Preparation method and applications of base self-assembly based strong-toughness self-repairing adhesive hydrogel material

A hydrogel and self-assembly technology, applied in applications, pharmaceutical formulations, surgical adhesives, etc., can solve structural instability and other problems, and achieve the effects of excellent adhesion performance, large output, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a strong and tough self-repairing tissue adhesion hydrogel material based on base self-assembly, including the following steps:

[0034] S1 uses 2-acrylamide-2-methylpropanesulfonic acid, AIBN, and DMSO to react to prepare poly(2-acrylamide-2-methylpropanesulfonic acid) (PAMPS);

[0035] S2 After the prepolymer obtained in step S1 is heated to 60°C, CDI is added to react for 3 hours, and finally adenine A is added to react for 5 hours respectively, the resulting products are subjected to dialysis treatment, and the resulting products are vacuum dried at 70°C for use;

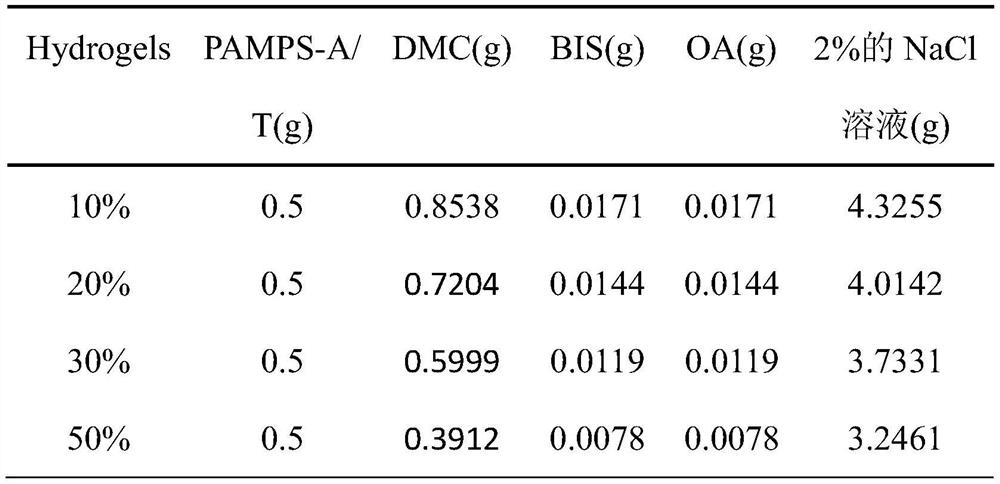

[0036] S3 Add photoinitiator and crosslinking agent to the mixed solution of polymer containing different base units, 2% NaCl solution and cationic monomer methacryloxyethyltrimethylammonium chloride obtained in step S2, and ultrasonic Dissolve it completely, let it stand for a few minutes after argon gas, and finally transfer it to the PTFE template;

[0037] S4 Place the plastic sheet on ...

Embodiment 1

[0055] Step 1: The molar mass of AIBN is 2% of the molar mass of monomer AMPS, the solvent is DMSO, and the solid content is 10%. The calculated amount of 2-acrylamide-2-methylpropanesulfonic acid and 90g DMSO are added to the three-necked flask and stirred The temperature was increased to 75°C, nitrogen was added and half of the calculated amount of AIBN was added, and the reaction was carried out for 6 hours. After 6 hours of reaction, add a quarter of the calculated amount of AIBN and react for 3 hours. After reacting for 3 hours, add the calculated amount of remaining AIBN to react for 3 hours. After the reaction is completed, the obtained poly(2-acrylamide-2-methylpropanesulfonic acid) is collected for use;

[0056] Step 2: Poly(2-acrylamide-2-methylpropanesulfonic acid): carbonyl diimidazole (CDI): A(T) is 10:1.1:1. The calculated amount of 2-acrylamide-2-methylpropanesulfonic acid solution was added to the three-necked flask, the temperature was raised to 60°C, the calcu...

Embodiment 2

[0059] Step 1: The molar mass of AIBN is 2% of the molar mass of monomer AMPS, the solvent is DMSO, and the solid content is 10%. The calculated amount of 2-acrylamide-2-methylpropanesulfonic acid and 90g DMSO are added to the three-necked flask and stirred The temperature was increased to 75°C, nitrogen was added and half of the calculated amount of AIBN was added, and the reaction was carried out for 6 hours. After 6 hours of reaction, add a quarter of the calculated amount of AIBN and react for 3 hours. After reacting for 3 hours, add the calculated amount of remaining AIBN to react for 3 hours. After the reaction is completed, the obtained poly(2-acrylamide-2-methylpropanesulfonic acid) is collected for use;

[0060] Step 2: Poly(2-acrylamide-2-methylpropanesulfonic acid): carbonyl diimidazole (CDI): A(T) is 10:2.2:2. The calculated amount of 2-acrylamide-2-methylpropanesulfonic acid solution was added to the three-necked flask, the temperature was raised to 60°C, the calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com