Graphene biological diatom composite fiber as well as preparation method and application thereof

A composite fiber and graphene technology, applied in the application, fiber chemical characteristics, cellulose/protein conjugated rayon, etc., can solve the problems of insufficient wear resistance and compression resistance, and achieve good wear resistance and purification. The effect of air, low immunity prevention and auxiliary improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A graphene bio-diatom composite fiber, the graphene bio-diatom composite fiber is made of the following raw materials in parts by mass:

[0044] 40g of mountain palm and coconut palm short fiber, 20g of fine denier polyester low elastic yarn, 10g of jute bean short fiber, 10g of graphitized carbon nanofiber, 5g of bamboo charcoal short fiber, 10g of animal hair short fiber, 1g of graphene, 1g of diatomite, electric Stone powder 1g, cellulose fiber 5g, lignocellulose fiber 10g, fine cellulose fiber 10g, high-shrinkage polyester fully drawn yarn 20g and surfactant 2g.

[0045] Wherein, the fiber diameter of the cellulose fiber is 15 nanometers.

[0046] Wherein, the fiber diameter of the graphitized carbon nanofibers ranges from 20 to 100 nanometers.

[0047] Wherein, the surfactant is lauroyl glutamic acid, heavy alkylbenzene sulfonate and sodium lauryl sulfate.

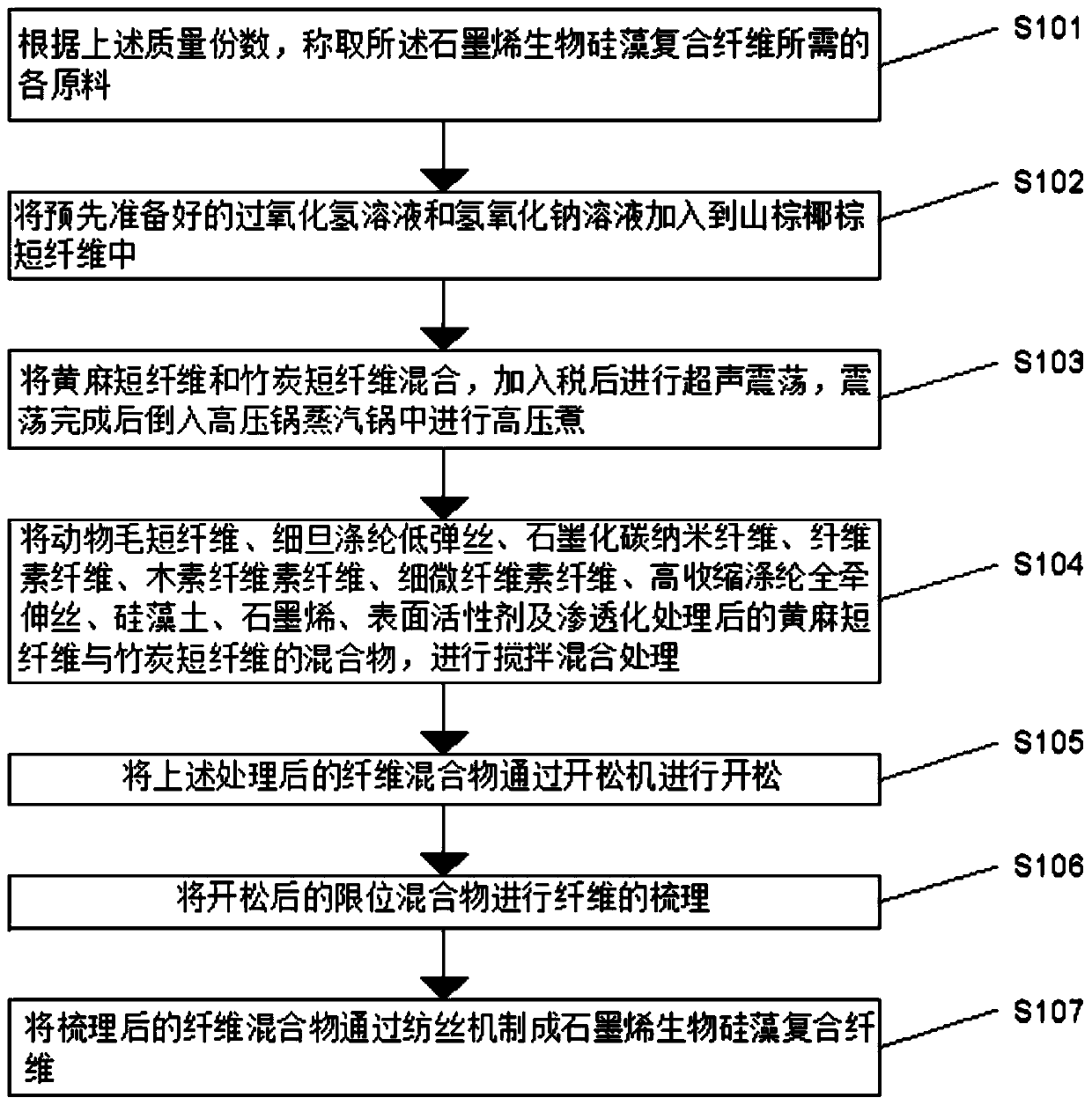

[0048] The preparation of this graphene biological diatom composite fiber comprises the following steps: ...

Embodiment 2

[0057] A graphene bio-diatom composite fiber, the graphene bio-diatom composite fiber is made of the following raw materials in parts by mass:

[0058] 45g of mountain palm and coconut palm short fiber, 25g of fine denier polyester low elastic yarn, 15g of jute bean short fiber, 15g of graphitized carbon nanofiber, 7.5g of bamboo charcoal short fiber, 12.5g of animal hair short fiber, 2.5g of graphene, diatomite 5g, tourmaline powder 1.5g, cellulose fiber 7.5g, lignocellulose fiber 15g, fine cellulose fiber 12.5g, high-shrinkage polyester fully drawn yarn 25g and surfactant 5g.

[0059] Wherein, the fiber diameter of the cellulose fiber is 15 nanometers.

[0060] Wherein, the fiber diameter of the graphitized carbon nanofibers ranges from 20 to 100 nanometers.

[0061] Wherein, the surfactant is lauroyl glutamic acid, heavy alkylbenzene sulfonate and sodium lauryl sulfate.

[0062] The preparation of this graphene biological diatom composite fiber comprises the following ste...

Embodiment 3

[0071] A graphene bio-diatom composite fiber, the graphene bio-diatom composite fiber is made of the following raw materials in parts by mass:

[0072] 50g of mountain palm and coconut palm short fiber, 30g of fine denier polyester low elastic yarn, 20g of jute bean short fiber, 20g of graphitized carbon nanofiber, 10g of bamboo charcoal short fiber, 15g of animal hair short fiber, 5g of graphene, 10g of diatomaceous earth, electric Stone powder 2g, cellulose fiber 10g, lignocellulose fiber 20g, fine cellulose fiber 15g, high-shrinkage polyester fully drawn yarn 30g and surfactant 8g.

[0073] Wherein, the fiber diameter of the cellulose fiber is 15 nanometers.

[0074] Wherein, the fiber diameter of the graphitized carbon nanofibers ranges from 20 to 100 nanometers.

[0075] Wherein, the surfactant is lauroyl glutamic acid, heavy alkylbenzene sulfonate and sodium lauryl sulfate.

[0076] The preparation of this graphene biological diatom composite fiber comprises the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com