Hub-type planetary gear two-shift automatic speed variator

An automatic transmission, planetary gear technology, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of small installation space at the drive wheel, small adaptation range, and no automatic shifting function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

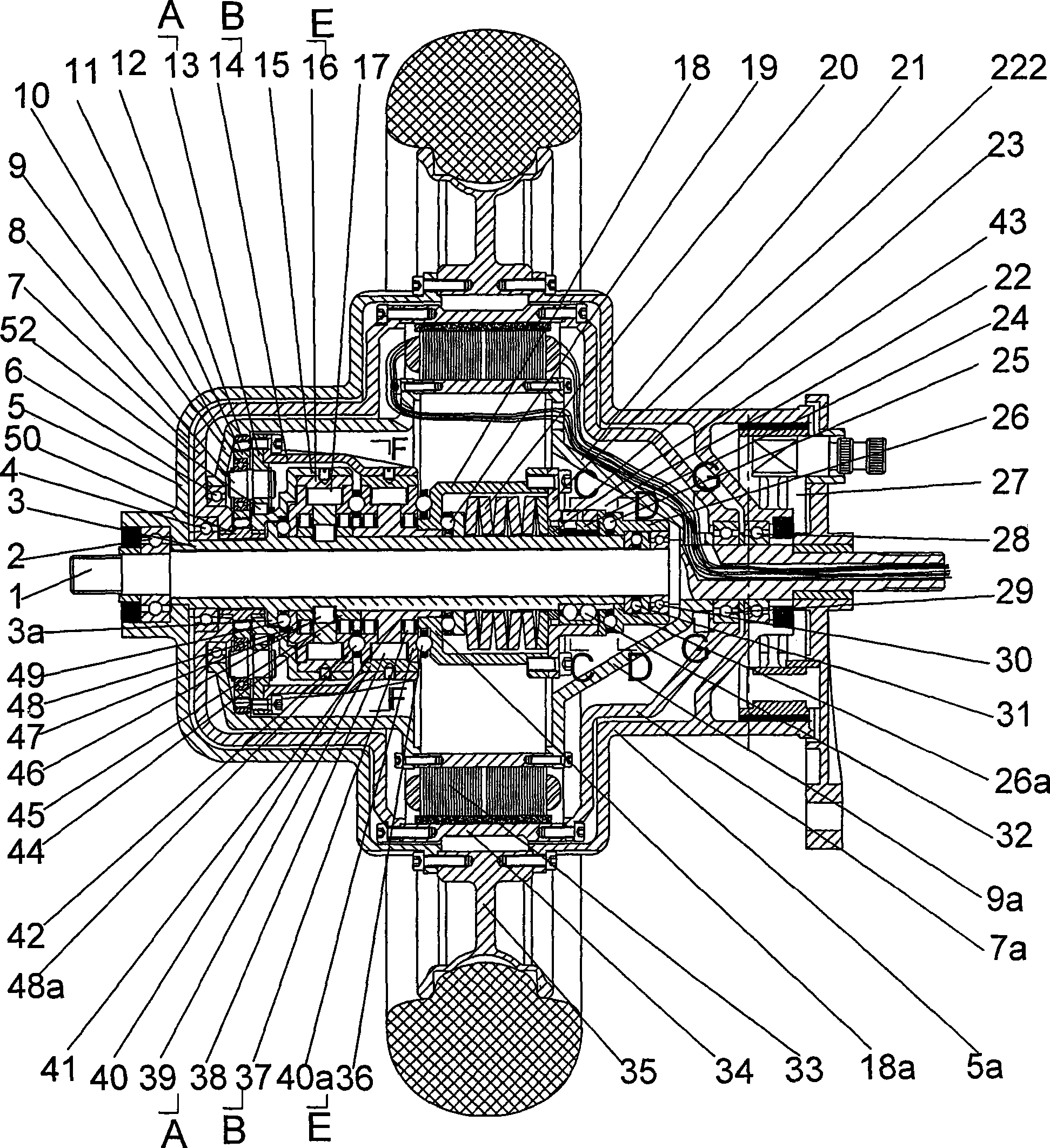

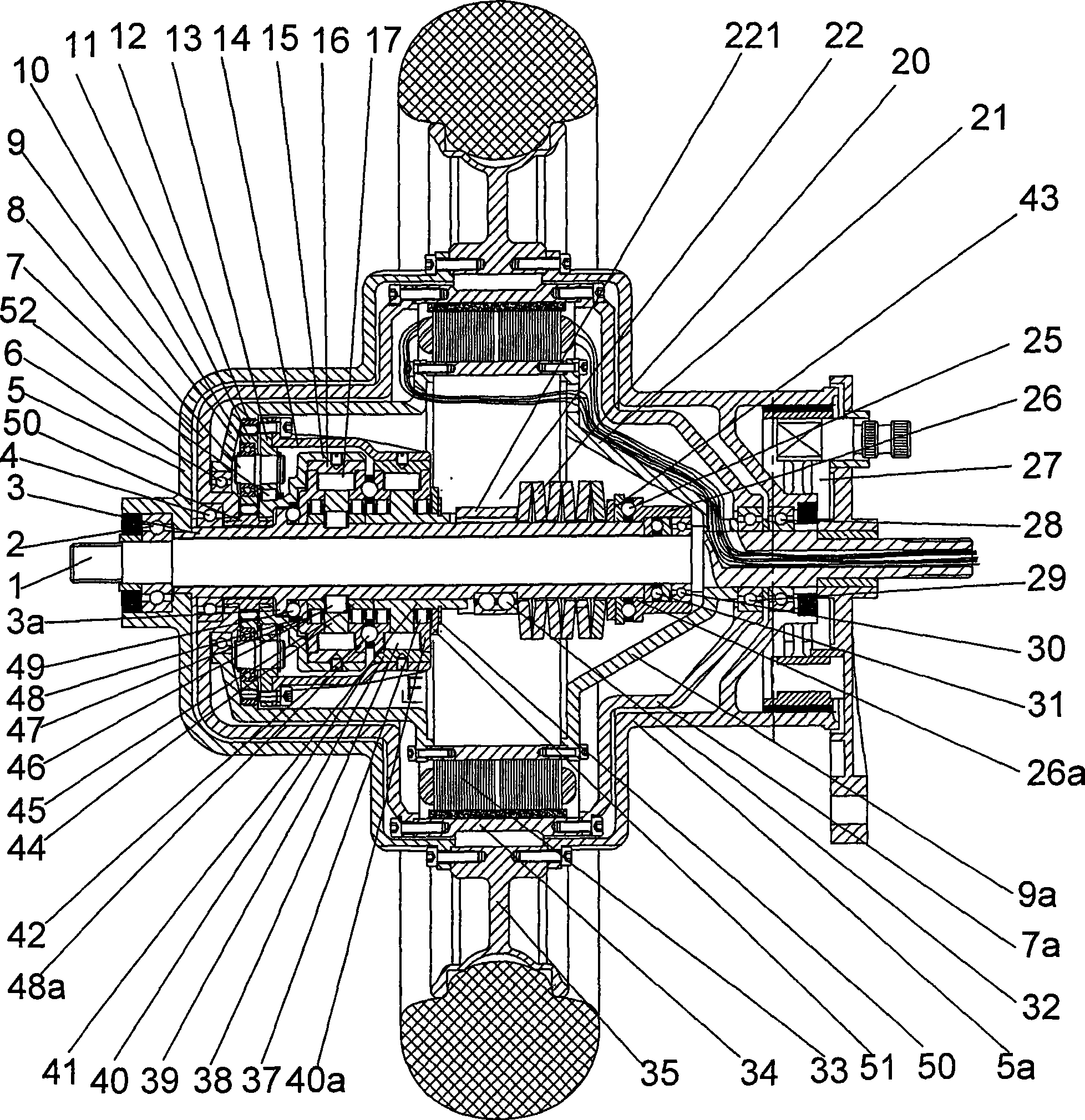

[0053] figure 1 It is a schematic diagram of the axial cross-sectional structure of the first embodiment of the present invention, as shown in the figure: the power equipment of this embodiment is a motor, which rotates clockwise when viewed from left to right during operation.

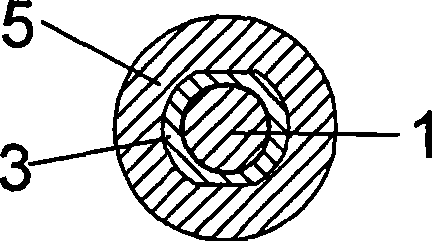

[0054] The hub-type planetary gear two-speed automatic transmission includes a motor arranged in the hub, a fixed shaft 1 fixedly connected with the motor stator 33, a transmission sleeve 3 sleeved on the fixed shaft 1 and rotatingly matched with the fixed shaft 1, and a brake device; The power output transmission sleeve 5 and the right power output transmission sleeve 5a are fixedly connected to the wheel hub cavity formed by both sides of the wheel 35. The left end of the left power output transmission sleeve 5 and the right end of the right power output transmission sleeve 5a pass through the first radial bearing 2 and the sixth radial bearing respectively. The radial bearing 28 is in rotation with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com