Wood drier

A wood drying and drying chamber technology, which is applied to local stirring dryers, dryers, dryers for stationary materials, etc. The effect of reducing organic emissions and thermal pollution, fast drying, and low exhaust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

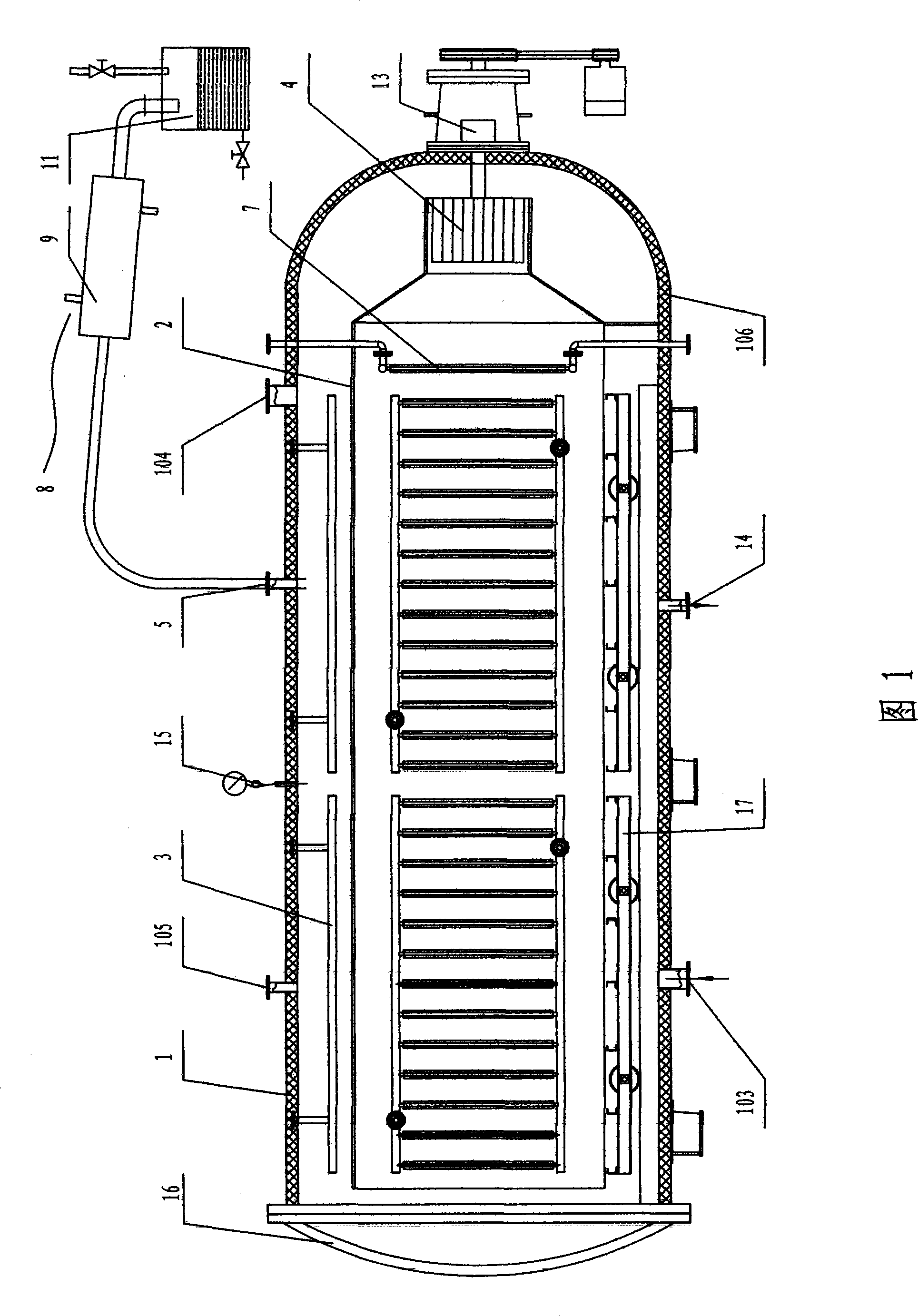

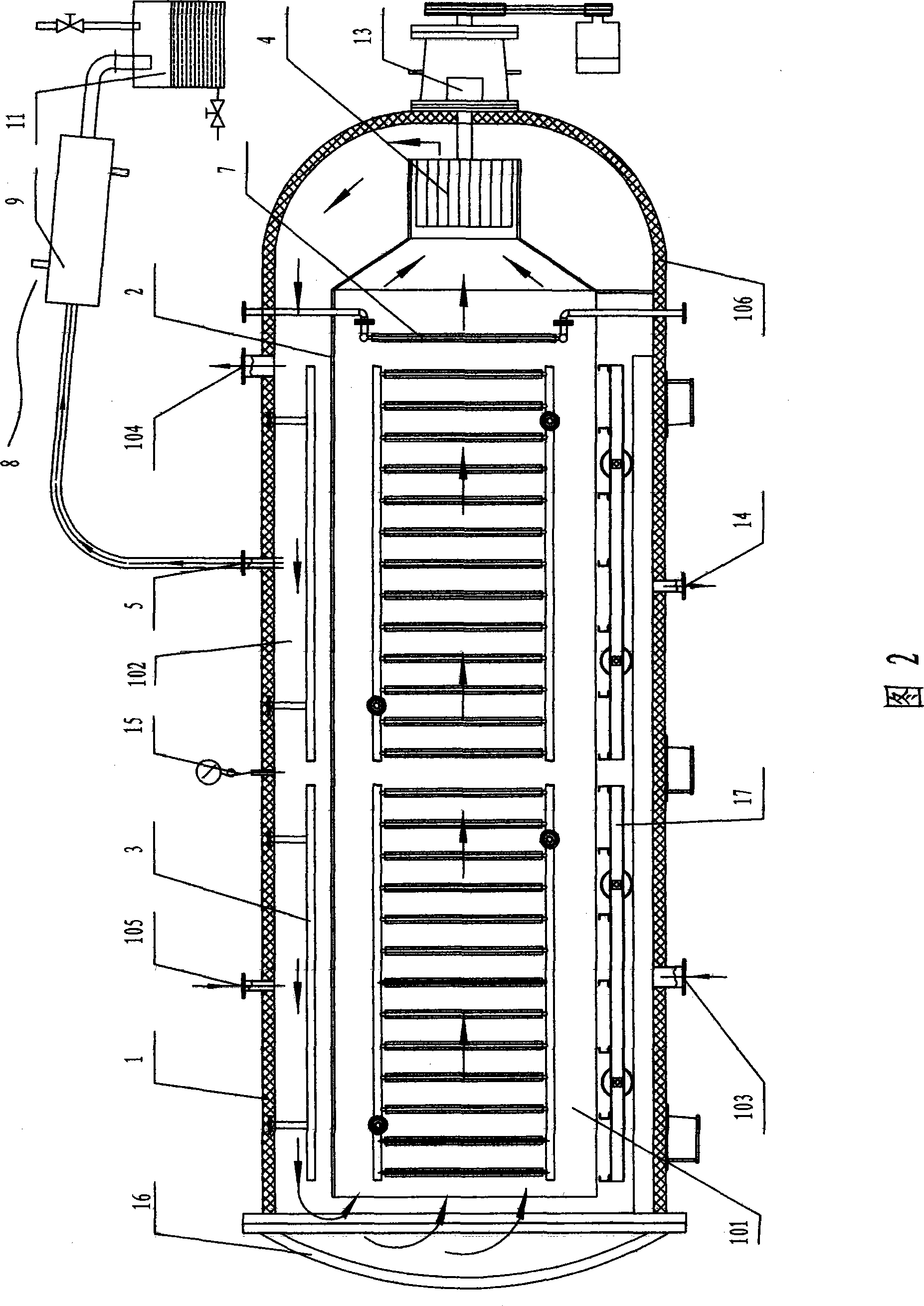

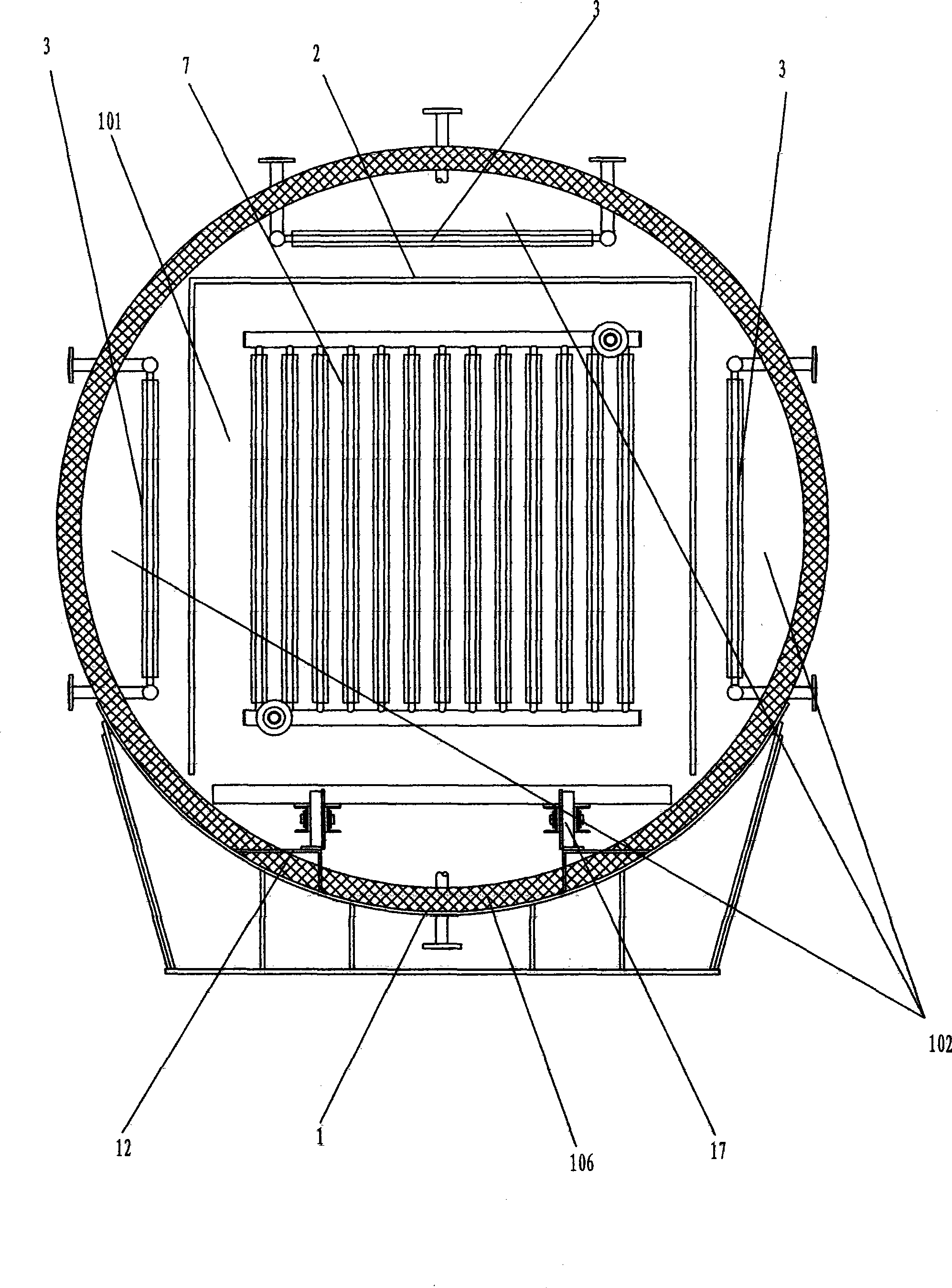

[0022] A wood drying machine, which comprises a sealed pressure vessel 1 with a door 16, and an insulation layer 106 is sandwiched in the vessel wall of the pressure vessel 1. Inside the pressure vessel 1, there is an inner partition 2 that separates the pressure vessel 1 into a drying chamber 101 and a heat exchange chamber 102 that communicate with each other. The cross section of the pressure vessel 1 is circular, and the inner partition 2 separates the pressure vessel 1. The inner chamber is divided into three arc-shaped heat exchange chambers 102 and a square drying chamber 101. A heater 3 is provided in the heat exchange chamber 102, a circulation fan 4 is provided between the drying chamber 101 and the heat exchange chamber 102, and a safety valve 5 communicating with the outside is provided on the pressure vessel 1 and cooling device 6. The cooling device 6 includes a heat exchanger 7 arranged on one side of the air inlet of the circulating fan 4, and the medium in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com