Multi-tower type powder lot ozone sterilization system

An ozone sterilization and powder technology, applied in the direction of chemistry, can solve the problems of incomplete sterilization and dead ends, and achieve the effect of high sterilization efficiency, small loss and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

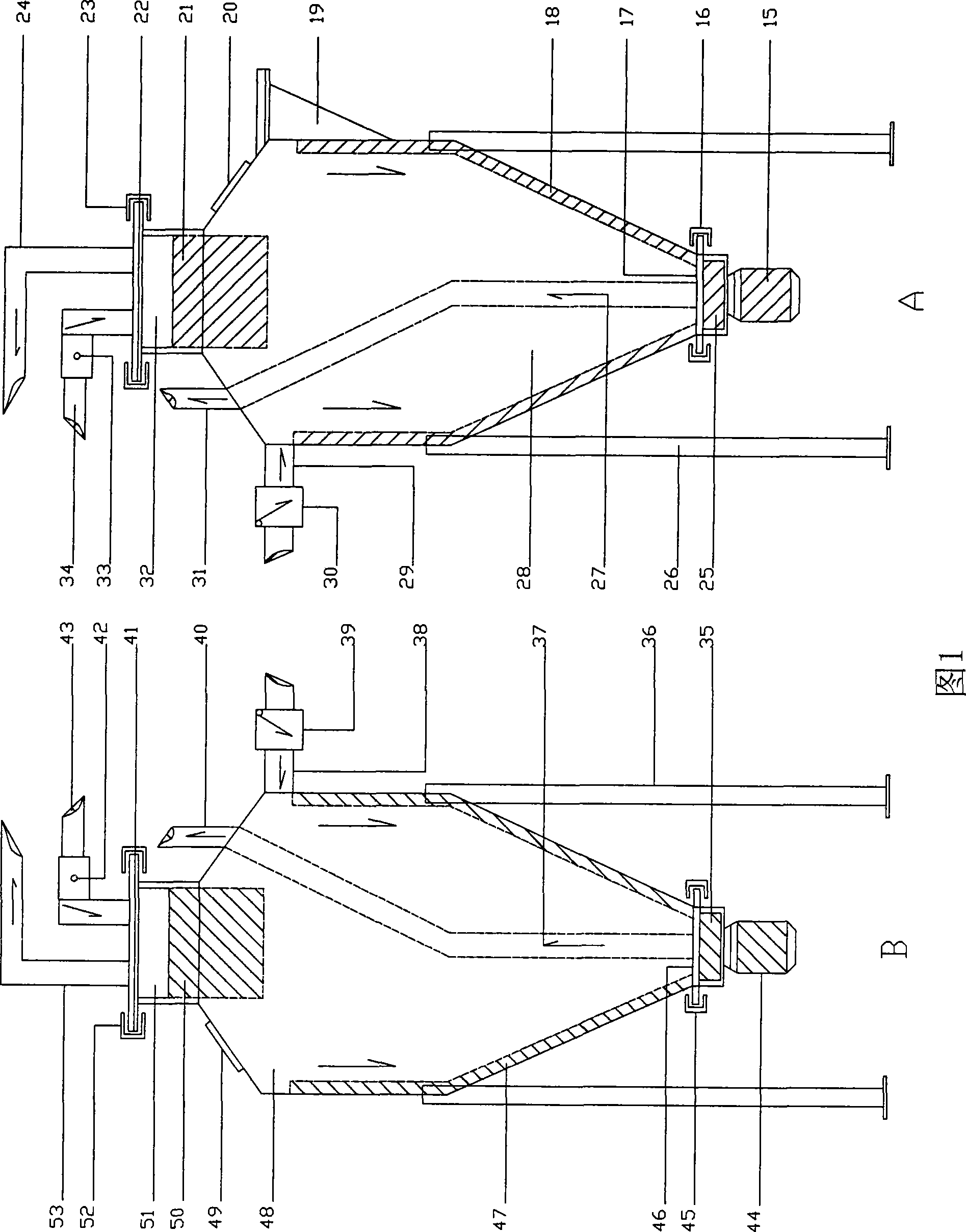

[0033] As shown in Figure 1 and 4.

[0034]A multi-tower ozone sterilization system, including an ozone generator (the same as the prior art, can be purchased directly from the market), an air supply device (composed of a fan A' and a fan B'), a first air-powder mixing The main tower 28 and the second air-powder mixing main tower 48, the ozone generator is connected with the air outlet ducts of the air supply fan A' and the fan B' through the pipeline, and the air inlet and outlet of the fan A' and the fan B' pass through the corresponding The pipeline is connected with the corresponding inlet and return ducts on the first gas-powder mixing main tower 28 (A tower) and the second gas-powder mixing main tower 48 (B tower). The powder mixing main towers 48 are directly or indirectly connected with a powder feeding pipeline and a powder returning pipeline for sending powder from one main tower to another main tower. Catalytic converter, 8 and gas cooler are installed on the outpu...

Embodiment 2

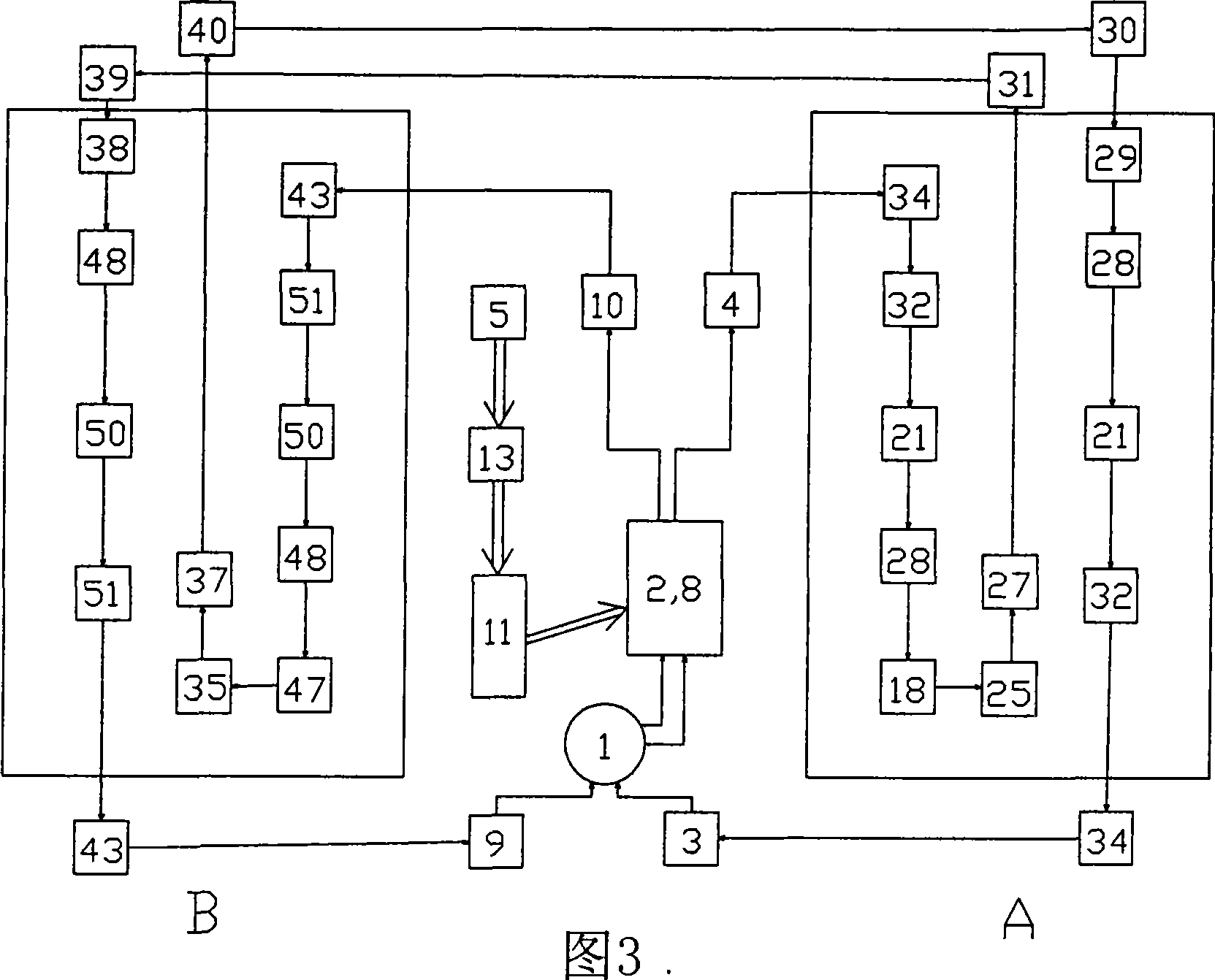

[0038] As shown in Figures 1, 3, and 5.

[0039] The difference between the present embodiment and embodiment one is only that the air supply device only uses a fan 1 (should adopt a high-pressure fan), and the layout of the fan 1, the odor generator 11 and the control valve is as follows: Figure 5 shown. By controlling the opening and closing of valves 3, 4, 9, and 10, one fan can be used to change the wind direction between the two main towers, so that the powder in one tower can be sent to the other tower and can work alternately. , compared with Embodiment 1, a fan can be omitted, but the control part is slightly more complicated.

Embodiment 3

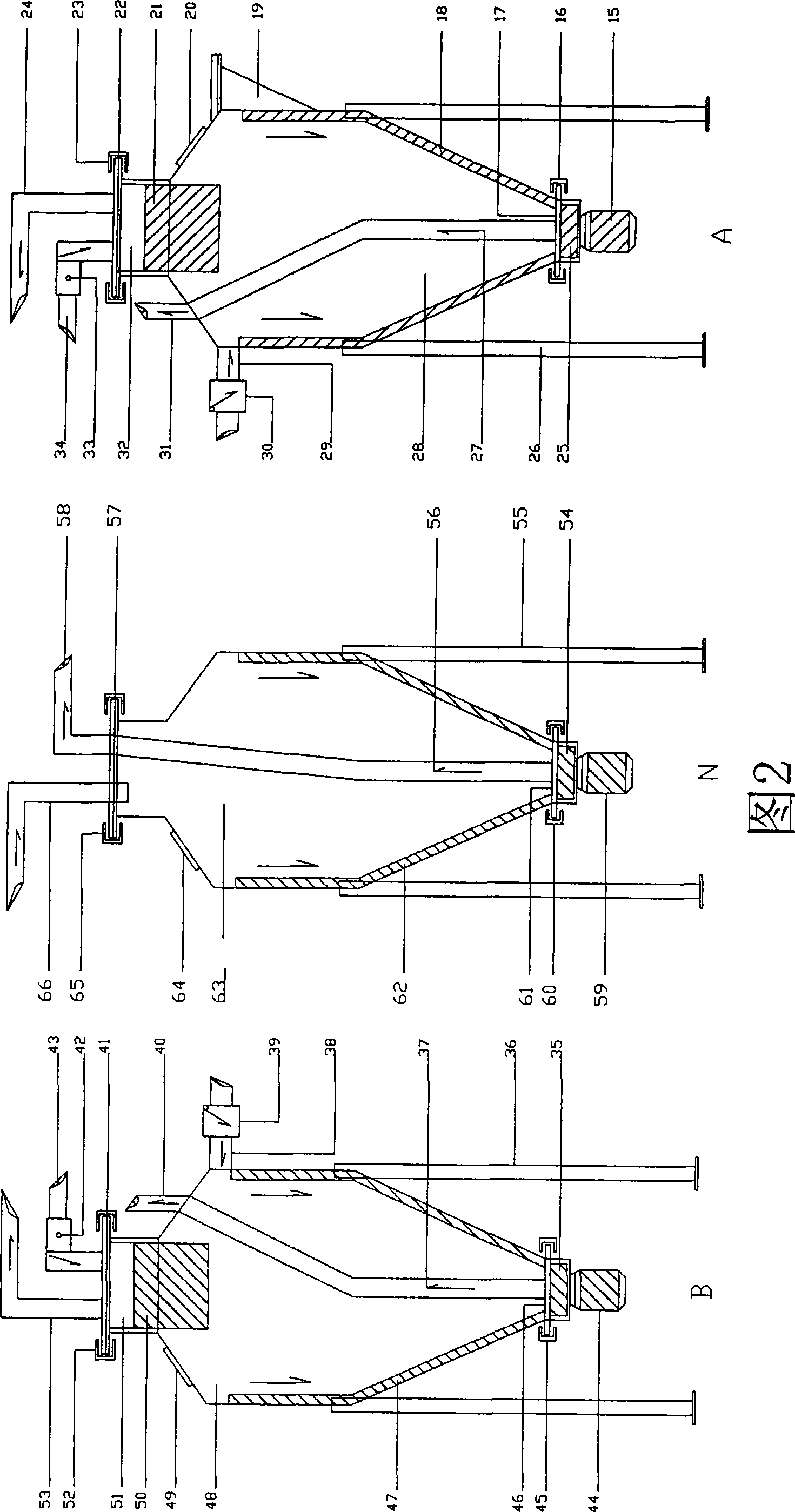

[0041] As shown in Figure 2 and 3.

[0042] The difference between this embodiment and Embodiment 1 is that an intermediate mixing tower N is connected in series between the two main towers A and B (multiple series can also be used as required) to extend the powder transportation path. , the intermediate mixing tower 63 has only powder inlet and outlet pipes, as shown in Figure 2. Specifically, the bottom of the intermediate mixing tower 63 is provided with an air powder distributor 54, an air powder input pipe 66 and an air powder output pipe 58 are installed on its upper end, and an air guide pipe 62 is installed on the tower wall to distribute the air powder. The device 54 is connected to each other with the gas powder output pipe 58 stretching out outside the tower by the suction pipe 56, and the gas powder input pipe 66 is mixed with the gas powder output pipe 58 on the adjacent intermediate mixing tower or the gas powder on the first gas powder mixing main tower. The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com