Process for producing core stock of non-adhesive arenga engleri mattress and drawing machine and impurity removal machine

A production process, the technology of Jiaoshan Palm, which is applied in the production field of soft furniture, can solve the problems of immaturity, infestation or mildew, user inconvenience, etc., and achieves the effect of simple structure, convenient operation and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] A kind of production technology of rubber-free mountain palm mattress core material, comprises the following steps:

[0035] (1) Material selection: The palm bark of imported high-quality alpine wild palm trees is spun and sorted, and the palm fiber of 7 to 20 cm is selected as the main material; because the growth cycle of palm is very slow, the palm silk is taken from ten years The above shaped palm trees are imported high-quality alpine wild palm trees;

[0036] (2) Ingredient distribution ratio: the weight ratio of selected mountain palm fiber and polyester fiber is 70:30-80:20, preferably 70:30;

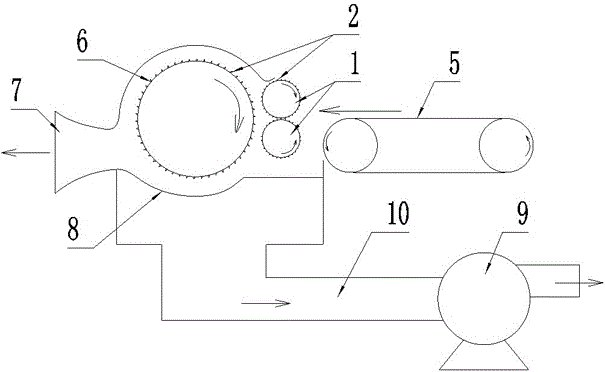

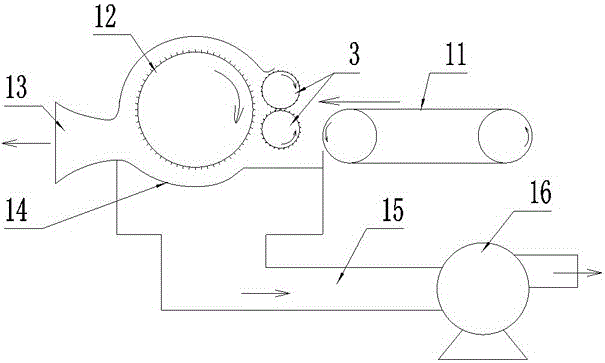

[0037] (3) Mixing and impurity removal: After the mountain palm fiber and polyester fiber are stirred evenly by the mixer, they are crimped and dust-expelled by the impurity discharger;

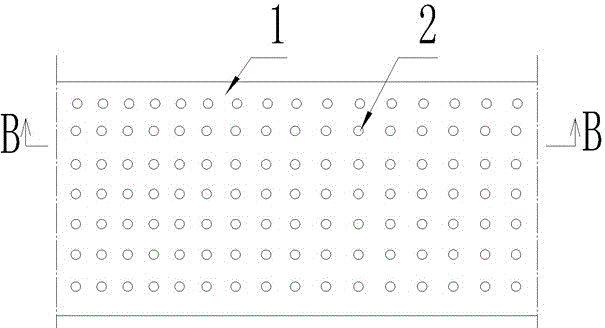

[0038] (4) Laying net: ① Pull the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com