Latexes bamboo charcoal stick fiber mattress and production method

A production method and technology of bamboo charcoal sticks are applied in the production of mattresses, spring mattresses, furniture covers and other directions, which can solve the problems such as the inability to replace the bamboo charcoal pads, affecting the comfort of the mattress, losing the efficacy of the bamboo charcoal, and reducing the weight. , Improve sleep performance, keep dry and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

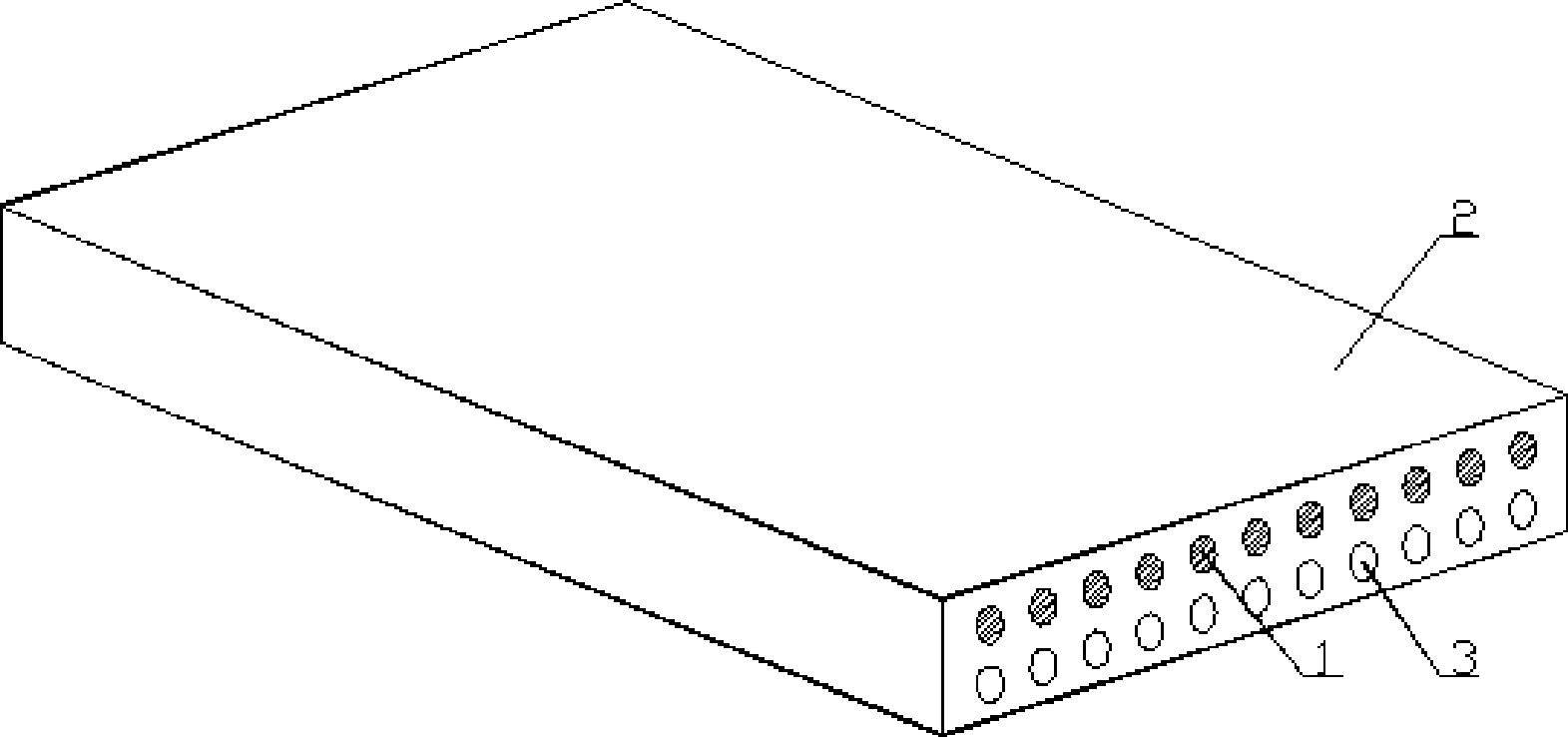

[0015] Embodiment 1 of the present invention: Bamboo charcoal particles are made into bamboo charcoal rod 1, a round hole 3 is made in the middle of the fiber mattress 2, and the made bamboo charcoal rod 1 is put into the round hole 3 of the fiber mattress 2 to get final product. The diameter of the circular hole 3 in the fiber mattress 2 is 10-80mm, and the length is 10-200cm, which can be determined according to the size of the fiber mattress. The fiber mattress of the present invention refers to natural fiber mattresses made of mountain palm fiber, oil palm fiber, coconut shell fiber, hemp fiber, bamboo fiber and the like. The present invention will be further described below with different embodiments.

Embodiment 2

[0016] Embodiment 2 of the present invention: by weight, 70 to 95 parts of bamboo charcoal particles with a particle size of 0.1 to 5 mm are mixed with 5 to 30 parts of natural rubber latex at 10 to 40 ° C, molded into a rod or cylinder, and vulcanized after setting , soaked with clean water, rinsed, and dried to obtain the bamboo charcoal stick 1. According to the existing technology, the fiber sheets are obtained. In the process of making the fiber mattress with the fiber sheets, the wooden sticks are placed in the place where the round holes need to be set, and then the fiber sheets are overlapped, hot-pressed, vulcanized and shaped, and the wooden sticks are placed Pull out to get the fiber mattress 2 with the required round holes 3 , and according to the diameter of the round holes 3 , one to three layers of round holes 3 can be made on the fiber mattress 2 . Then the bamboo charcoal stick 1 is inserted into the round hole 3, and then the fiber mattress 2 is packaged with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com