Two-channel magnetorheological damper with passage gating capability

A magnetorheological damper, dual-channel technology, applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of cumbersome design, complex structure, and difficult serialization and generalization of magnetorheological dampers. Achieve serialization and generalization, and simplify the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

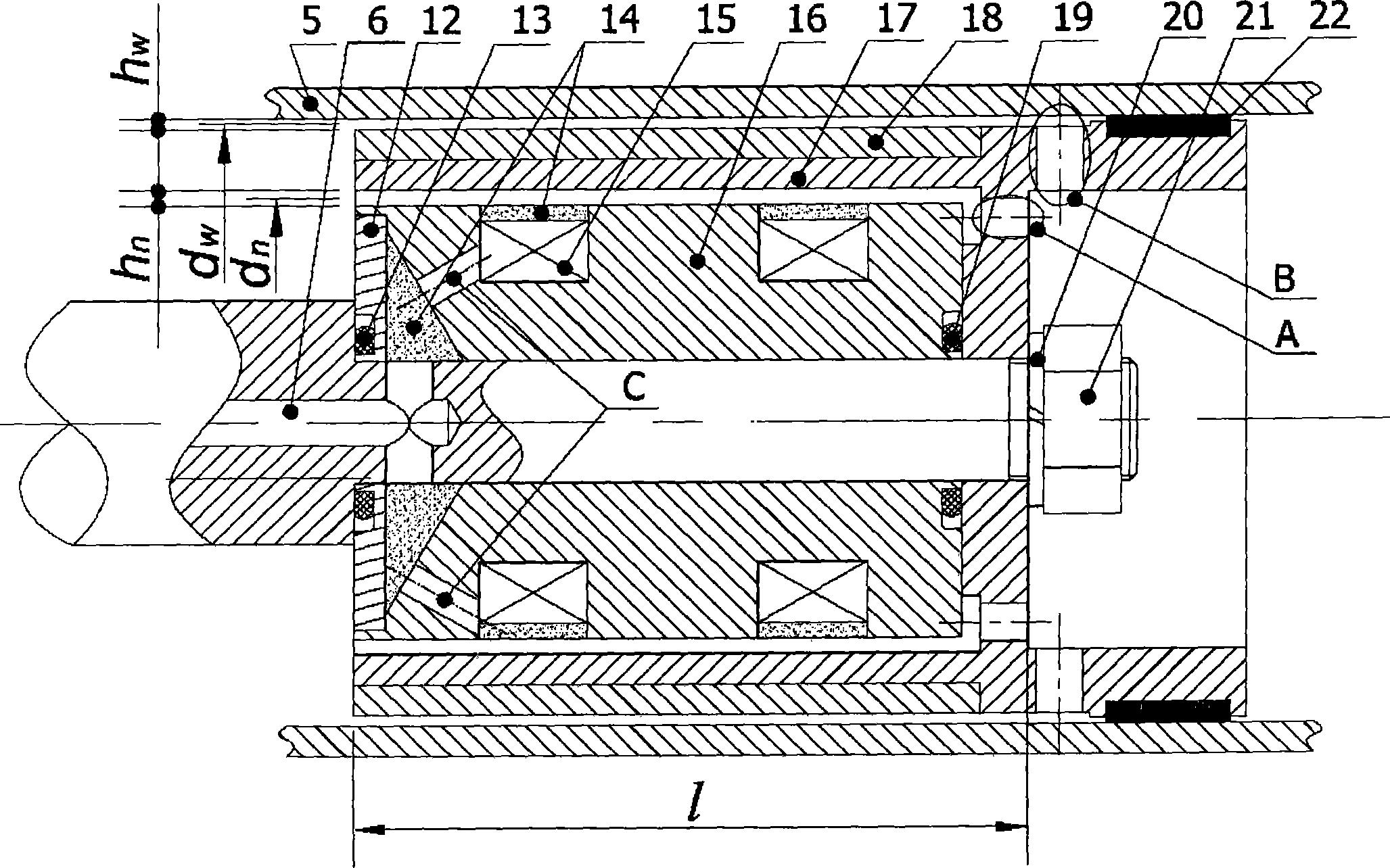

[0017] The technical solution of the present invention will be described in further detail below according to the accompanying drawings.

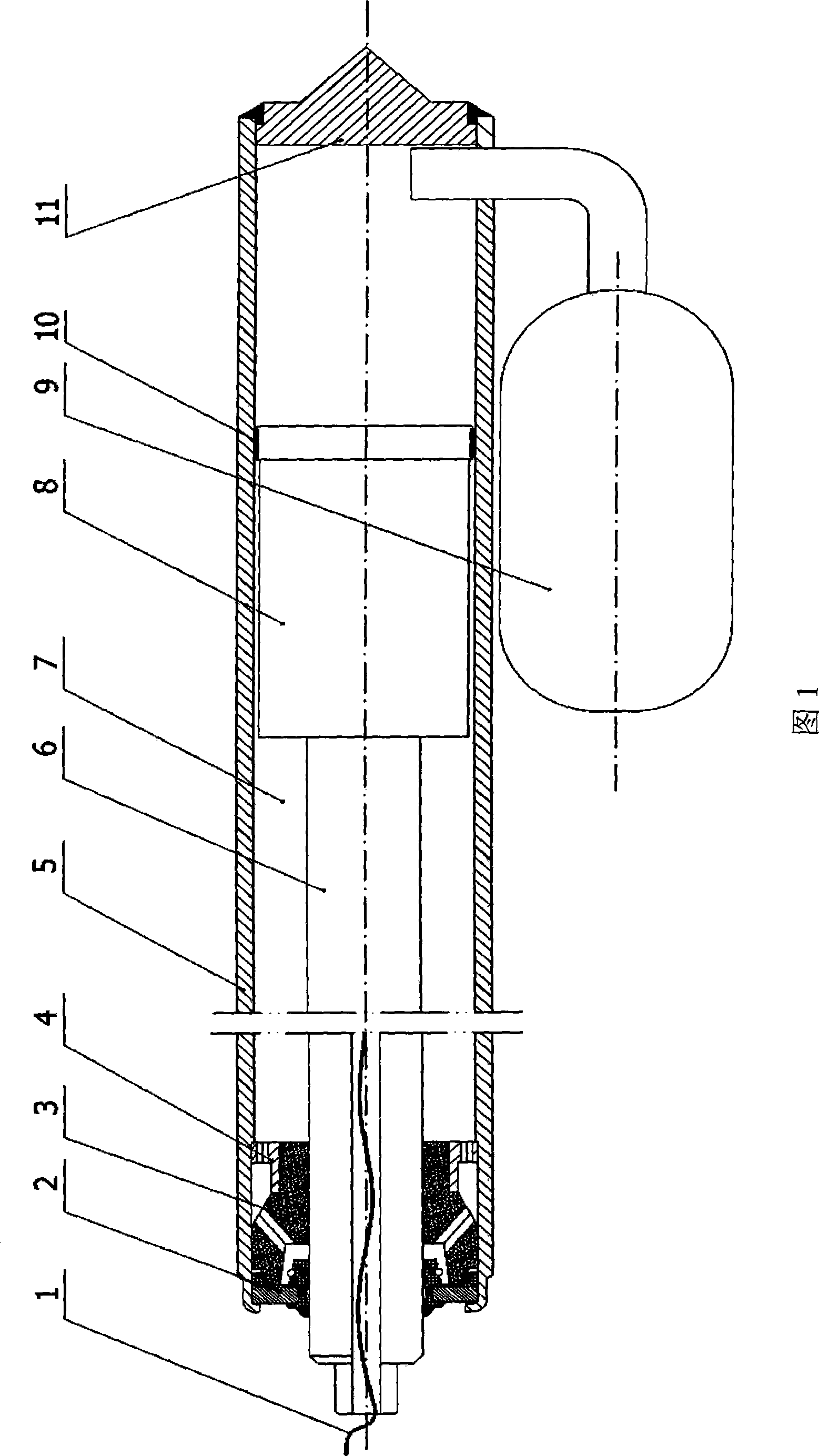

[0018] The overall structure of the dual-channel magneto-rheological damper with channel gating capability is shown in Figure 1. It mainly consists of lead wire 1, oil seal 2, guide seat 3, guide seat support 4, working cylinder 5, piston rod 6, magnetorheological fluid 7, piston assembly 8, compensator 9, guide ring 10, and working cylinder base 11. Among them, the oil seal 2, the guide seat 3, and the guide seat support 4 jointly constitute the sealing device of the magneto-rheological damper, and together with the piston assembly 8, they complete the guiding function of the damper to prevent the piston rod and the piston assembly from swinging and cracking during reciprocating motion. Shaking; the compensator 9 is used to accommodate the changing volume of the magneto-rheological fluid formed by the piston rod entering and leaving the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com