Steel mesh enhanced anti-theft glass fibre and magnesium sheet and manufacturing process thereof

A technology of glass magnesium thin plate and glass magnesium board, which is applied in lamination devices, building materials, lamination, etc., can solve the problems of insufficient strength and insufficient strength to meet the requirements, and achieve increased strength, high production efficiency, and improved strength and the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

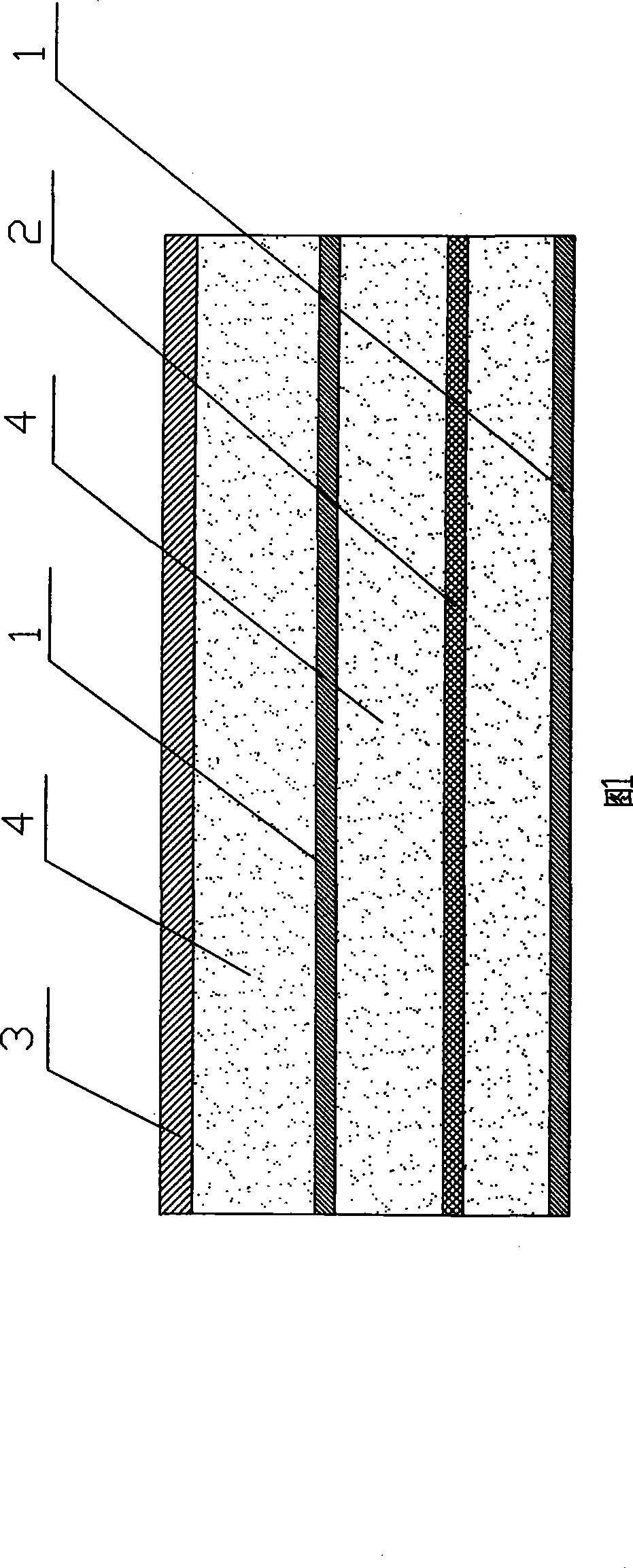

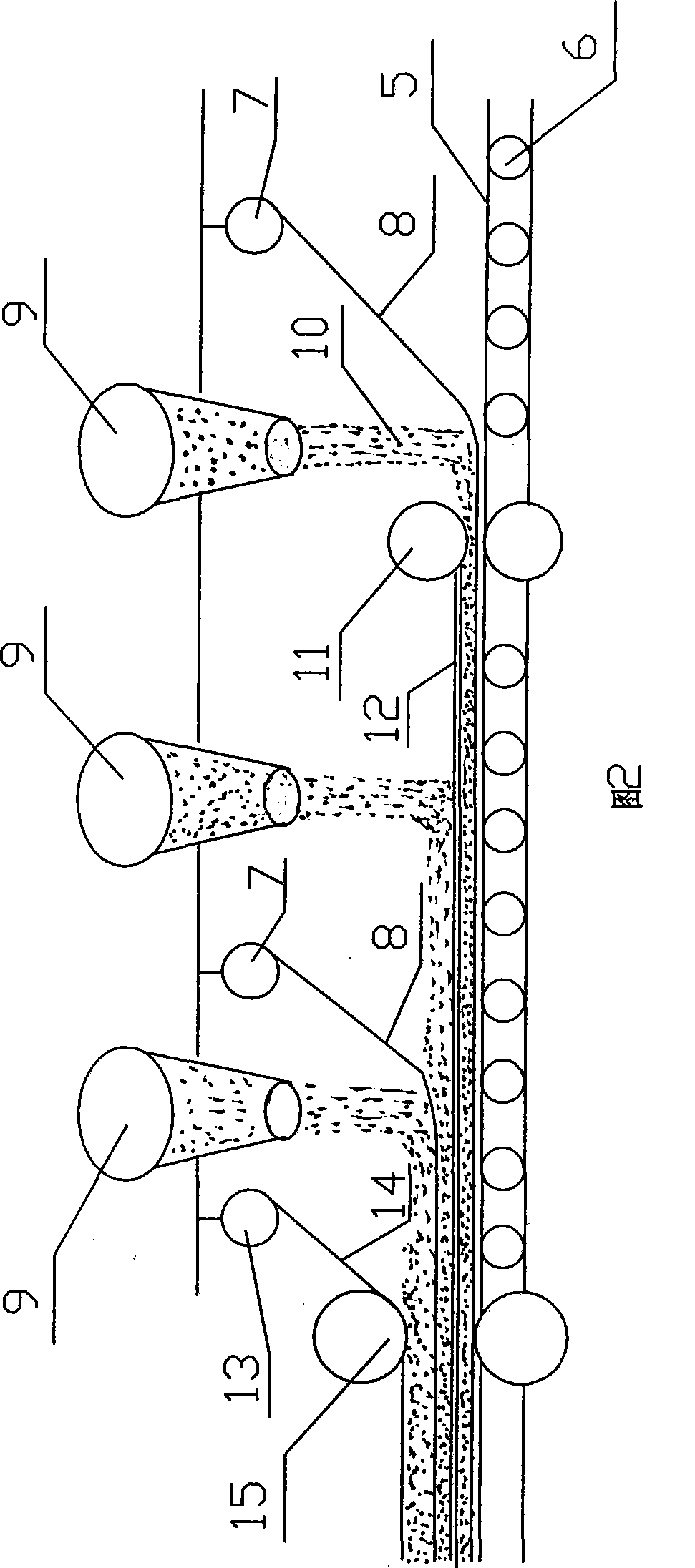

[0022] Using a width of 1.3 meters, specifications 8 × 8 (mm) or 7 × 5 (mm) glass fiber cloth

[0023] Wire mesh: φ3mm, 50×70(mm) square holes

[0024] The thickness of the steel mesh reinforced anti-theft glass magnesium sheet made according to the above-mentioned method of the present invention is 12mm.

[0025] Performance test: Fire performance: GB / 8627, Class A non-combustible, fire resistance limit ≥ 3 hours.

[0026] Sound insulation performance: ≥40dB

[0027] The steel mesh-reinforced anti-theft glass magnesium sheet is used as the cladding panel, and the sandwich is made of flame-retardant paper honeycomb to make a floor slab of 120mm (thickness)×120mm (width)×300mm (length), and the bending load is 480kg / m 2 , 2 times higher than the bending load of the floor made of traditional glass magnesium board.

Embodiment 2

[0029] According to embodiment 1, adopt φ 4mm, the steel wire mesh of 50 * 70 (mm) grid makes the anti-theft glass magnesium thin plate that the steel mesh of 12mm thick strengthens, uses the anti-theft glass magnesium thin plate that this steel mesh strengthens as cladding panel, sandwich adopts resistance Combustion paper honeycomb made of 120mm (thickness) × 120mm (width) × 300mm (length) of the floor, the bending load is 480kg / m 2 The thermal resistance is 1.1W / M.K, the sound insulation performance is ≥45dB, and the density is 42kg / m 2 , and the density of the SP (steel reinforced cement) floor slab reaching the same strength is 200kg / m 2 , the bending load is 2.6 times higher than that of the floor slab made of traditional glass magnesium board, and the weight is 1 / 5 of the SP board.

Embodiment 3

[0031] According to embodiment 1, adopt φ 6mm, the steel wire mesh of 50 * 50 (mm) grid makes the anti-theft glass magnesium thin plate that the steel mesh of 12mm thick strengthens, uses the anti-theft glass magnesium thin plate that this steel mesh strengthens as cladding panel, sandwich adopts resistance 120mm (thickness) exterior wall panel made of burning paper honeycomb, with a bending load of 480kg / m 2 , sound insulation performance ≥ 45dB, density 42kg / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com