Horizontal type fixed bed reactor for producing propene with oxygen-containing compound as raw material

A horizontal fixed bed and reactor technology, which can be used in the production of hydrocarbons from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of reduced propylene selectivity, increased temperature of raw materials, etc., and achieves convenient operation, simple structure, and equipment design and manufacture. and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

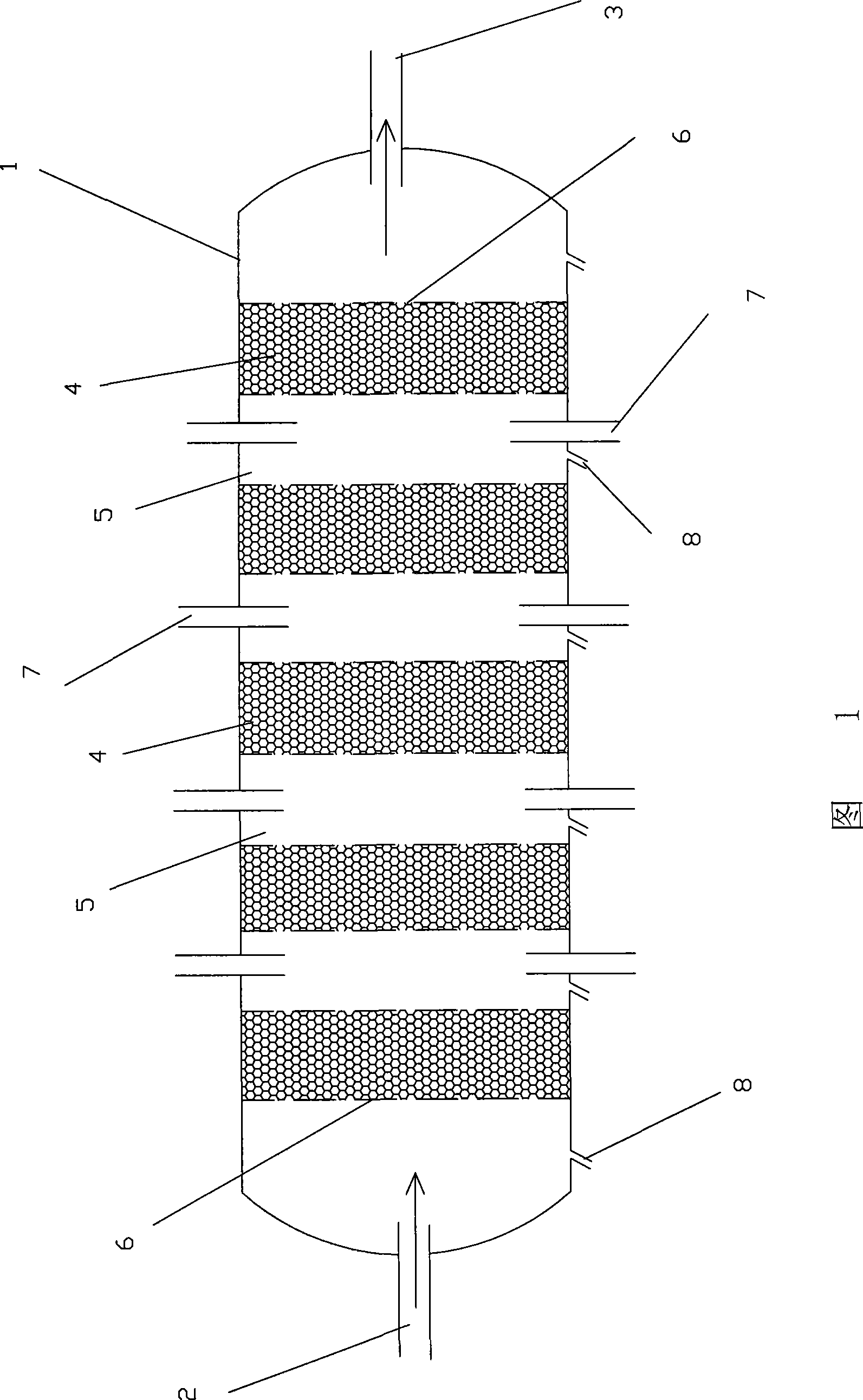

[0021] As shown in Figure 1, a kind of horizontal fixed-bed reactor that is used to produce propylene with oxygen-containing compound as raw material, comprises a horizontal cylindrical casing 1, and the cross section of casing 1 also can be other shapes, as square , ellipse, trapezoid, etc. A raw material inlet 2 is provided at one lateral end of the housing 1 , and a product outlet 3 is provided at the other end.

[0022] Housing 1 is provided with 10 porous support plates 6 horizontally arranged in parallel. The porous support plates 6 are baffles with multiple through holes on the side wall. The 10 porous support plates 6 divide the internal space of the housing 1 into 11 Areas arranged horizontally and continuously, in which the two areas located at both ends of the shell 1 communicate with the raw material inlet 2 and the raw material outlet 3 respectively, and the remaining 9 areas are 5 reaction areas 4 and 4 cooling areas 5, reaction area 4 and cooling area 5 interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com