Patents

Literature

45 results about "Arenga engleri" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arenga engleri, or the Formosa palm, Taiwan sugar palm, dwarf sugar palm, or Taiwan arenga palm, is a species of flowering plant in the family Arecaceae. The plant rarely grows more than 10 ft. tall, with a stem diameter of 6in. and a spread of 16 ft. The palm is native to Taiwan as well as Japan's Ryukyu Islands. The fruit of the palm is known to cause a severe allergic reaction.

Tourmaline-containing sheath-core composite fibers

ActiveCN104451940AHas antibacterial and antibacterial effectImprove itchingPhysical treatmentConjugated cellulose/protein artificial filamentsGlycerolSlurry

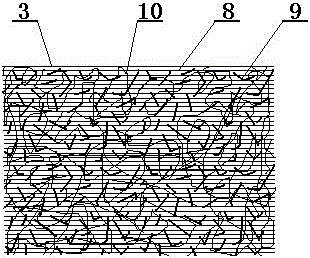

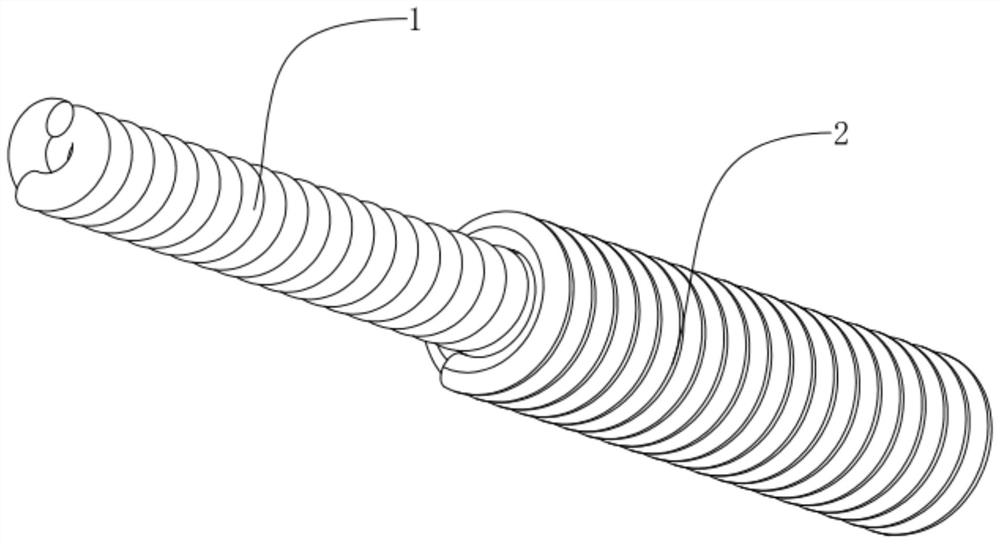

The invention relates to fibers, in particular to tourmaline-containing sheath-core composite fibers. The tourmaline-containing sheath-core composite fibers are prepared through the following steps: (1) tourmaline processing; (2) core layer material processing, that is, bast fibers and palm fibers after degumming processing are combed and cut into short bast fibers and short palm fibers, the short bast fibers and the short palm fibers are then soaked in a mixed manner in a lignocellulose aerogel solution for 15 to 20 minutes according to a formula, the short bast fibers and the short palm fibers after the mixed soaking are then taken out for draining, the short bast fibers and the short palm fibers after the draining are sent to an opener for opening and mixing, the short bast fibers and the short palm fibers after the opening and mixing pass through airflows and are arranged through a roller groove to form meshed semi-products with S-shaped section structures, and the meshed semi-products go through spunlace to form non-woven needled bast-palm fiber aerogel core layer materials; (3) sheath layer material processing, that is, a first pulp is prepared from processed tourmalines and ethylene glycol, phthalic acid and glycerol are used for esterification reaction, the first pulp, magnesium oxide and calcium hydroxide are added after the reaction for condensation polymerization, and polyester chip sheath layer materials are obtained through strip casting and sized dicing; (4) composite melt spinning for obtaining of the tourmaline-containing sheath-core composite fibers. The tourmaline-containing sheath-core composite fibers provided by the invention achieve the antibacterial and healthcare effects, high degree of comfort, as well as environment friendliness.

Owner:HEYE HEALTH TECH CO LTD

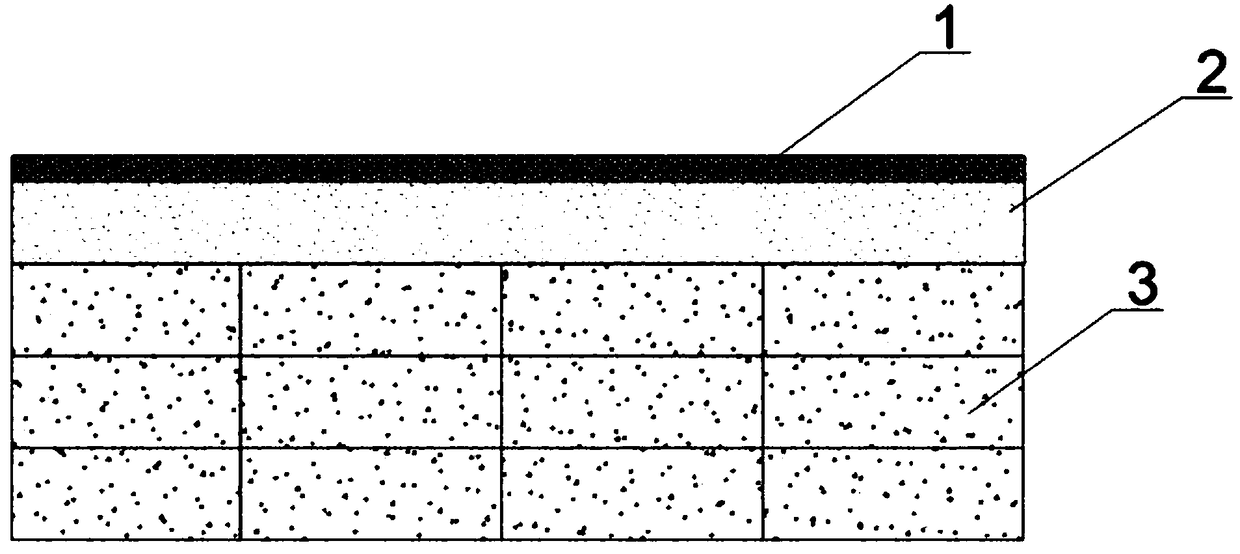

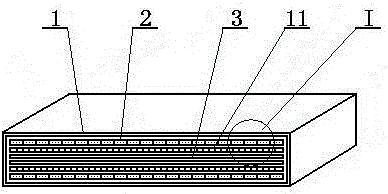

Composite arenga engleri and jute mattress

ActiveCN104305768AImprove antibacterial propertiesGood skin affinityStuffed mattressesNon-macromolecular adhesive additivesPunchingArenga engleri

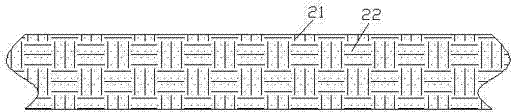

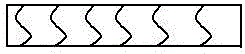

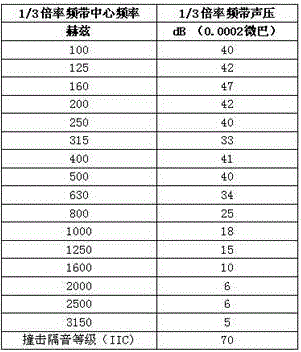

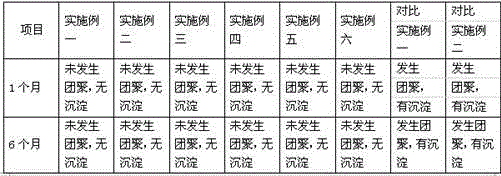

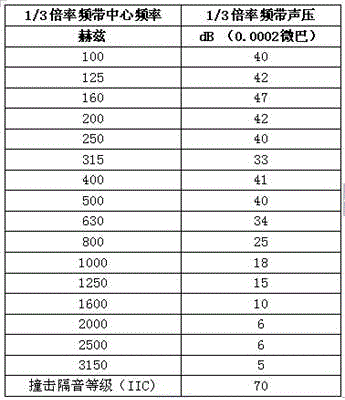

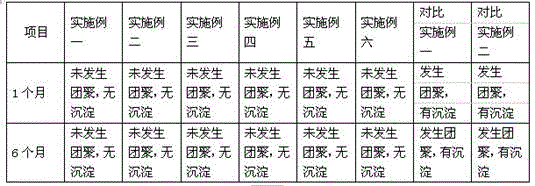

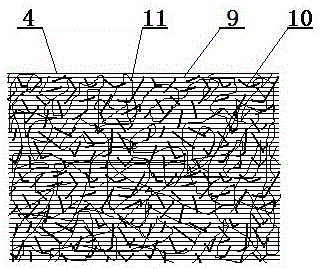

The invention relates to a fiber material, and in particular relates to a composite arenga engleri and jute mattress. The composite mattress is prepared through the following steps: preparing arenga engleri fiber: boiling and separating; before loosening, conducting primary bamboo vinegar treatment and secondary bamboo vinegar treatment to jute fiber and arenga engleri fiber; then implementing antibacterial treatment, mixing, dipping and loosening: degumming, carding and shorting, and dipping the short jute fiber and the short arenga engleri fiber which are mixed at a weight ratio of (30-40): (25-50) in lignocellulose aerogel liquid for 15-20min, taking out the mixture, draining off, and loosening and mixing in a loosening machine; carding and forming a net through an airflow: enabling loosened short jute fiber and short arenga engleri fiber drop uniformly from a roller groove through airflow, and uniformly arranging to form a net-shaped half-finished product with an S-shaped cross section; carrying out non-woven punching; roasting at high temperature, wherein the lignocellulose aerogel liquid is prepared by grinding, purifying, freezing and thawing, coagulating and regenerating. The composite arenga engleri and jute mattress disclosed by the invention is sound-insulating and heat-insulating, comfortable and environment-friendly, antibacterial and breathable, and long in service life.

Owner:HEYE HEALTH TECH CO LTD

Method for predicting contact stress between human body and mattress

InactiveCN108897930ALow costPredict and analyze contact stressDesign optimisation/simulationSpecial data processing applicationsHuman bodyDorsal parts

The invention discloses a method for predicting the contact stress between a human body and a mattress. The contact stress between the human body and an arenga engleri mattress is predicted and analyzed by adopting a method integrating a three-dimensional scanning technology and a finite element method; sensing cameras Kinect are used and are arranged on four columns respectively, a tester standsin a scanning range and keeps double arms slightly open, then point clouds on the surface of the human body can be scanned, a scanned human body model is processed by using Geomagic Studio to obtain asolid model of a subject; the obtained human body model is imported into grid generation software, material parameters of the mattress and the skin and muscles of the human body are input, and the contact stress between the human body and the mattress is predicted. Different users can select suitable mattresses according to the body pressure distribution situations on the mattresses made from different materials, accordingly back pain is effectively relieved, and the quality of sleep is improved.

Owner:JINAN UNIVERSITY

Formaldehyde-free adhesive and method for producing formaldehyde-free palm fiber mattress by using same

InactiveCN102618210ALow costSolve formaldehyde releaseStuffed mattressesProtein adhesivesCross-linkYarn

The invention discloses a formaldehyde-free adhesive and a method for producing a formaldehyde-free palm fiber mattress by using the formaldehyde-free adhesive. The formaldehyde-free adhesive is produced by using formaldehyde-free raw materials which are vegetable protein, a cross-linking agent, an auxiliary material and water. According to the method for producing the formaldehyde-free palm fiber mattress by using the formaldehyde-free adhesive, a palm fiber raw material is a natural coconut palm fiber yarn or a natural arenga engleri fiber yarn and is sequentially subjected to working procedures of felting, needling, glue spraying, drying, slicing, hot-pressing, side shearing and checking. The palm fiber mattress, the release amount of the free formaldehyde of which is far less than 0.050mg / m<2>.h (stated in QB1952.2-2004 spring soft mattress of upholstered furniture), can be produced according to the method. The free formaldehyde of the palm fiber mattress is only derived from the natural palm fiber, thereby the problem of formaldehyde release of the palm fiber mattress is fundamentally solved.

Owner:田志壮

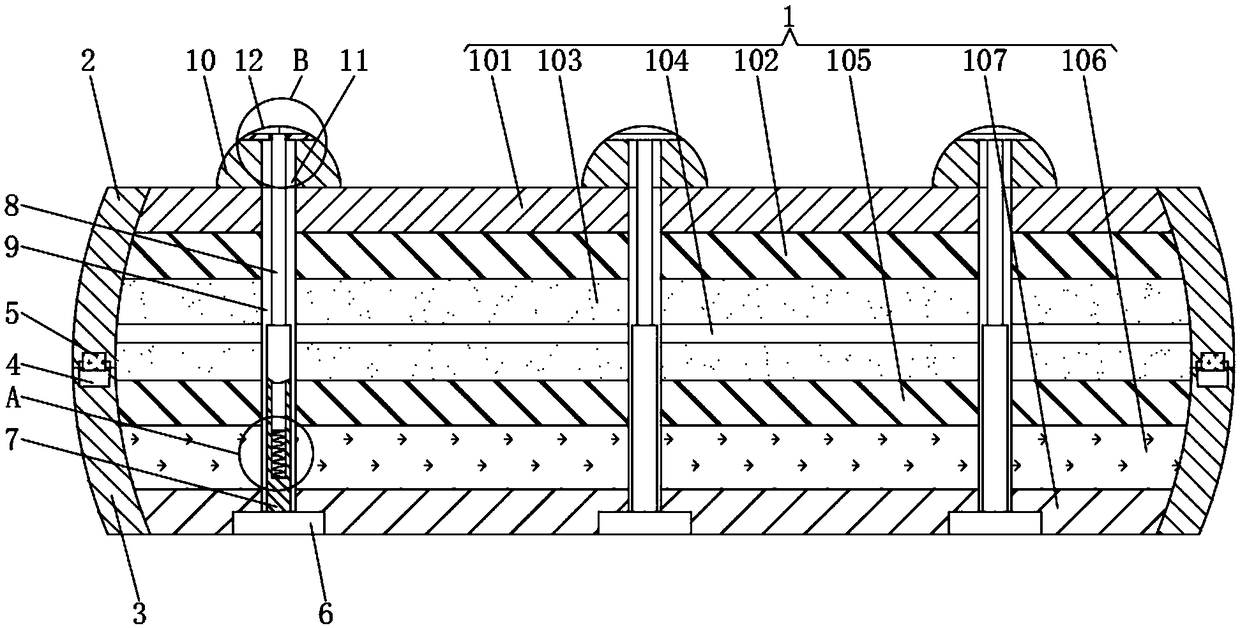

Health-care hemp palm aerogel composite bed core material

ActiveCN104389108ARelieve pressurePromote circulationStuffed mattressesSpring mattressesAntibiosisFreeze thawing

The invention relates to a fiber material, in particular to a health-care hemp palm aerogel composite bed core material. The health-care hemp palm aerogel composite bed core material is prepared by the following steps of: mixed dipping and opening: firstly, hemp fiber and arenga engleri fiber are subjected to degumming treatment, and are then subjected to carding and are shortly cut into short hemp fiber and short palm fiber, then, the short hemp fiber and the short palm fiber are subjected to mixed dipping for 15 to 20 minutes in lignocellulose aerogel liquid according to a weight ratio being (30-40):(25-50), next, the short hemp fiber and the short palm fiber are taken out and drained off and are conveyed into an opening machine to be opened and mixed; air flow carding for forming nets: the short hemp fiber and the short palm fiber subjected to opening uniformly go down from a rolling cylinder groove through air flow and are uniformly ranged into reticular semi-finished products with the S-shaped cross section structure; non-woven acupuncture; high-temperature baking. A preparation method of lignocellulose aerogel liquid comprises the steps of pulverization, purification, freezing thawing and solidification regeneration. The health-care hemp palm aerogel composite bed core material has the advantages of sound isolation, heat isolation, comfort, environment protection, antibiosis, ventilation and long service life.

Owner:HEYE HEALTH TECH CO LTD

Method for increasing germination speed of arenga engleri seeds

InactiveCN102626012AGood for seedling productionPromote germinationSeed and root treatmentGreeningArenga engleri

The invention belongs to the technical field of reproduction of plant seedlings and relates to a method for increasing germination speed of arenga engleri seeds. The method comprises the following steps of: immediately removing seed husks of newly harvested, mature and plump arenga engleri seeds, and then putting into a squeezed arenga engleri seed husk juice to be soaked for 6-8 days; taking out the seeds soaked in the arenga engleri seed husk juice and then soaking in clean water till germination occurs. According to the method for increasing germination speed of arenga engleri seeds, the arenga engleri seed husk juice is adopted for soaking the arenga engleri seeds, so that the germination of the seeds is promoted and problems of long germination time and low germination rate of arenga engleri seeds in the prior art can be solved effectively; and the method for increasing germination speed of arenga engleri seeds has the advantages of simple process, low cost, short germination time and uniform germination and the like, is beneficial to large-scale production of arenga engleri seedlings and provides an effective manner for the popularization and application of arenga engleri seedlings in landscape greening.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

Horizontal barrier material for risk management and control of polluted land parcel and preparation method

The invention provides a horizontal barrier material for risk management and control of a polluted land parcel and a preparation method, belonging to the technical field of risk management and controlof polluted land parcels. The material comprises modified natural short fibers, a powder material and a liquid material in a mass ratio of 1: 20: 17, wherein the modified natural short fibers are modified jute fibers or modified Arenga engleri fibers with length of 2-6 mm; the powder material comprises Portland cement, ground calcium carbonate and quartz powder; the liquid material comprises a polymer emulsion, a defoaming agent, a coalescing agent, a compatibilizer, a dispersing agent and deionized water. The preparation method comprises the following steps: pouring the liquid material intoa container, carrying out uniform mixing, and adding a mixture obtained by uniformly mixing the modified natural short fibers and the powder material; and carrying out stirring for 10-20 minutes to obtain slurry liquid without block mass flow, thereby obtaining the material. The horizontal barrier material provided by the invention has the advantages of easy availability of raw materials, low cost, simple preparation method and excellent barrier properties, can block the migration of a polluted medium to a surrounding environment, and can provide a good in-situ horizontal barrier for the polluted land parcel after application.

Owner:ZHENGZHOU UNIV +1

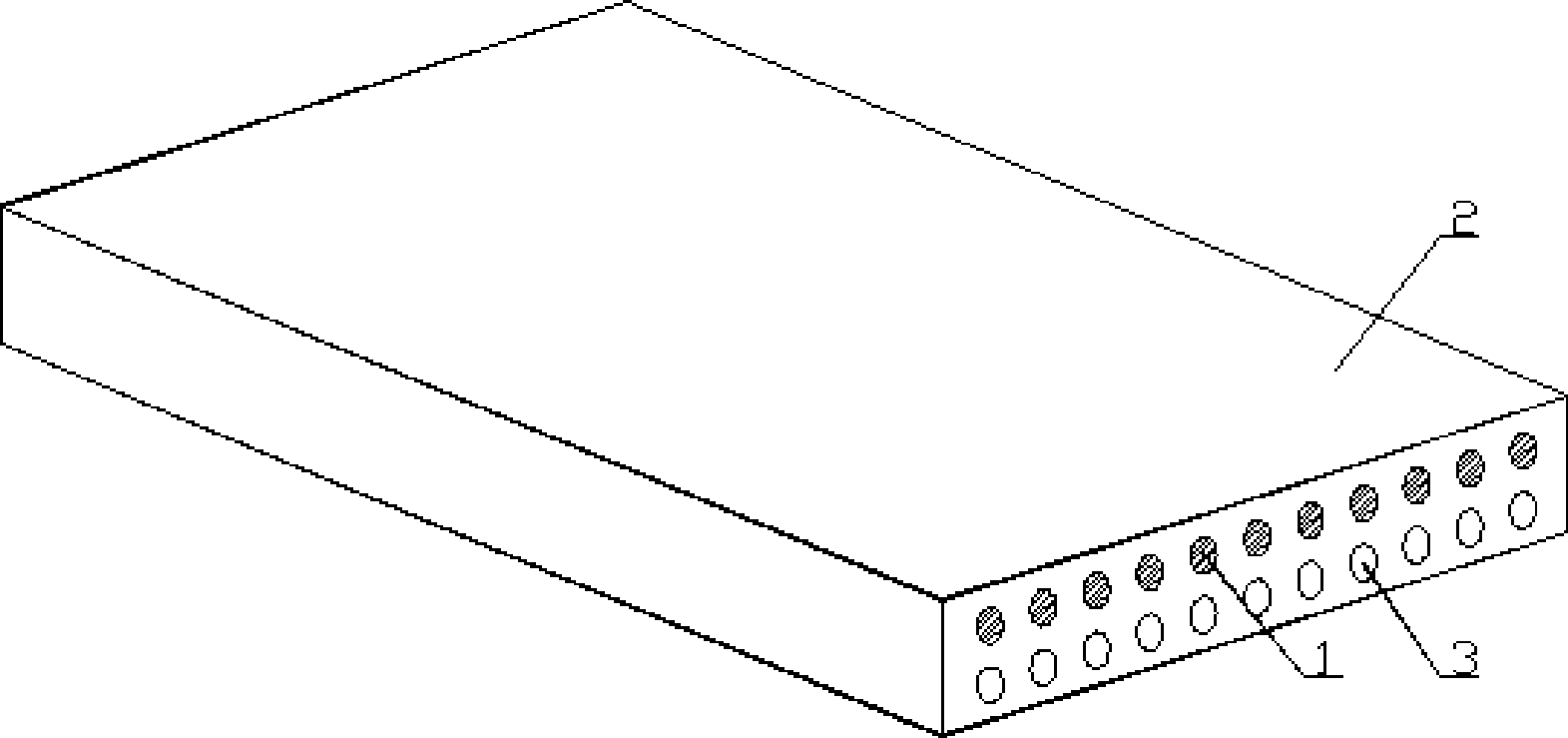

Latexes bamboo charcoal stick fiber mattress and production method

ActiveCN101371740AElasticity does not affectStay flexibleUpholstery manufactureStuffed mattressesMildewArenga engleri

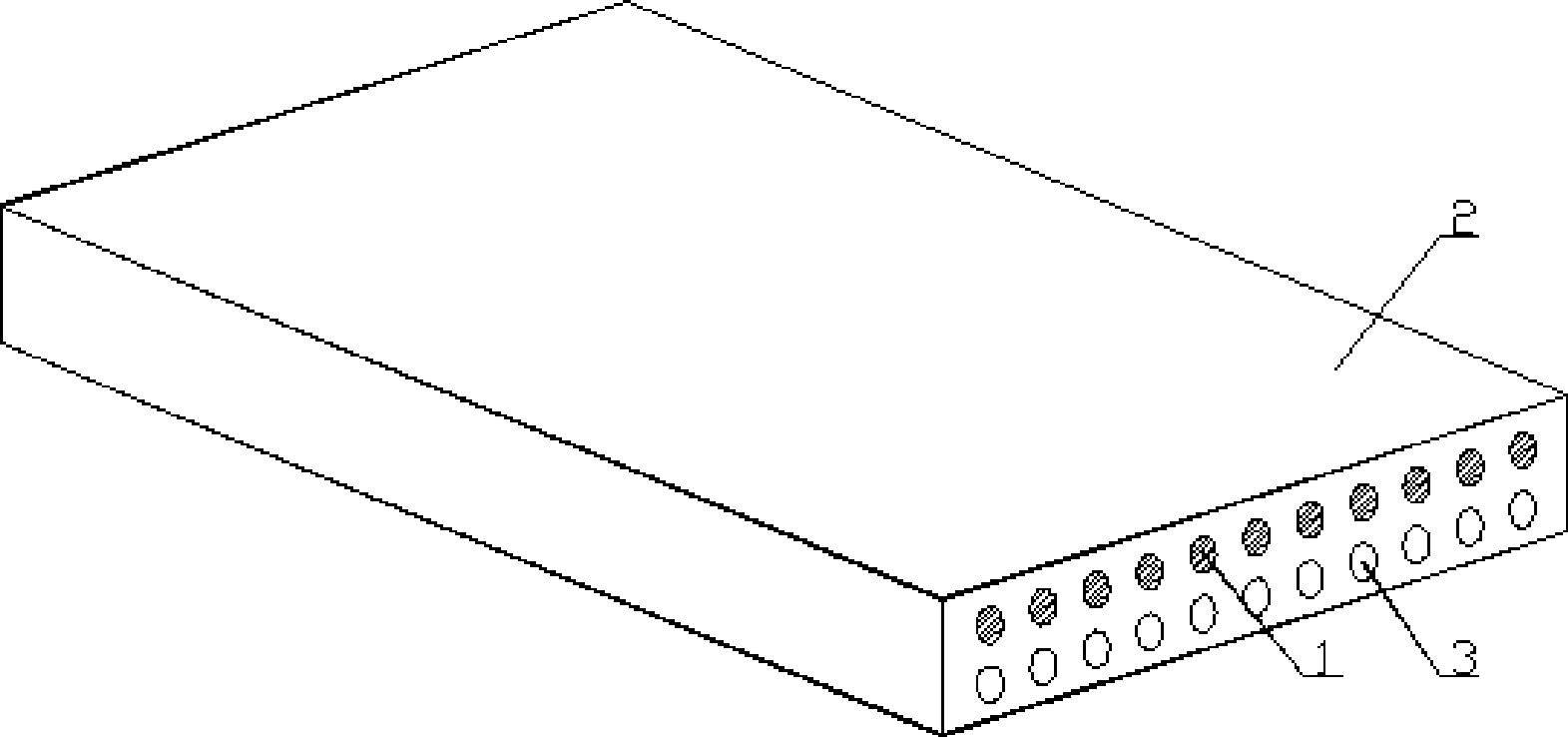

The invention discloses a latex bamboo carbon rod fiber mattress and a preparation method; the bamboo carbon grains are prepared as bamboo carbon rods; round holes are prepared in the middle of the fiber mattress; the prepared bamboo carbon rod is arranged into the round holes of the fiber mattress; the mattress uses solid bamboo carbon rods or cylindrical bamboo carbon rods made of purely natural bamboo carbon and uses special technology for processing so as to be prepared; the mattress is provided with a certain elasticity; when being arranged in the round holes of the mattress, the elasticity and softness of the mattress are not affected; on the basis of keeping the comfortableness of the original fiber mattress, the bamboo carbon is added, thus leading the mattress to have the functions of anti-moisture, anti-mildew, deodorization and air purification and keeping the dryness and cleanness of the mattress. The mattress has the advantages that the bamboo carbon inside the mattress can be replaced, the efficacy of the bamboo carbon can be sufficiently exerted, dryness and cleanness of the mattress can be kept, and the like, and is applicable for the mattress prepared by various natural fiber mattress such as arenga engleri fiber, oil palm fiber, coconut fiber, linen fiber, bamboo fiber, etc.

Owner:GUIZHOU DAZIRAN TECH

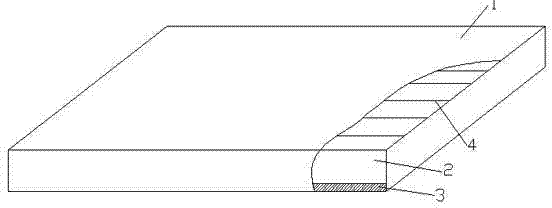

Arenga engleri Beccari fiber mattress and manufacture method thereof

InactiveCN104720428APlay the function of sterilization and disinfectionImprove efficiencyStuffed mattressesSpring mattressesActivated carbonWear resistant

Disclosed are an Arenga engleri Beccari fiber mattress and a manufacture method thereof. The mattress comprises an Arenga engleri Beccari fiber layer and a wear resistant layer. The Arenga engleri Beccari fiber layer is sewed above the wear resistant layer and is formed through paved and arranged natural Arenga engleri Beccari fibers, and the surfaces of the natural Arenga engleri Beccari fibers are provided with a plurality of activated carbon particles. The mattress is sewed mechanically, conveniently, rapidly and efficiently, the natural Arenga engleri Beccari fibers are adopted, the activated carbon particles with the absorption and environment-protection capabilities are arranged on the natural Arenga engleri Beccari fibers, the connatural three-dimensional reticular fiber structure of the natural Arenga engleri Beccari fibers is utilized completely, the indoor air can be sterilized and disinfected, the strength is high, the pressure of 8ton can be borne, and the mattress has the advantages of water and air permeability, insect prevention and bacteria resistance, environment protection and health caring.

Owner:HUANGHUA LVXIANG ZONGDIAN PROD

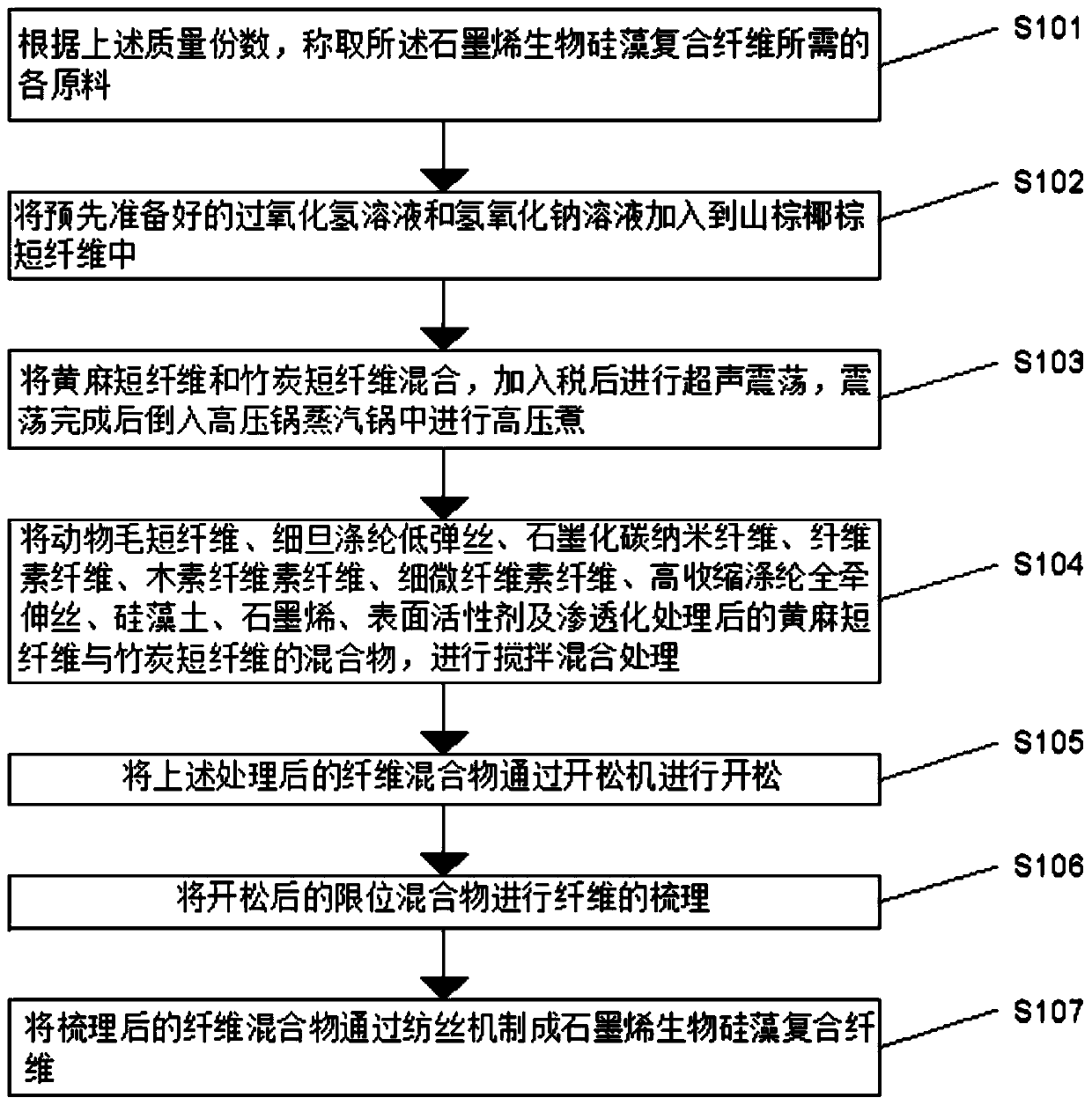

Graphene biologic diatom compound fiber and preparation method and application thereof

PendingCN108374218AEliminate odorRelease negative oxygen ionsStuffed mattressesPhysical treatmentOxygen ionsGraphene

The invention relates to a fiber and a preparation method and application thereof, in particular to a graphene biologic diatom compound fiber and a preparation method and application thereof. The graphene biologic diatom compound fiber is prepared from, by weight, 50-60% of arenga engleri coconut short fibers, 5-10% of jute short fibers, 5-10% of bamboo carbon short fibers, 5-10% of animal hair short fibers, 1-10% of graphene, 2-10% of diatomite and 2-5% of surfactant. The preparation method of the compound fiber comprises the steps of (1) weighing and acquiring of raw materials; (2) pretreatment of the arenga engleri coconut short fibers; (3) permeation treatment; (4) mixing; (5) opening; (6) carding; (7) acquiring of finish products. The fiber can be applied to home supplies, especiallya mattress. The fiber and the mattress have the advantages of being dampproof, antiseptic, resistant to deformation, capable of preventing damage caused by worms, breathable, antibacterial, capable ofpurifying the air, removing odor, adjusting humidity through ventilation and releasing negative oxygen ions and the like.

Owner:QINGDAO YUWANG BED

Bamboo charcoal stick fiber mattress and production method

ActiveCN101371739AElasticity does not affectStay flexibleStuffed mattressesSpring mattressesArenga engleriNatural fiber

The invention discloses a bamboo carbon rod fiber mattress and a preparation method; the bamboo carbon grains are prepared as bamboo carbon rods; round holes are prepared in the middle of the fiber mattress; the prepared bamboo carbon rod is arranged into the round holes of the fiber mattress; the mattress uses solid bamboo carbon rods or cylindrical bamboo carbon rods made of purely natural bamboo carbon and uses special technology for processing so as to be prepared; the mattress is provided with a certain elasticity; when being arranged in the round holes of the mattress, the elasticity and softness of the mattress are not affected; on the basis of keeping the comfortableness of the original fiber mattress, the bamboo carbon is added, thus leading the mattress to have the functions of anti-moisture, anti-mildew, deodorization and air purification and keeping the dryness and cleanness of the mattress. The mattress has the advantages that the bamboo carbon inside the mattress can be replaced, the efficacy of the bamboo carbon can be sufficiently exerted, dryness and cleanness of the mattress can be kept, and the like, and is applicable to the mattress prepared by various natural fiber mattress such as arenga engleri fiber, oil palm fiber, coconut fiber, linen fiber, bamboo fiber, etc.

Owner:GUIZHOU DAZIRAN TECH

Graphene biological diatom composite fiber as well as preparation method and application thereof

InactiveCN110952169AImprove wear resistanceImprove stress resistanceStuffed mattressesSpring mattressesPolyesterYarn

The invention discloses a graphene biological diatom composite fiber as well as a preparation method and application thereof. The graphene biological diatom composite fiber is prepared from the following raw materials in parts by mass: 40 to 50 parts of arenga engleri and coconut staple fibers, 20 to 30 parts of fine-denier draw texturing yarn, 10 to 20 parts of jute staple fibers, 10 to 20 partsof graphitized carbon nanofibers, 5 to 10 parts of bamboo charcoal staple fibers, 10 to 15 parts of animal wool staple fibers, 1 to 5 parts of graphene, 1 to 10 parts of diatomite, 1 to 2 parts of tourmaline powder, 5 to 10 parts of cellulose fibers, 10 to 20 parts of ligno-ccllulose fibers, 10 to 15 parts of fine cellulose fibers, 20 to 30 parts of high shrinkage polyester fully drawn yarn and 2to 8 parts of surfactants. The composite fiber has the beneficial effects that the ligno-ccllulose fibers, the fine-denier draw texturing yarn, the high shrinkage polyester fully drawn yarn and the like are added, so that the wear resistance, the pressure resistance, the high temperature resistance, the elasticity and the like of the composite fiber are improved.

Owner:QINGDAO YUWANG BED

Preparation method of moistureproof plasterboard

The invention belongs to the technical field of sheet material preparation, and more specifically relates to a preparation method of a moistureproof plasterboard. The preparation method comprises following steps: wollastonite is taken as a raw material, and is mixed with distilled water to prepare a wollastonite suspension solution; the wollastonite suspension solution is reacted with hydrochloricacid so as to obtain a mixed solution, and the mixed solution and sunflower oil are subjected to blending fermentation so as to obtain modified wollastonite; arenga engleri is taken as a raw material, and is subjected to gas explosion treatment so as to obtain arenga engleri fiber; isopropanol is taken as an alkylating agent for alkylation processing of arenga engleri fiber so as to obtain alkylated arenga engleri fiber which is taken as modified arenga engleri fiber; orange peel essential oil is taken as a raw material, the modified arenga engleri fiber and orange peel essential oil are mixed, stirred, and reacted so as to obtain a mixture; and at last, the modified wollastonite and the mixture are mixed for reaction, an obtained product is introduced into a die for curing and drying soas to obtain the moistureproof plasterboard. The moistureproof plasterboard is low in water absorption rate, and excellent in moisture resistance, at an environment with relatively large temperature difference, cracking times are few, compressive strength is high, impact resistance is excellent, and the application prospect is promising.

Owner:吕贻秀

Method for extracting fibrous filaments from arenga engleri becc petiole

The invention discloses a method for extracting fibrous filaments from arenga engleri becc petioles, which comprises the following steps that the arenga engleri becc petioles are cooked in a steamer with a pressure of 0.2 to 0.3 MPa and a temperature of 120 DEG C for 4 to 6 hours, the selected arenga engleri becc petioles are made into fiber by a fiber-yarn making machine to obtain fibrous filaments, the fibrous filaments are conveyed by a conveyor to a screening machine for screening, removing impurities and broken filaments in the filaments, and the selected fibrous filaments are passed to a dryer through a conveyor for drying under the drying temperature of 140 to 160 DEG C for 30 to 45 minutes. The method for extracting fibrous filaments from arenga engleri becc petioles adopts a high temperature and high pressure cooking method to greatly shorten the cooking time of the arenga engleri becc petioles, the arenga engleri becc petioles are made into fiber by the fiber-yarn making machine, which not only saves the labor cost, but also improves the efficiency of making fiber. Finally, the dryer is used for drying the fibrous filaments after screening. The drying cycle is short, and the technical problems in the prior art of long drying time and large volume hot air consumption are solved.

Owner:GUIZHOU DAZIRAN TECH

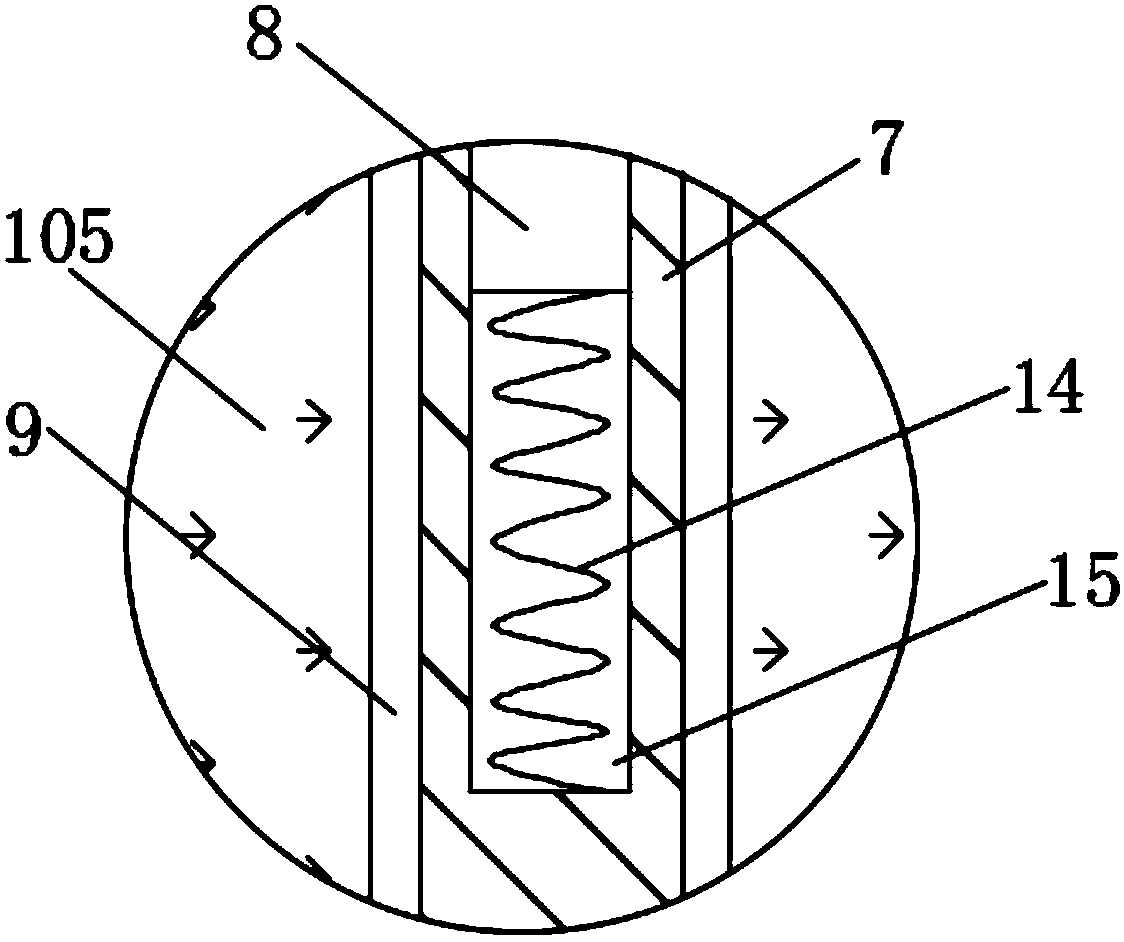

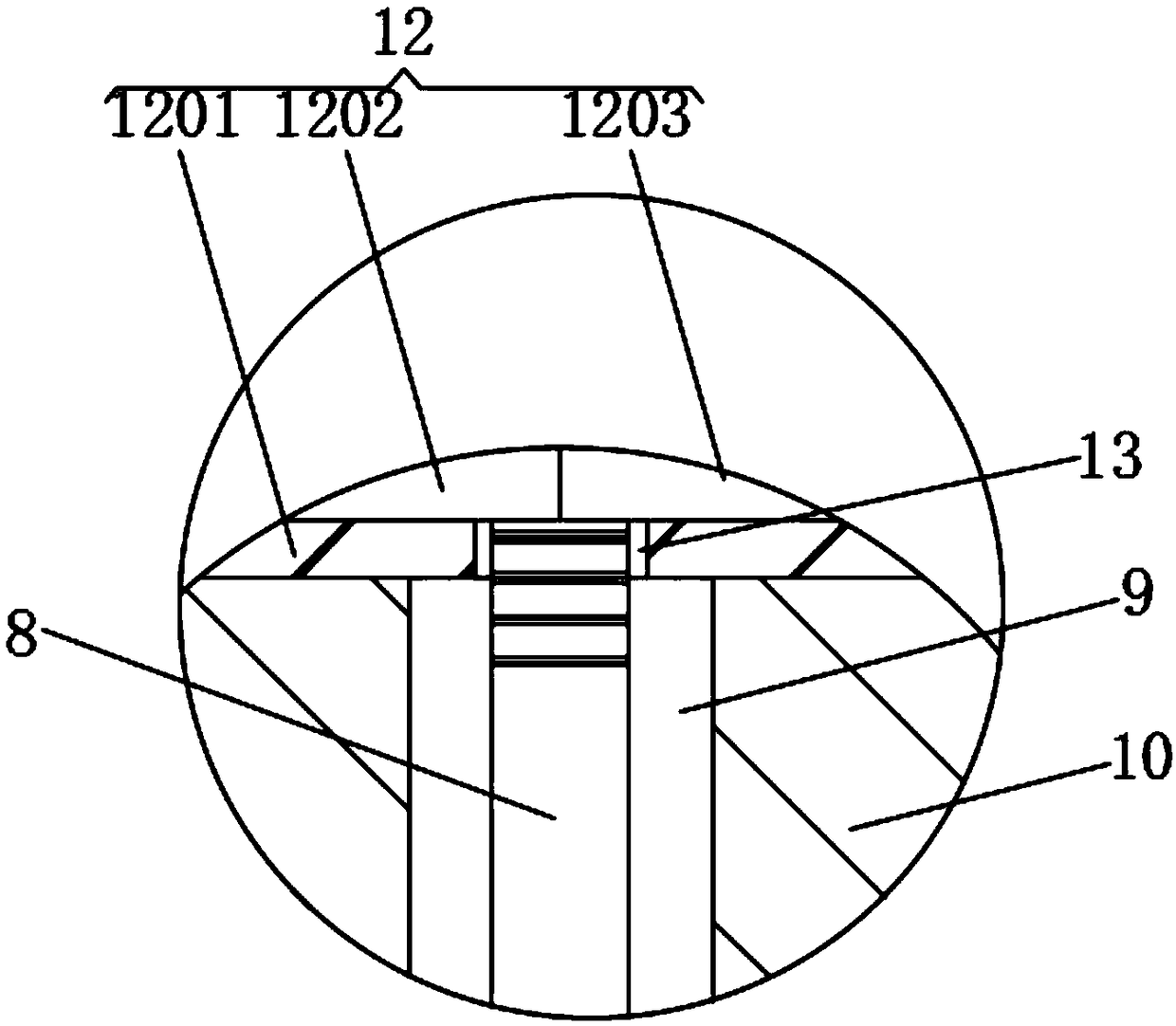

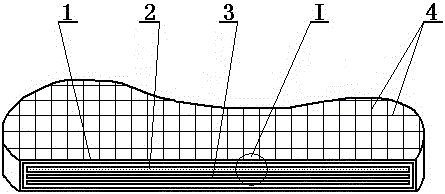

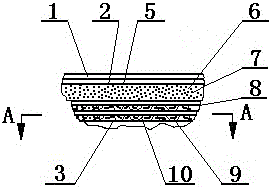

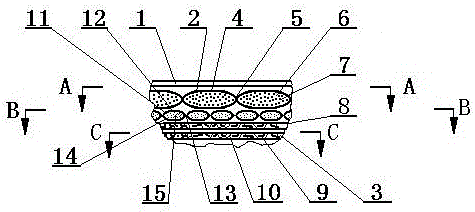

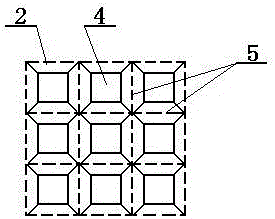

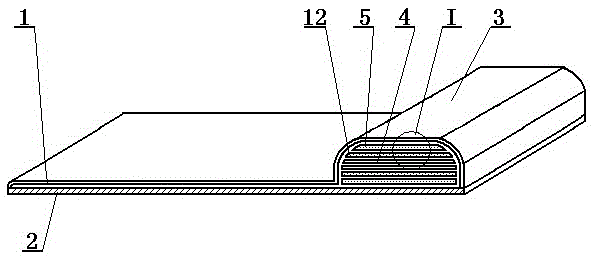

Deodorant, antibacterial and hygroscopic healthcare drug insole

The invention discloses a deodorant, antibacterial and hygroscopic healthcare drug insole. The deodorant, antibacterial and hygroscopic healthcare drug insole comprises an insole body, concave-convexmassage anti-slip cloth, a first high-temperature resistant PC non-woven fabric, a packing layer, a high-temperature far-infrared anion carbon layer, a second high-temperature resistant PC non-woven fabric, a natural arenga engleri beccari layer, a needling 3D polygonal breathable mesh, first insole edge cloth, second insole edge cloth, a first hook-and-look fastener, a second hook-and-look fastener, fixing pieces, connecting rods, straight bars, circular holes, lugs, through holes, massage heads, circular pieces, germanite blocks, magnet blocks, threaded holes, springs and sliding holes. Thedeodorant, antibacterial and hygroscopic healthcare drug insole has the advantages that the structure is reasonable, the foot sole of a user can be effectively massaged, the massage effect can be improved through the straight bars, the connecting rods and the elasticity of the springs, and the blood circulation of the foot sole can be promoted through the cooperation of far-infrared rays and starting waves of the high-temperature far-infrared anion carbon layer, germanite blocks and magnet blocks, so that the deodorant, antibacterial and hygroscopic healthcare drug insole has the healthcare effect.

Owner:ZHEJIANG BAISHAN CHARCOAL IND TECH

Green, environment-friendly and safe insole with multiple healthcare functions

InactiveCN105729925AEliminate odorImprove quality requirementsInsolesLayered productsCotton clothEngineering

The invention discloses an environmental protection and safety insole with multiple health care functions. The main features are: the upper part of the inner cavity of the insole cover is provided with a litsea cubeba cushion, and the lower part of the litsea cubeba cushion is provided with 1 to 3 layers of neatly stacked tea stalk mixed cushions; the litsea cubeba cushion is formed from the upper Litsea Cubeba is composed of cotton cloth layer, lower cotton cloth layer and Litsea Cubeba. The Litsea cubeba is laid flat in the insole-shaped closed bag with the length and width meeting the requirements sewn by the upper and lower cotton cloth layers; Composed of stalks and pure cotton silk; after the mixed cushion layer of litsea cubeba and tea stems is put into the inner cavity of the insole cover, the mixed cushion layer of litsea cubeba and tea stems is sewed tightly on the insole cover with sutures crossing each other Inside. The invention has multiple health care functions, is environmentally friendly, safe, can deodorize and sterilize, and meets modern people's high-quality requirements for life.

Owner:罗云

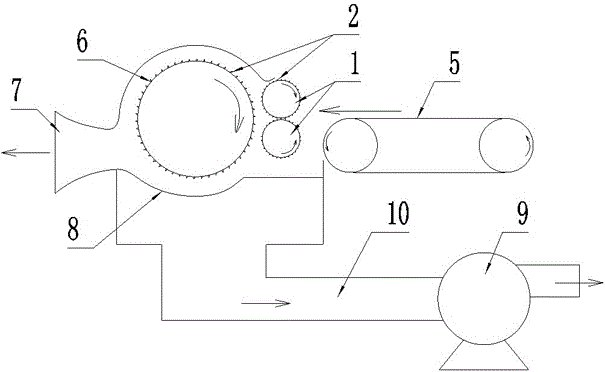

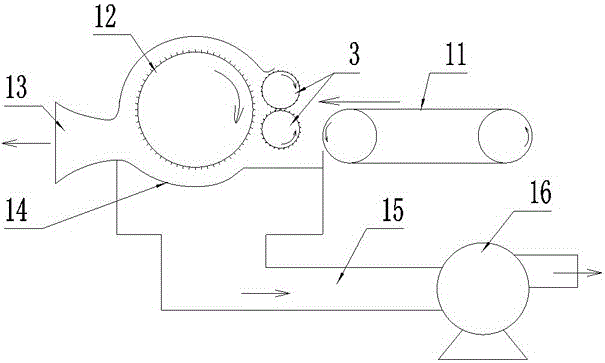

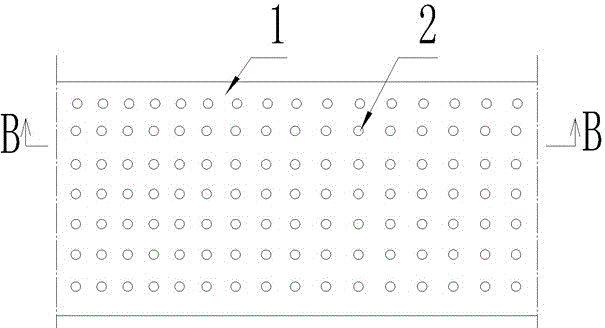

Process for producing core stock of non-adhesive arenga engleri mattress and drawing machine and impurity removal machine

PendingCN105755881ASimple structureEasy to operateCarding machinesNon-woven fabricsPolyesterPulp and paper industry

The invention discloses a process for producing core stock of a non-adhesive arenga engleri mattress, a drawing machine and an impurity removal machine, and relates to the technical field of production of upholstered furniture supplies. The process comprises the following steps: drawing and removing impurities from arenga engleri bark, selecting arenga engleri fibers, uniformly mixing with polyester fibers according to a ratio, and removing the impurities to enable the monofilaments to be uniform in thickness; sequentially stretching, interweaving and laying net to form a three-dimensional meshed shape, drying the meshed monofilaments at a high temperature, cooling and setting; finally, trimming to obtain the finished product. The drawing machine and the impurity removal machine are used for drawing, crimping and removing dust and impurities, the structure is simple, the operation is convenient, and the working efficiency is improved. The production process disclosed by the invention is simple and easy to operate, no adhesive is added in the production process, and the process is pollution-free, formaldehyde-free, green and environmental-friendly.

Owner:河北自然梦家具有限公司

Stone needle composite yarn, cloth and preparation method of stone needle composite yarn

ActiveCN111876873AAchieve release effectTrigger release effectMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnPolyester

The application discloses a stone needle composite yarn, cloth and a preparation method of the stone needle composite yarn, and relates to the technical field of magnetic therapy health care. The stone needle composite yarn comprises two polyester wire cores of a double-helix winding structure and cellulose staple fiber yarns wrapping and winding the two polyester wire cores; the polyester wire cores contain 10-30% by mass of stone needles; and the cellulose staple fiber yarns contain 2.4-7.2% by mass of arenga engleri. According to the application, 10-30% by mass of the stone needles are added into the two polyester wire cores which are of a double-helix winding structure, so that the stone needles rub against the cellulose staple fiber yarns wrapped and wound on the two polyester wire cores, and the two polyester wire cores rub against each other, thereby achieving the effect of stimulating the release of the stone needles; and besides, 2.4-7.2% by mass of the arenga engleri is addedinto the cellulose staple fiber yarns, so that the structural strength and the distribution uniformity of the yarns are improved through the arenga engleri which is free from fat, low in heat energyand high in fiber, and the magnetic therapy health care effect is improved.

Owner:HEYE HEALTH TECH CO LTD

Method for preparing arenga engleri mat through plant cementing compound

InactiveCN107030842ANo harmNo added hazardNon-macromolecular adhesive additivesProtein adhesivesEngineeringArenga engleri

The invention discloses a method for preparing an arenga engleri mat through a plant cementing compound. Firstly, arenga engleri silks are dried, the dried arenga engleri silks are sprayed with the cementing compound, the cementing spraying amount is 10%-20% of the mass of the arenga engleri silks, heating and drying are carried out, and pressing and shaping are carried out for manufacturing the arenga engleri mat; secondly, the surface of the shaped arenga engleri mat is subject to cementing spraying treatment, and the cementing spraying amount is 10%-20% of the mass of the arenga engleri silks; and thirdly, the arenga engleri mat obtained after cementing spraying is stacked and is subject to stacking and shaping according to needed thicknesses, and the arenga engleri mat is packed after being cut, and a finished product is obtained. The cementing compound is a natural plant cementing compound. The arenga engleri mat prepared through the plant cementing compound is environment-friendly, free of formaldehyde and other volatile organic compounds, appropriate in elasticity and good in durability.

Owner:思南县唯一山棕制品厂

A kind of health hemp palm airgel composite bed core material

ActiveCN104389108BUnique polygonal structureImprove breathabilityStuffed mattressesSpring mattressesFreeze thawingAntibiosis

The invention relates to a fiber material, in particular to a health-care hemp palm aerogel composite bed core material. The health-care hemp palm aerogel composite bed core material is prepared by the following steps of: mixed dipping and opening: firstly, hemp fiber and arenga engleri fiber are subjected to degumming treatment, and are then subjected to carding and are shortly cut into short hemp fiber and short palm fiber, then, the short hemp fiber and the short palm fiber are subjected to mixed dipping for 15 to 20 minutes in lignocellulose aerogel liquid according to a weight ratio being (30-40):(25-50), next, the short hemp fiber and the short palm fiber are taken out and drained off and are conveyed into an opening machine to be opened and mixed; air flow carding for forming nets: the short hemp fiber and the short palm fiber subjected to opening uniformly go down from a rolling cylinder groove through air flow and are uniformly ranged into reticular semi-finished products with the S-shaped cross section structure; non-woven acupuncture; high-temperature baking. A preparation method of lignocellulose aerogel liquid comprises the steps of pulverization, purification, freezing thawing and solidification regeneration. The health-care hemp palm aerogel composite bed core material has the advantages of sound isolation, heat isolation, comfort, environment protection, antibiosis, ventilation and long service life.

Owner:HEYE HEALTH TECH CO LTD

A kind of mountain palm jute composite mattress

ActiveCN104305768BGood antibacterial and bactericidal effectHigh reactivityStuffed mattressesNon-macromolecular adhesive additivesPunchingReticulate

The invention relates to a fiber material, and in particular relates to a composite arenga engleri and jute mattress. The composite mattress is prepared through the following steps: preparing arenga engleri fiber: boiling and separating; before loosening, conducting primary bamboo vinegar treatment and secondary bamboo vinegar treatment to jute fiber and arenga engleri fiber; then implementing antibacterial treatment, mixing, dipping and loosening: degumming, carding and shorting, and dipping the short jute fiber and the short arenga engleri fiber which are mixed at a weight ratio of (30-40): (25-50) in lignocellulose aerogel liquid for 15-20min, taking out the mixture, draining off, and loosening and mixing in a loosening machine; carding and forming a net through an airflow: enabling loosened short jute fiber and short arenga engleri fiber drop uniformly from a roller groove through airflow, and uniformly arranging to form a net-shaped half-finished product with an S-shaped cross section; carrying out non-woven punching; roasting at high temperature, wherein the lignocellulose aerogel liquid is prepared by grinding, purifying, freezing and thawing, coagulating and regenerating. The composite arenga engleri and jute mattress disclosed by the invention is sound-insulating and heat-insulating, comfortable and environment-friendly, antibacterial and breathable, and long in service life.

Owner:HEYE HEALTH TECH CO LTD

Preparation method of arenga engleri plant fiber sheet

InactiveCN109514684AImprove structural strengthLow densityWood working apparatusFlat articlesDrying timeArenga engleri

The invention discloses a preparation method of an arenga engleri plant fiber sheet. The preparation method comprises the steps that a, after being curled, arenga engleri filaments are blown by airflow to be three-dimensionally distributed; b, a binding agent is sprayed to the curled arenga engleri filaments three-dimensionally distributed so that the arenga engleri filaments can be subjected to joint binding; c, the arenga engleri filaments with the binding agent sprayed are dried; and d, the plant fiber sheet is obtained after the arenga engleri filaments are dried. In the step b, the weightratio of the arenga engleri filaments to the binding agent is (0.6-1.5):1, and the solid content of latex in the binding agent ranges from 45% to 55%. The preparation method has the advantages that the elasticity of the fiber sheet is improved, the density of the fiber sheet is reduced, and the drying time is shortened.

Owner:GUIZHOU DAZIRAN TECH

Wood fiber capable of radiating far-infrared rays and manufacturing method thereof

The invention discloses a wood fiber capable of radiating far-infrared rays, which is characterized by comprising the following raw materials in parts by weight: 40-44 parts of wood fiber, 7-9 parts of fine wool cotton fiber, 5-8 parts of viscose fiber, 6-10 parts of Arenga engleri Beccari fiber, 20-25 parts of sugarcane peel, 17-19 parts of tea leftovers, 1-3 parts of infrared ceramic powder, 1.2-2.5 parts of polystyrene nanoparticle, 4-7 parts of carnauba wax, 10-13 parts of ethanol, 4-8 parts of polyvinylacetal, 0.3-0.7 part of dioctyltin dilaurate, 3-4 parts of markka, 2-4 parts of corydalis tuber, 1-2 parts of radix salviae miltiorrhizae, 3-6 parts of assistant and a right amount of water. By optimizing the production technique and adding the infrared ceramic powder, the wood fiber can radiate far-infrared rays, and has the advantages of diminishing inflammation, promoting the subsidence of swelling, resisting bacteria, enhancing the cell regeneration capacity and immunological cell functions and the like when acting on the human body. Besides, the multiple animal and plant fibers are added and mutually compounded, thereby saving the cost and enhancing the characteristics of the wood fiber. The prepared wood fiber is widely used in the fields of medical treatment and recovery.

Owner:安徽坤城木艺有限公司

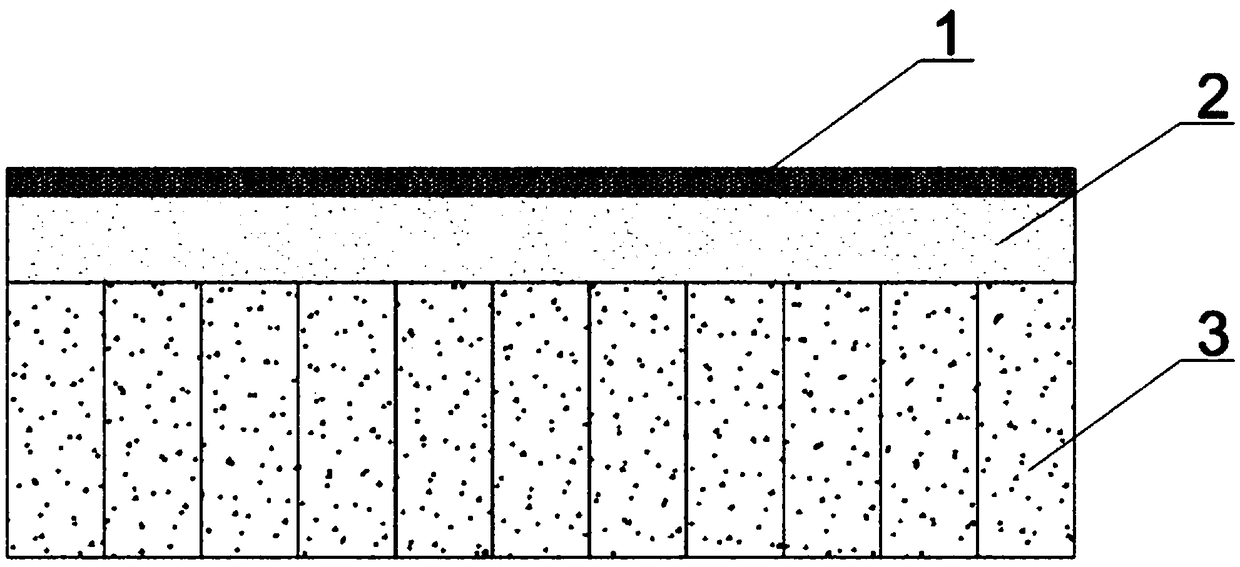

Healthcare environment-friendly coir mattress preparation method

InactiveCN107252213AOvercome the disadvantage of being thinIncreasing the thicknessBiocideStuffed mattressesCooking & bakingAromatherapy

The invention discloses a healthcare environment-friendly coir mattress preparation method. A healthcare environment-friendly coir mattress comprises an upper layer and a lower layer; the upper layer is made by steps of mixing of bamboo charcoal fiber and traditional Chinese medicine mixed powder with low-melting-point fibers, high-temperature baking, pressing and cooling moulding; the lower layer is made from arenga engleri fibers and low-melting-point fibers by high-temperature baking, pressing and cooling moulding. The healthcare environment-friendly coir mattress has advantages of aromatherapy, sleeping promotion, environmental friendliness and freeness of formaldehyde.

Owner:思南县唯一山棕制品厂

Environment-friendly and safe pillow with magnet therapy effect and multiple healthcare functions

InactiveCN105747719AImprove air qualityWith head windPillowsElectrotherapyIndoor air qualityArenga engleri

The invention discloses an environment-friendly and safe pillow with a magnet therapy effect and multiple healthcare functions. The pillow is mainly characterized in that litsea cubeba seed cushion layers are arranged on the upper layer and the lower layer of an inner cavity of a pillow case respectively, magnetic powder cushion layers are arranged on the lower surface of the upper litsea cubeba seed cushion layer and the upper surface of the litsea lower cubeba seed cushion layer respectively, and a plurality of orderly-stacked tea stalk mixed cushion layers are arranged between the upper magnetic powder cushion layer and the lower magnetic powder cushion layer; each litsea cubeba seed cushion layer is composed of an upper cotton layer, a lower cotton layer and litsea cubeba seeds; each magnetic powder cushion layer is composed of an upper flannel layer, a lower flannel layer and magnetic powder, wherein the magnetic powder is evenly spread on the oppositely-attached flock surfaces of the upper flannel layer and the lower flannel layer and is sewn in a square second sealed bag with the width of 10-30 mm through a second sewing thread; each tea stalk mixed cushion layer is prepared from arenga engleri fibers, tea stalks and pure cotton fibers. The pillow has a magnet therapy effect and multiple healthcare functions, is environmentally friendly and safe and can purity air in a bedroom and improve the air quality in the bedroom to meet the requirement of modern people for high living quality.

Owner:罗建华

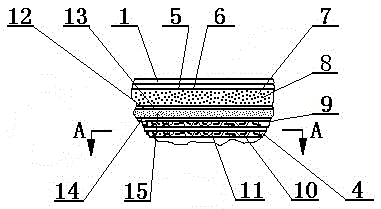

Environment-friendly and safe mouse pad with magnetic therapy function and multiple healthcare functions

InactiveCN105549772AHas a warming effectOvercoming stinging flawsInput/output processes for data processingMedicineWrist support

The invention discloses an environment-friendly and safe mouse pad with magnetic therapy function and multiple healthcare functions. The environment-friendly and safe mouse pad is characterized in that a litsea cubeba cushion layer is arranged at each of the upper part and the lower part of an inner cavity defined by a cushion layer and a base cushion layer of a wrist support; a magnetic powder cushion layer is arranged on each of the upper surface and the lower surface of the litsea cubeba cushion layer and the lower litsea cubeba cushion layer; 2-5 tea stem mixed cushion layers which are overlapped orderly are arranged between each upper magnetic powder cushion layer and the corresponding lower magnetic powder cushion layer; each litsea cubeba cushion layer is made of an upper cotton cloth layer, a lower cotton cloth layer and litsea cubeba; each magnetic powder cushion layer is made of an upper lint layer, a lower lint layer and magnetic powder; the magnetic powder is uniformly scattered on the lint surfaces, which are oppositely adhered, of the upper lint layers and the lower lint layers; each tea stem mixed cushion layer is made of arenga engleri beccari filaments, tea stems and pure cotton filaments. The environment-friendly and safe mouse pad disclosed by the invention has the magnetic therapy function and multiple healthcare functions, is environment-friendly and safe, can purify the air around the mouse pad and improve the air quality around the mouse pad, so as to satisfy the high-quality life requirement of modern people.

Owner:罗云

A kind of method of whole ecological vertical cultivation dendrobium officinale

ActiveCN104885731BFully release the wildness of original growthGuaranteed stabilityPlant cultivationCultivating equipmentsHigh densityGreenhouse

The invention discloses a full-ecological vertical cultivation method for dendrobium officinale. The cultivation method comprises the following steps of: selecting planting materials; selecting arenga engleri ropes for binding arenga engleri sheets; selecting the dendrobium officinale; selecting spring water; a planting process: moving pines arranged in matrixes into pits in a leveled greenhouse at intervals of 1.5 m, filling and leveling up the pits with soil, wrapping two-year-old dendrobium officinale domestication seedlings in a bottom-up manner from the bottoms of the pines, and fixing the seedlings on the pines; exposing stems, planting a second circle of the dendrobium officinale domestication seedlings at vertical intervals of 20 cm in a bottom-up manner, and then planting the rest seedlings in the same manner. The full-ecological vertical cultivation method has the beneficial effects that a full-ecological vertical cultivation mode is adopted, the original wild growth strength of the dendrobium officinale is fully released, under the artificial large-area cultivation conditions by modern facilities, the dendrobium officinale can grow mostly close to the wild state, organic production is realized in the whole process and the organic standards are wholly met; in addition, the stability of variety inheritance of the dendrobium officinale can be ensured and the probability of mutation is reduced so as to guarantee pure and good-quality varieties; furthermore, the greenhouse space can be fully utilized for realizing vertical space high-density cultivation and increasing the yield per mu.

Owner:HANGZHOU JIANGNANCHUNTANG BIOLOGICAL TECH

Method of seed breeding and sprout cultivating for Arenga engleri

InactiveCN1666594AReduce maintenance costsLow costClimate change adaptationCultivating equipmentsLow demandUrbanization

The invention relates to a method of processing the germination and culturing seed belonging to breeding technique of garden. With the acceleration of urbanization process, Space of plants is decreased and heat island effect is more efficient. Accordingly, the solution of the problem that how utilizes limited space to green the city and select suitable garden to plant is desiderated. Considering arenga engleri with scattering leaf, its utilization creates another landscape in garden. The inventive provided technique for breeding the seed of arenga engleri with scattering leaf and the method of cultivation of seedling, comprises that technique of seed harvest, dispose of seed pericarp, detailed technique of carrying out seeding, and seedling administration technique in later period, said method is easy to learn and low in cost and maintenance, In advantages of low demand for production field, waste-free of medicaments and materials, improvement of seed utilization and economizing seed cultivation time.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

Method of seed breeding and sprout cultivating for Arenga engleri

InactiveCN100334941CStrong technical production skillsEasy to learnClimate change adaptationCultivating equipmentsLow demandArenga engleri

The invention relates to a method of processing the germination and culturing seed belonging to breeding technique of garden. With the acceleration of urbanization process, Space of plants is decreased and heat island effect is more efficient. Accordingly, the solution of the problem that how utilizes limited space to green the city and select suitable garden to plant is desiderated. Considering arenga engleri with scattering leaf, its utilization creates another landscape in garden. The inventive provided technique for breeding the seed of arenga engleri with scattering leaf and the method of cultivation of seedling, comprises that technique of seed harvest, dispose of seed pericarp, detailed technique of carrying out seeding, and seedling administration technique in later period, said method is easy to learn and low in cost and maintenance, In advantages of low demand for production field, waste-free of medicaments and materials, improvement of seed utilization and economizing seed cultivation time.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

Production process and application of formed chemical fiber product

InactiveCN106757779AGood for physical and mental healthNot easy to produceUpholstery manufacturePackagingFilling materialsArenga engleri

The invention discloses a production process and application of a formed chemical fiber product. The filling materials of existing spring mattresses or beddings are mainly made from plant materials such as coconut fiber and arenga engleri fiber and are prone to resulting in loosening, corruption, insects, odors, bacteria and the like. The production process of the formed chemical fiber product comprises thoroughly mixing chemical fiber materials with different melting points at a certain proportion; putting semi-products loosened, lapped and needled by a combing machine into a drying oven, melting short chemical fibers with lower melting points to serve as a melted adhesive to bond unmelted high-temperature short chemical fibers together; discharging products from the drying oven and performing a forming process to obtain the formed chemical fiber product. The production process of the formed chemical fiber product is simple; due to the fact of being bonded together, the obtained chemical fiber product is less prone from deformation during application; by means of high-temperature sterilization, bacteria can be avoided, environmental protection can be achieved, and physical and mental health can be benefited. The obtained formed chemical fiber product can be widely applied to filling materials of various spring mattresses and beddings.

Owner:绍兴柯桥万丰针纺原料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com