Method for connecting return conductors of power supply DC coaxial cables and connection portion between power supply dc coaxial cables

A technology of loop conductors and coaxial cables, which is applied in the direction of cable joints, manufacturing coaxial cables, and equipment for connecting/terminating cables, etc., which can solve the problems of insufficient electromagnetic shielding characteristics, enhanced thermal damage of the main insulation layer, and welding operation time Shorten the connection work time, improve the connection usability, and reduce the heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

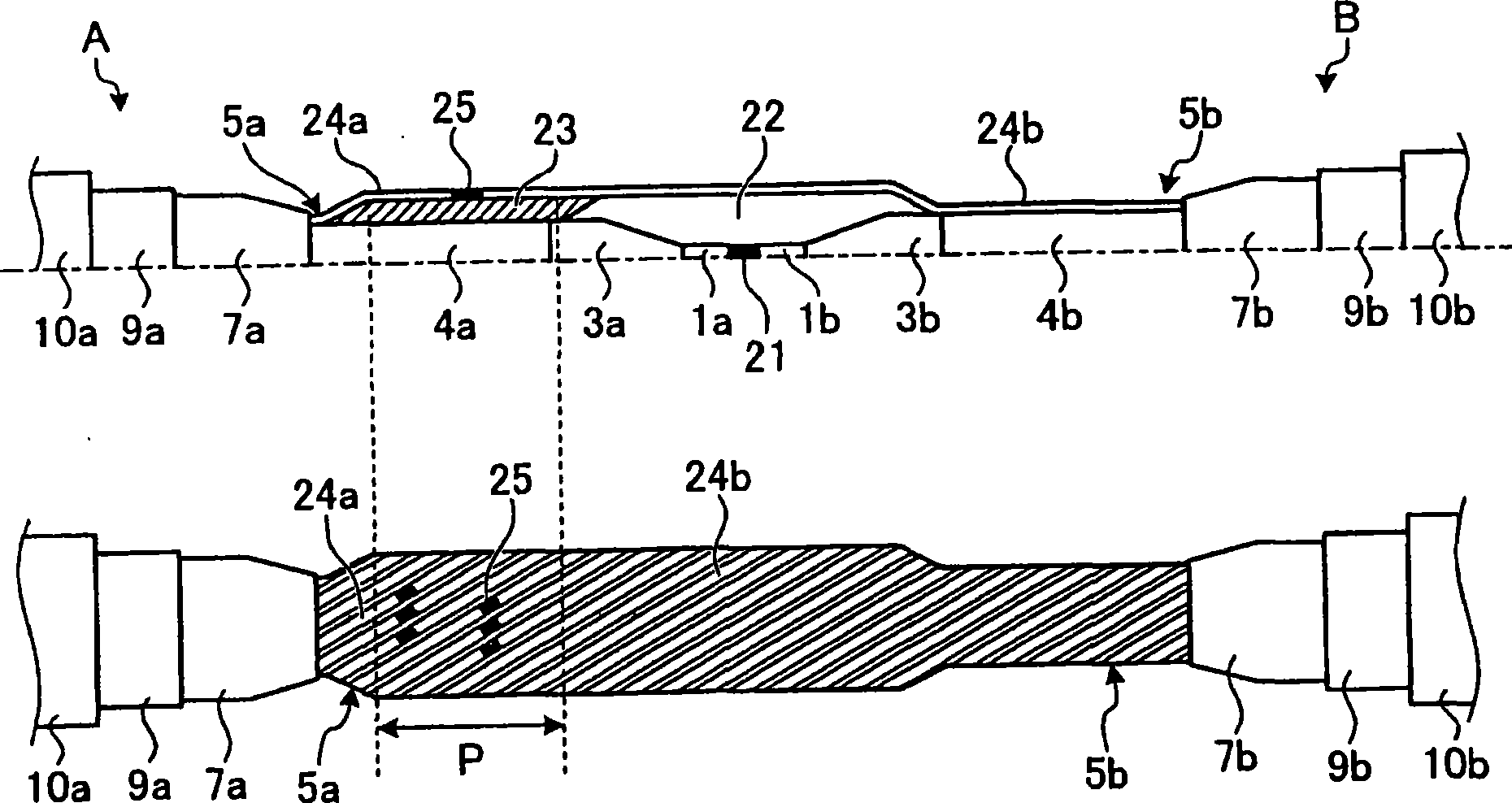

[0065] figure 1 It is a longitudinal sectional view and a partial sectional view of main parts of a DC coaxial cable connection portion for electric power using the loop conductor connection method according to Embodiment 1 of the present invention. The DC coaxial cables A and B to be connected respectively have Figure 17 With the same structure as shown, the anticorrosion layer 10a, 10b, lead cladding 9a, 9b, loop insulator 7a, 7b, outer semiconducting layer 4a, 4b, main insulating layer 3a, 3b are peeled off layer by layer, so that the leading end is exposed. Body 1a, 1b, so that the main conductor 1a, 1b is welded. Reference numeral 21 is a welded portion of the main conductors 1a, 1b. The main conductors 1a, 1b and their solder connections 21 are insulated by a reinforced main insulation layer 22 formed across the main insulation layers 3a, 3b of the two cables. In addition, a buffer layer 23 is provided on the outer semiconductive layer 4a of a square DC coaxial cable...

Embodiment approach 2

[0069] Although the above-mentioned first embodiment is the case where the number and wire diameter of the return conductor core wires of the DC coaxial cable to be connected are the same, but for the case where the number and wire diameter of the return conductor core wires are different, the present invention also Connection of loop conductors is possible. image 3It is an explanatory diagram of a connection method when the number and wire diameter of the loop conductor core wires according to Embodiment 2 of the present invention are different. In Embodiment 2, in Embodiment 1, the DC coaxial cable A is replaced with a DC coaxial cable C having a different number and diameter of loop conductor core wires. In addition, since the other configurations are the same as in Embodiment 1, the same parts are given the same reference numerals. In Embodiment 2, the number of core wires constituting each return conductor core wire bundle 24b, 24c is adjusted so that the number of retu...

Embodiment approach 3

[0071] Figure 5 It is an explanatory drawing explaining the loop conductor connection method of Embodiment 3 of this invention. In this connection method, although the loop conductor core wires 12b, 12c of both DC coaxial cables B, C are arranged adjacent to each other to form the loop conductor core wire bundles 24b, 24c, it is different from the above-mentioned Embodiment 2 is the same, but each return conductor core wire bundle 24b, 24c is connected by welding the front ends of both return conductor core wire bundles 24b, 24c to separately prepared relay wire bundles 26, respectively.

[0072] In the method for connecting the loop conductors described above, compared with the case of directly welding the loop conductor core strands of the DC coaxial cables B and C, it is easier to adjust the welding position of the front end of the loop conductor core strands. In addition, when the configuration (wire diameter and number of wires) of the loop conductor core wire harness t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com