Method and apparatus for operating a methane-fuelled engine and treating exhaust gas with a methane oxidation catalyst

A methane oxidation and gas emission technology, applied in combustion engines, internal combustion piston engines, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as increasing the complexity of the engine, achieve low NOx and carbon dioxide emissions, easy effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

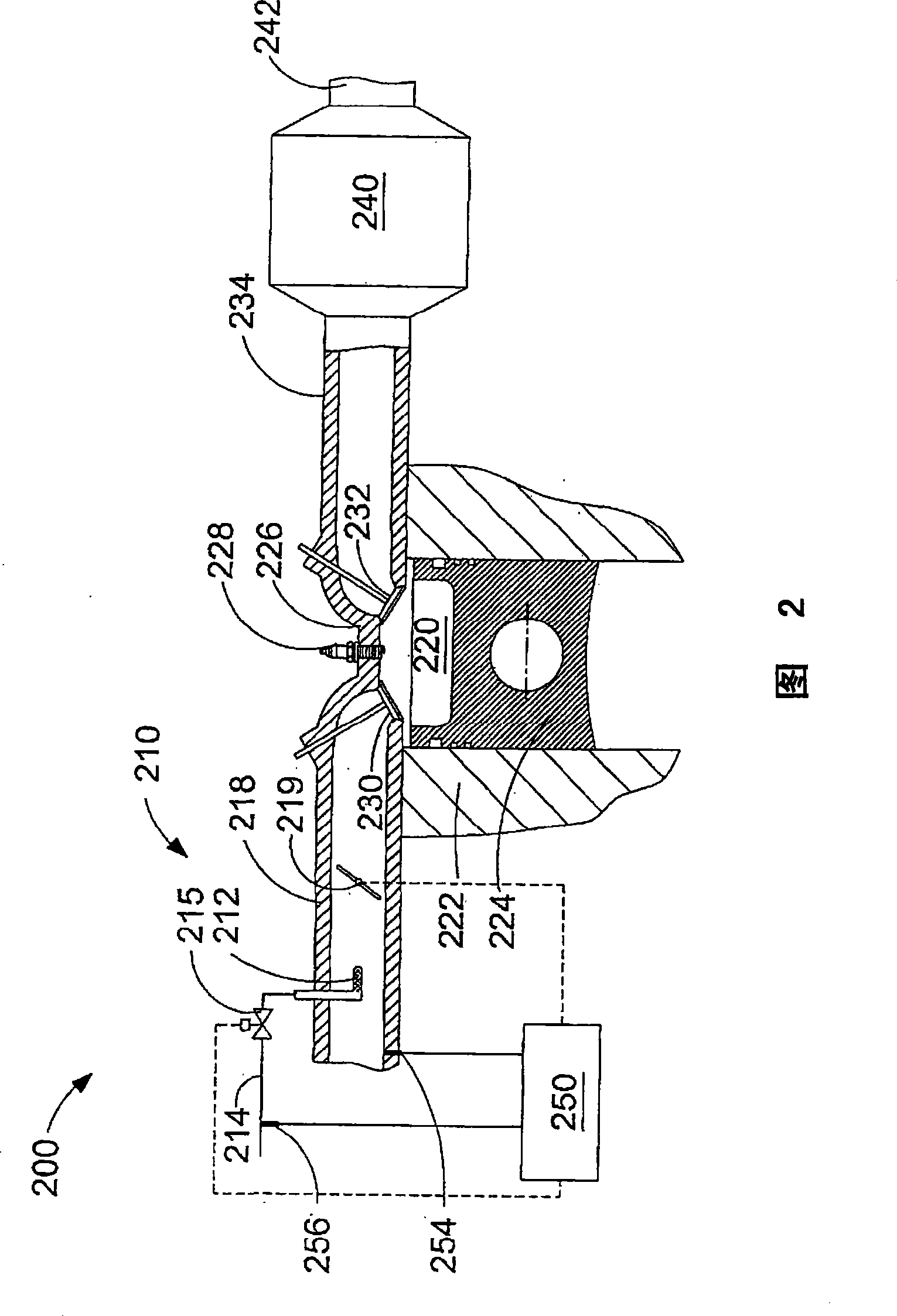

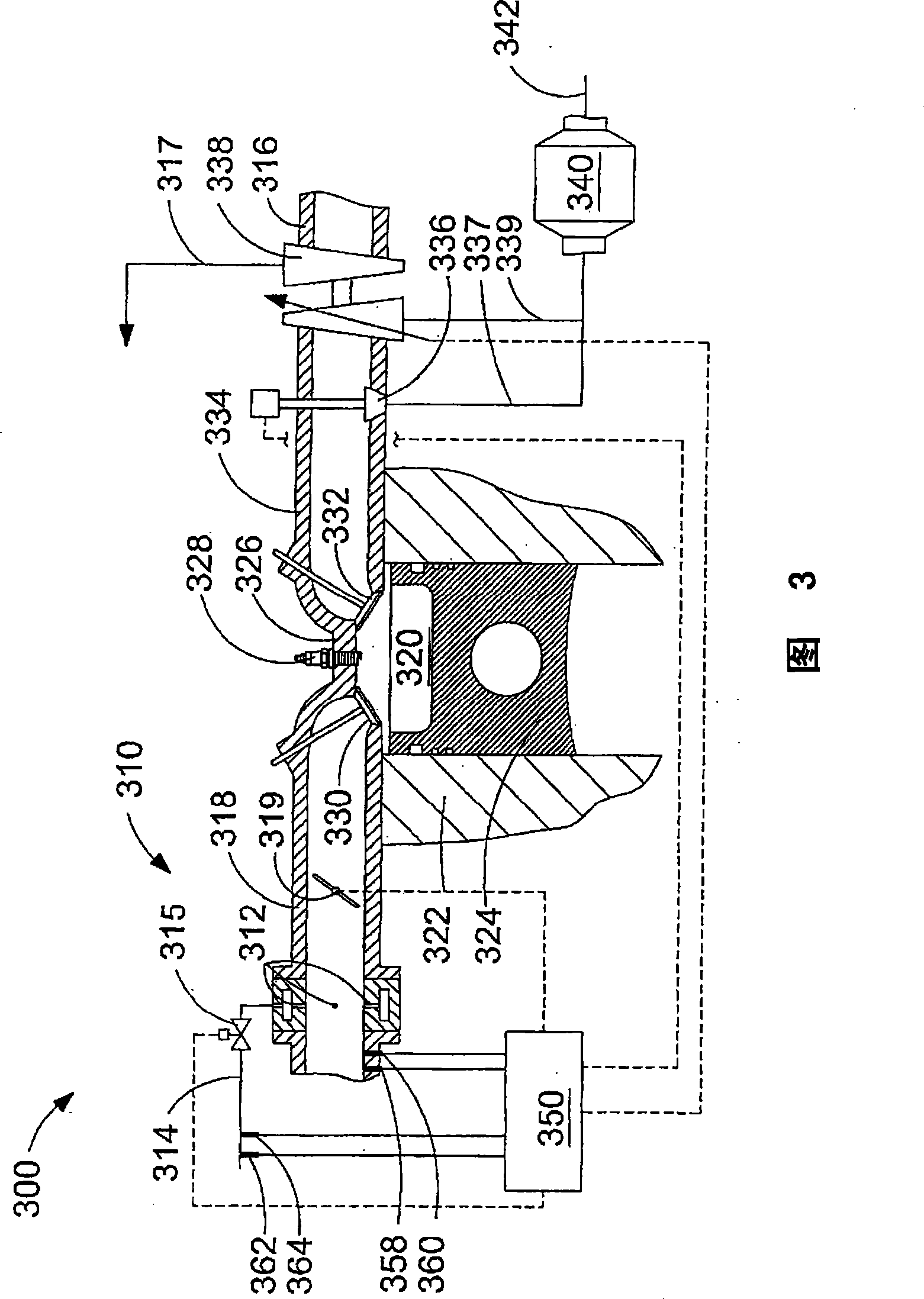

[0034] With reference to the drawings, components with similar reference numerals and similar names separated by multiples of 100 refer to similar components in different embodiments.

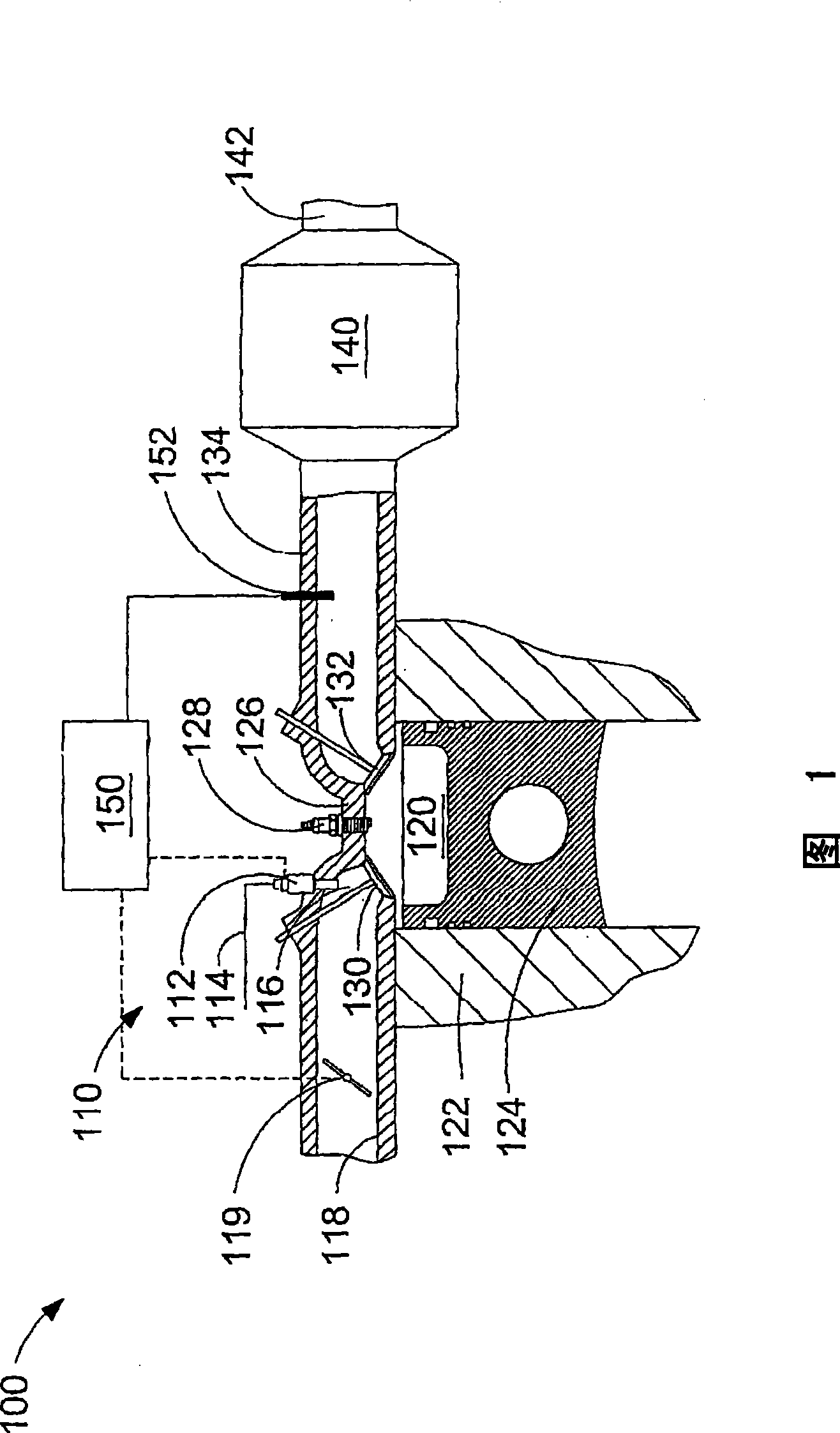

[0035] Fig. 1 is a schematic diagram of an apparatus 100 for implementing the disclosed method. The equipment includes a fuel injection system 110, an engine combustion chamber 120, a catalytic converter 140, and an electronic controller 150. In this embodiment, the fuel injection system 110 includes a port injector 112 that introduces fuel from the fuel supply pipe 114 into the intake port 116. Air flows into the combustion chamber 120 through the intake manifold 118, and the throttle valve 119 regulates the flow of air through the intake manifold 118. The combustion chamber 120 is defined by the cylinder block 122, the piston 124 and the cylinder head 126. The engine may include a spark plug 128 for triggering the ignition of the charge in the combustion chamber 120. As is known for internal comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com