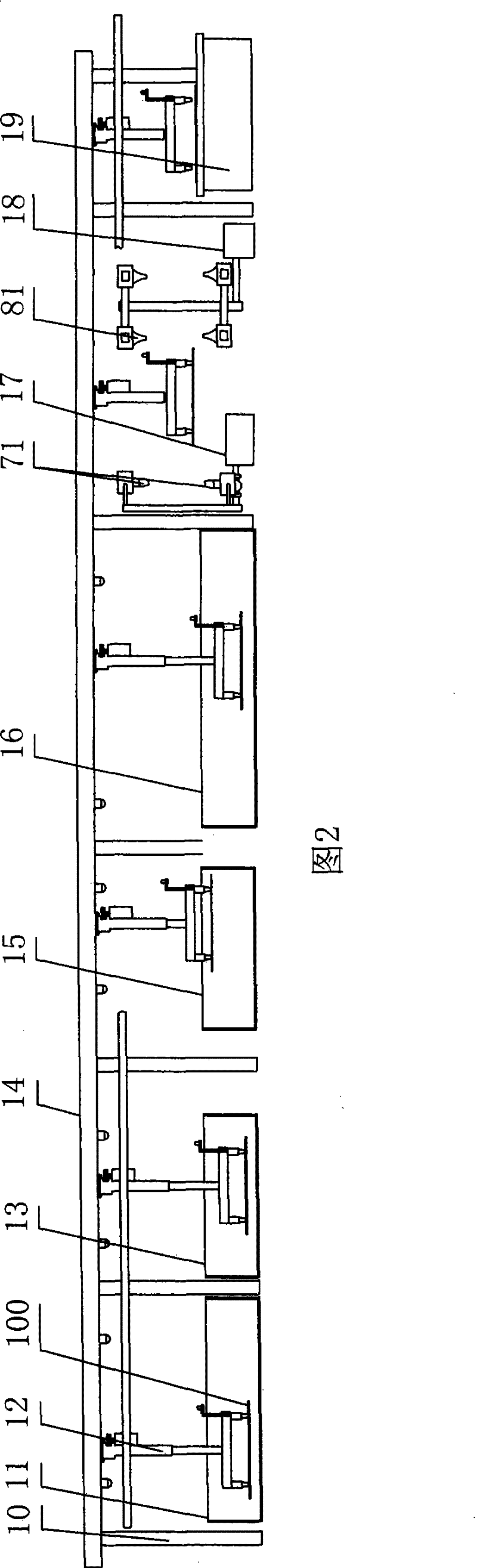

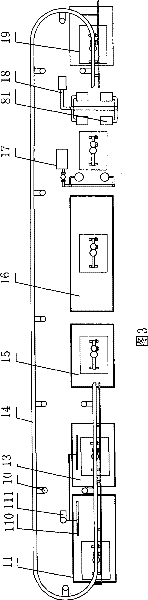

[0039] Fig. 1 is the structural representation of production line of the present invention. The production line consists of an automatic phosphating machine 1, an automatic compound machine 2, an automatic coating line 3, a shearing machine 4, and a punching machine 5 arranged on the level ground in sequence; each equipment is connected end to end and arranged in strict accordance with the above sequence . The thin iron plate 100 for making composite shock-absorbing and sound-absorbing sheets enters from the head end of the automatic phosphating machine, and then passes through the automatic phosphating machine for phosphating 1, the automatic compound machine 2 for compounding, the automatic coating line 3 for coating, and the shearing machine to cut the plate , Punch 4 blanking, and finally get a high-quality composite shock-absorbing sound-absorbing sheet.

[0040] Firstly, the iron plate 100 needs to go through the whole process of phosphating by the automatic phosphating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com