Method for marking wafer, method for marking poor product crystal grain, method for wafer contraposition, and wafer test machine

A wafer testing and wafer technology, which is used in semiconductor/solid-state device testing/measurement, laser welding equipment, electrical components, etc., and can solve problems such as difficulty in identification, difficult control of ink dot size, and easy contamination of wafers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention enumerates some embodiments in detail as follows, wherein the related icons are not drawn according to the actual style or proportion, and their function is only to facilitate the expression of the characteristics of the present invention, and for the sake of concise content, the same marked symbols in the description indicate that they have Components with the same function. In addition, the examples provided below are only for convenience of explaining the technical characteristics of the present invention, and the scope of the present invention is not limited by the provided examples, but is subject to the claims of the present invention.

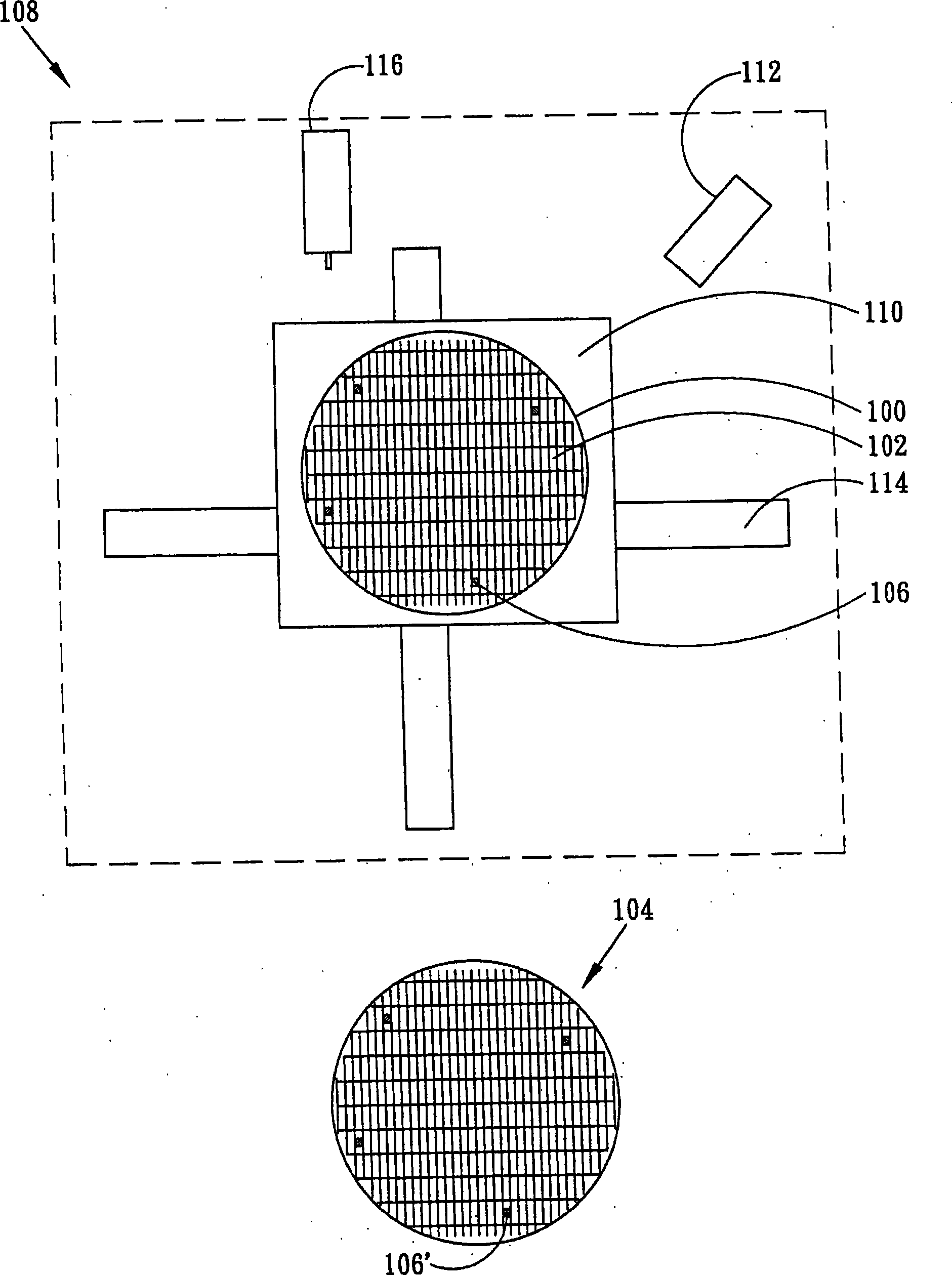

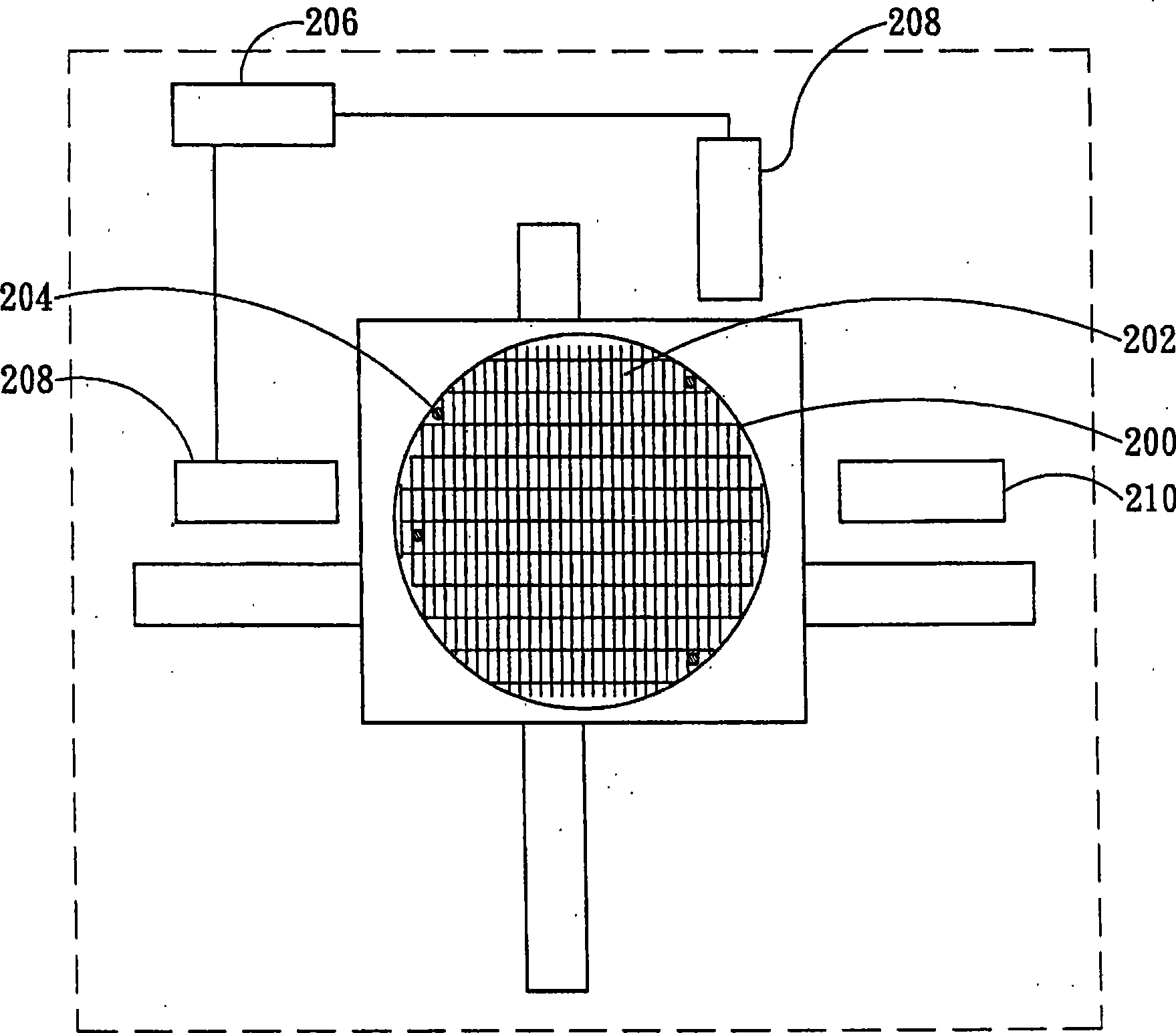

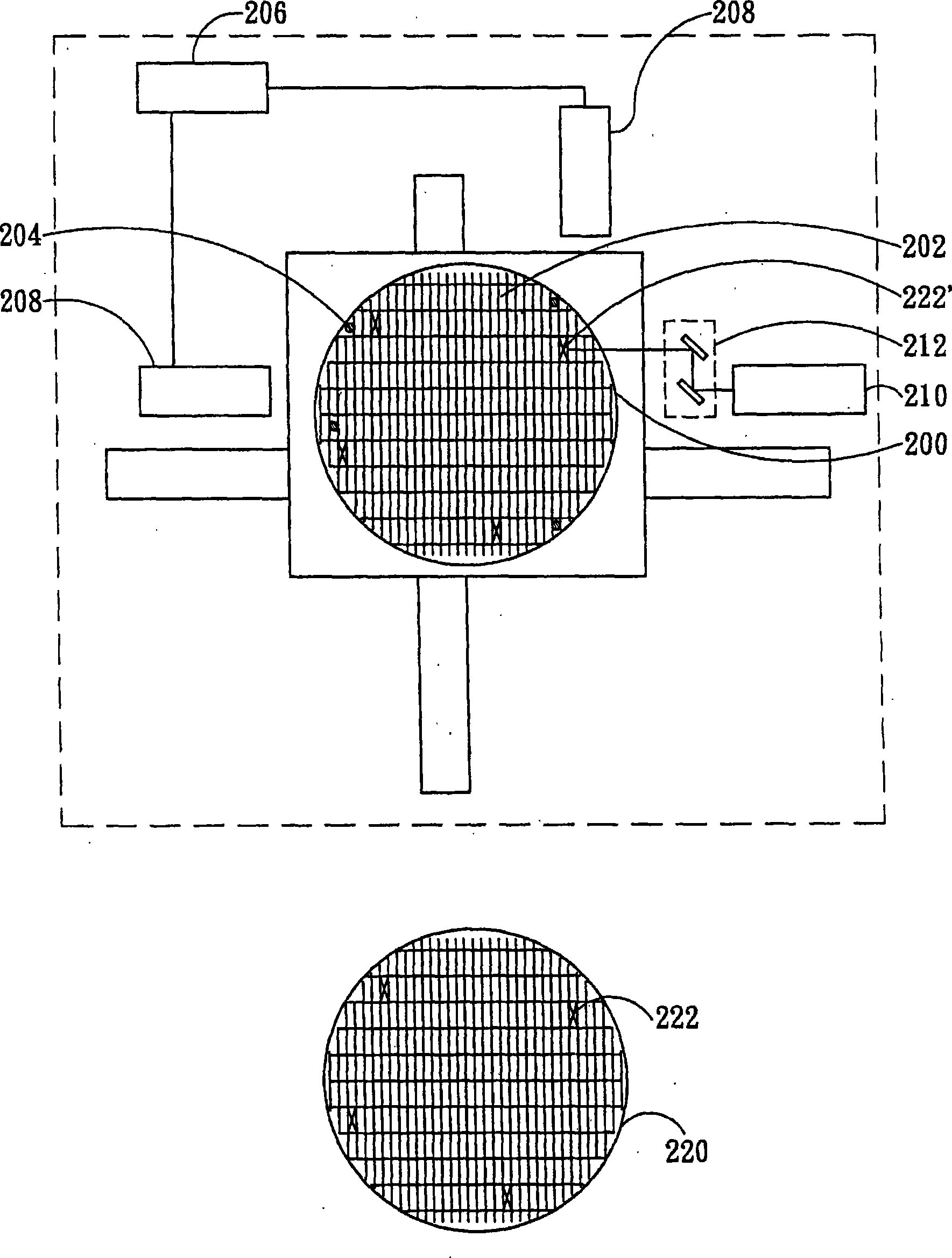

[0058] First, an embodiment of the present invention provides a wafer marking process, which uses lasers for wafer marking, and is combined with the wafer alignment method provided by the present invention to save the time for wafer alignment and improve wafer alignment. The accuracy of the circle alignment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com