Preparation method and application of a highly elastic layered graphene oxide composite airgel

A graphene composite and high-elasticity technology, applied in airgel preparation, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of low ozone catalytic ability, graphene oxide airgel compressibility and low elasticity and other problems, to achieve strong ozone catalytic ability, improve adsorption effect, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

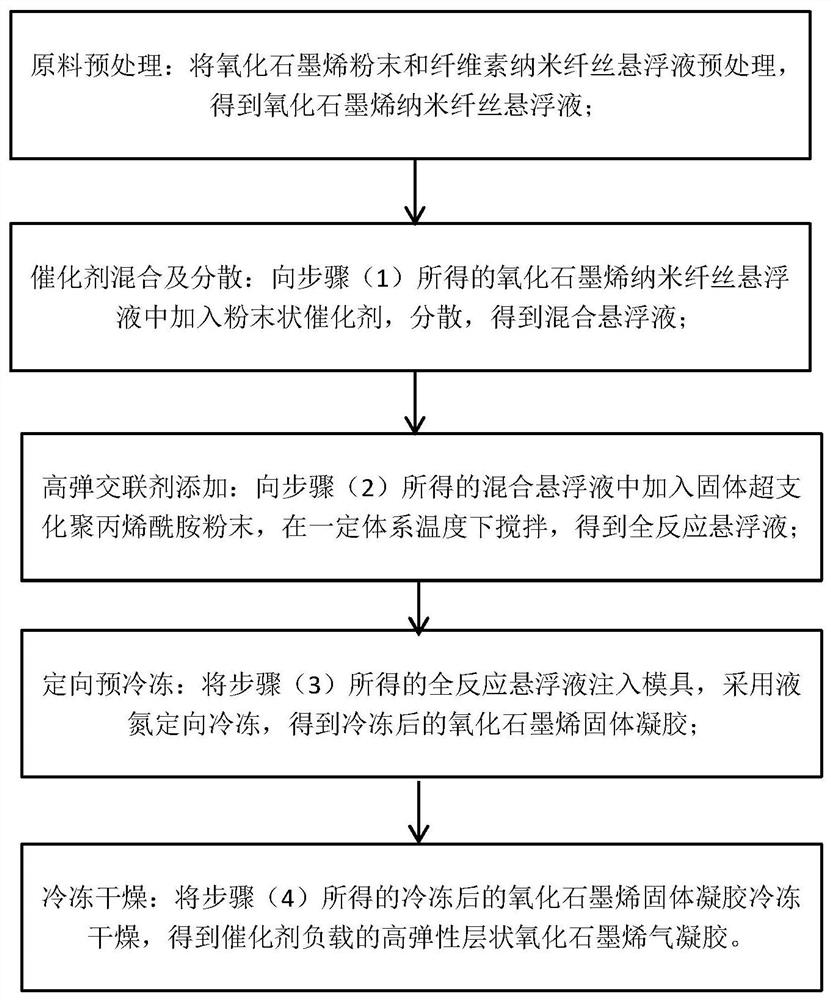

[0038] A kind of preparation method of highly elastic layered graphene oxide composite airgel of the present embodiment, the specific preparation steps are as follows:

[0039] (1) Mixing and dispersion of raw materials: Use a high-speed emulsifier to disperse graphene oxide powder in a cellulose nanofibril suspension with a solid content of 1.0%, in which the amount of graphene oxide is 10wt%, and perform high-speed emulsification and dispersion at a speed greater than 5000r / min, the dispersion time is not less than 30min, to obtain graphene oxide nanofibril suspension;

[0040] (2) Ozone catalyst mixing and dispersion: Add nanoscale powdered MnO to the graphene oxide nanofibril suspension prepared in step (1) under the condition of stirring line speed of 25m / s 2 / γ-Al 2 o 3 / TiO 2 Composite catalyst, dispersed for at least 30min, to obtain a mixed suspension; wherein, nano-scale powdery MnO 2 / γ-Al 2 o 3 / TiO2 The consumption of composite catalyst is 8.0% of graphene o...

Embodiment 2

[0047] A kind of preparation method of highly elastic layered graphene oxide composite airgel of the present embodiment, the specific preparation steps are as follows:

[0048] (1) Mixing and dispersion of raw materials: Use a high-speed emulsifier to disperse the graphene oxide powder in the cellulose nanofibril suspension with a solid content of 1.0%, in which the amount of graphene oxide is 15wt%, and carry out high-speed emulsification and dispersion at a speed greater than 5000r / min, the dispersion time is not less than 30min, to obtain graphene oxide nanofibril suspension;

[0049] (2) Ozone catalyst mixing and dispersion: Add nanoscale powdered MnO to the graphene oxide nanofibril suspension prepared in step (1) under the condition of stirring line speed of 25m / s 2 / γ-Al 2 o 3 / TiO 2 Composite catalyst, dispersed for at least 30min, to obtain a mixed suspension; wherein, nano-scale powdery MnO 2 / γ-Al 2 o 3 / TiO 2 The consumption of composite catalyst is 9.0% of ...

Embodiment 3

[0055] A kind of preparation method of highly elastic layered graphene oxide composite airgel of the present embodiment, the specific preparation steps are as follows:

[0056] (1) Mixing and dispersion of raw materials: Use a high-speed emulsifier to disperse the graphene oxide powder in the cellulose nanofibril suspension with a solid content of 1.0%, in which the amount of graphene oxide is 20wt%, and carry out high-speed emulsification and dispersion at a speed greater than 5000r / min, the dispersion time is not less than 30min, to obtain graphene oxide nanofibril suspension;

[0057] (2) Ozone catalyst mixing and dispersion: Add nanoscale powdered MnO to the graphene oxide nanofibril suspension prepared in step (1) under the condition of stirring line speed of 25m / s 2 / γ-Al 2 o 3 / TiO 2 Composite catalyst, dispersed for at least 30min, to obtain a mixed suspension; wherein, nano-scale powdery MnO 2 / γ-Al 2 o 3 / TiO 2 The consumption of composite catalyst is 10% of g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com