Carpet cleaner

A carpet cleaning machine and fixing frame technology, which is applied to cleaning equipment, vacuum cleaners, household appliances, etc., can solve the problems of cumbersome assembly, difficult assembly and arrangement, and inability to disassemble, and achieves easy and convenient disassembly process, easy and convenient installation process, The effect of reducing distance and height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

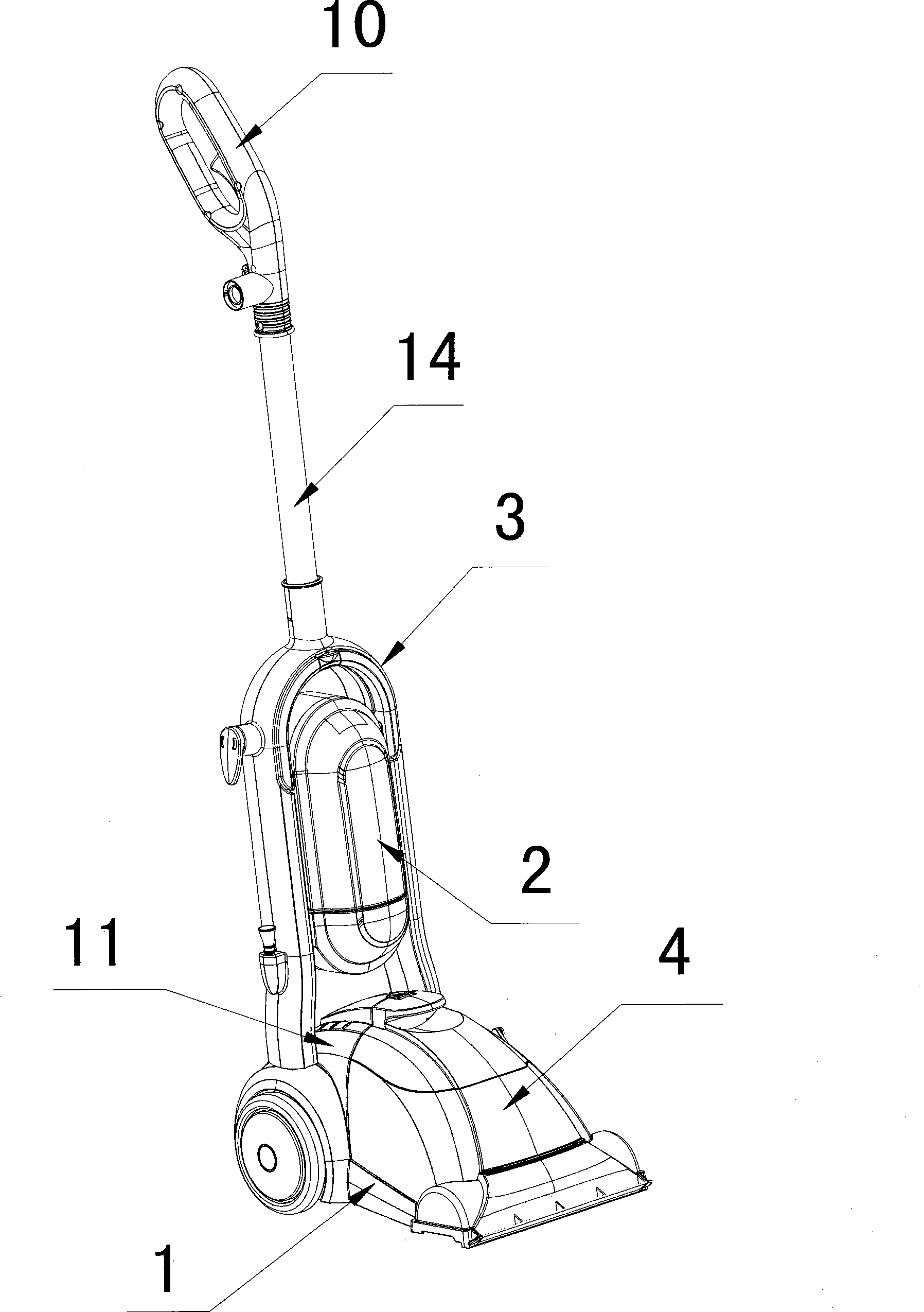

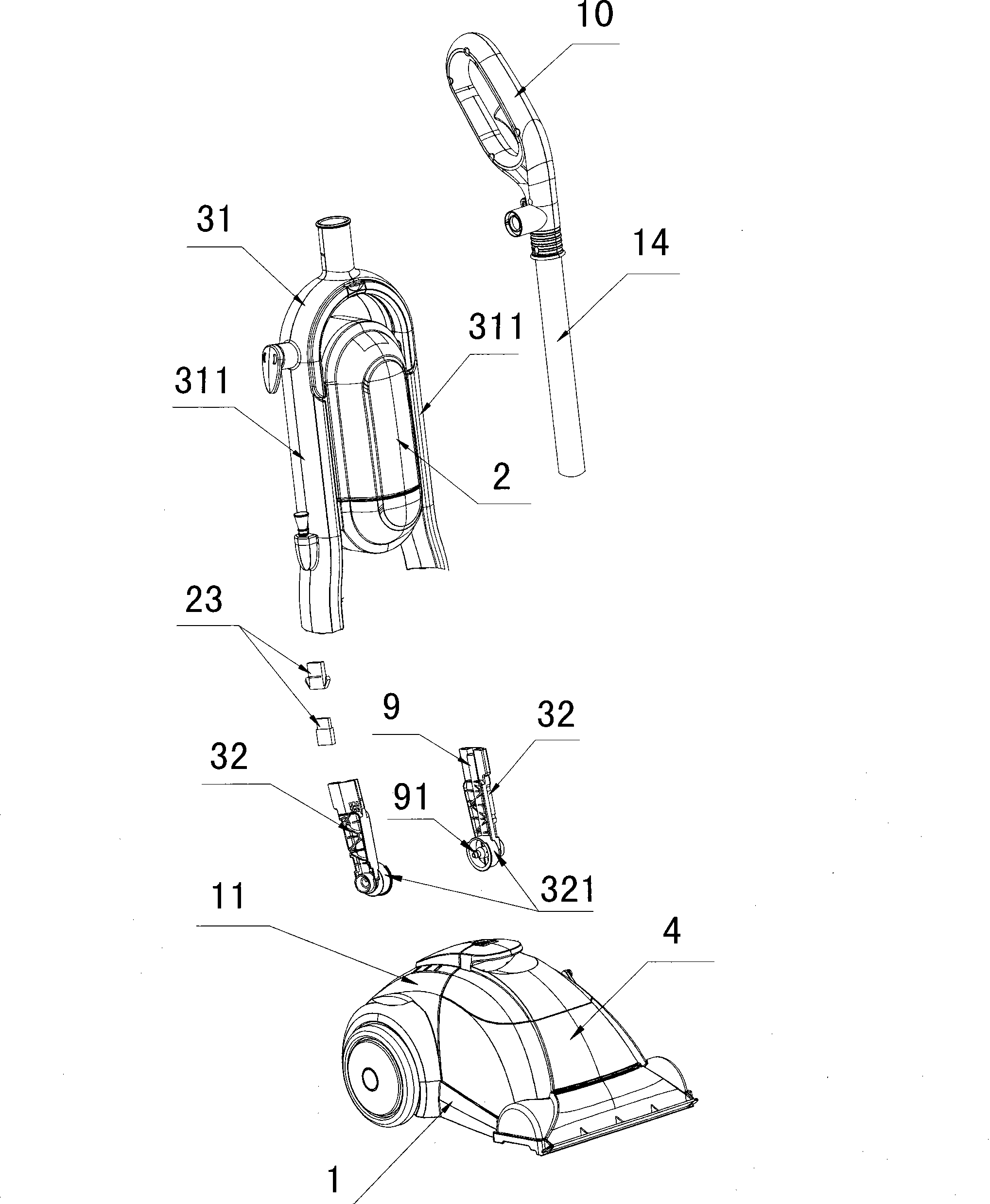

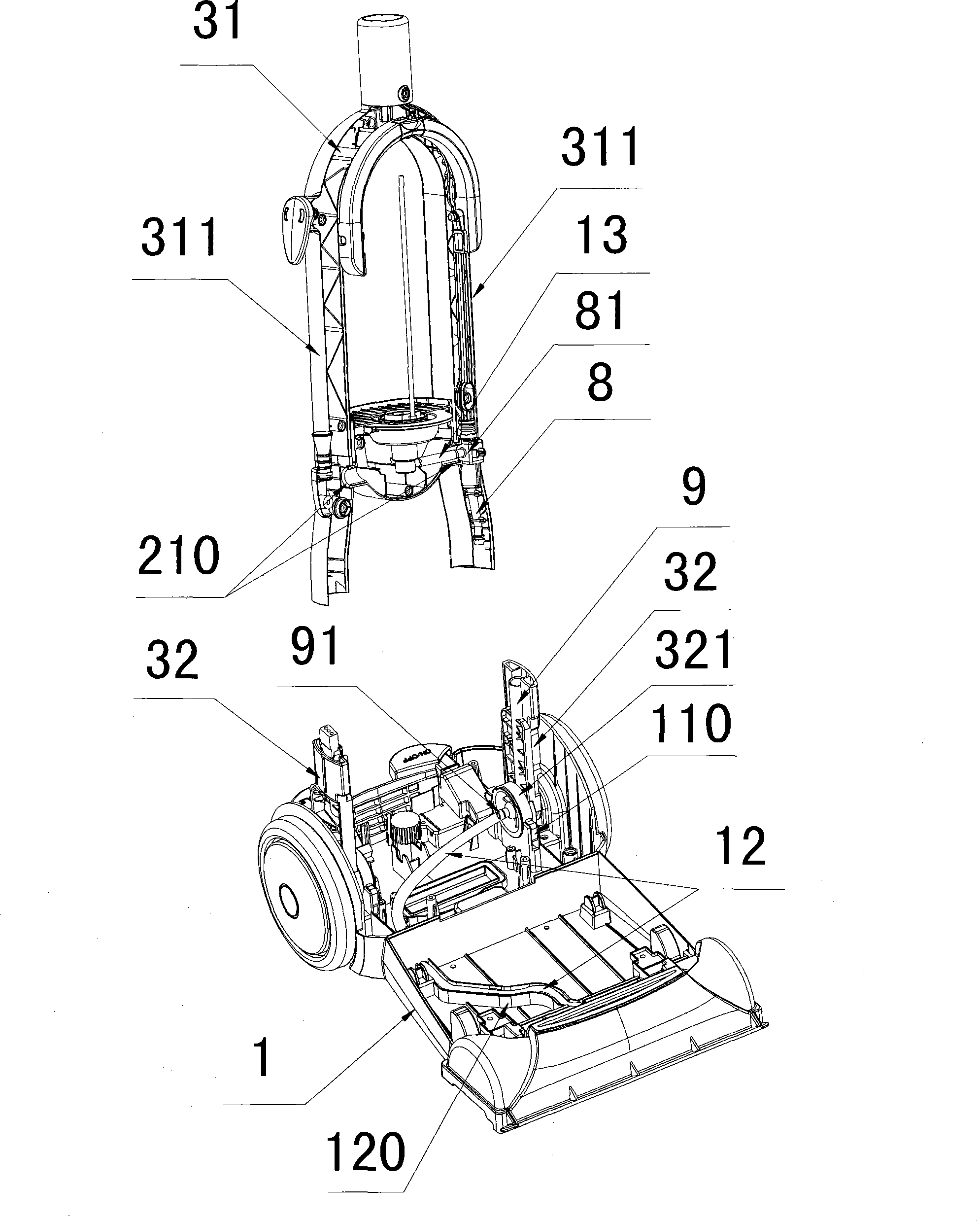

[0040] Example: Combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 Shown is a specific embodiment of the carpet cleaning machine of the present invention.

[0041] first as figure 1 As shown, the carpet cleaning machine in this embodiment is mainly composed of ground brush holder 1, water tank 2, water tank fixing frame 3, recovery box 4, control handle 10, vacuum suction machine 11 and connecting rod 14; wherein recovery box 4 and The vacuum suction machine 11 is installed on the ground brush base 1, and the recovery box 4 is positioned at the front portion of the vacuum suction machine 11; the water tank fixing frame 3 is connected on the ground brush base 1 and fixes the water tank 2 thereon; On the water tank fixing frame 3 , the joystick 10 is then fixed on the connecting rod 14 and is electrically connected with the vacuum suction machine 11 . The user can control the operation and shutdown of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com