Composite roll mixed with reinforcement cast iron base and manufacture method thereof

A composite roll and cast iron technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of consuming resources, affecting the wear resistance of rolls, and preventing inclusions from being discharged, so as to save resources, improve wear resistance and high temperature hard red effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] To prepare a hybrid reinforced iron-based composite roll with a size of Φ219mm×1000mm and a wall thickness of 35mm, the thickness of the composite layer (working layer) is required to be 2mm to 3mm.

[0035] The preparation process steps of the present embodiment are as follows:

[0036] A: Tungsten wire with a diameter of 0.25mm is used as the raw material of the reinforcing phase, and the tungsten wire is woven into a mesh. The mesh size of the tungsten wire mesh is 0.5mm in the warp direction and 8mm in the weft direction; 1000mm, the width is 3.14×219×1=686.7mm, take the value of 700mm.

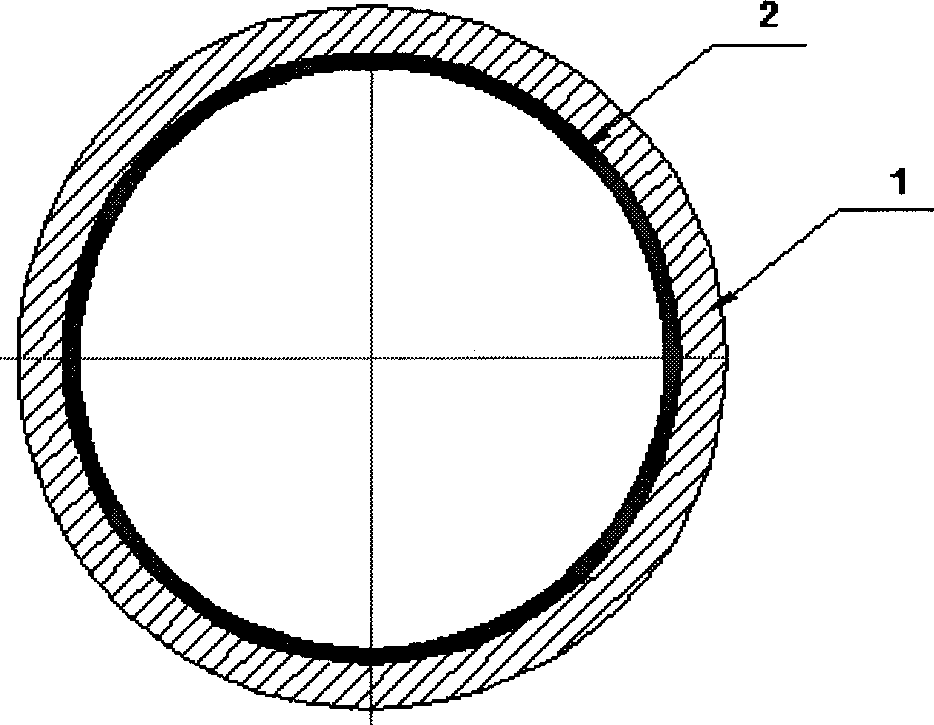

[0037] B: Put the tungsten wire mesh close to the inner wall of the mold, and the tungsten wire mesh basically forms a circle on the inner wall of the mold (such as figure 1 shown).

[0038] C: When the speed of the centrifuge is 500rpm, pour high-strength gray cast iron with a temperature of 1300°C to 1350°C into the mold of the centrifuge, and pull it out after solidifying for ...

Embodiment 2

[0041] This embodiment is to prepare a hybrid reinforced iron-based composite roll with a size of Φ315mm×1000mm and a wall thickness of 45mm. The thickness of the composite layer (working layer) is required to be 4mm-5mm.

[0042] The preparation process steps of the present embodiment are as follows:

[0043] A: Tungsten wire with a diameter of 0.25mm is used as the raw material of the reinforcing phase, and the tungsten wire is woven into a mesh. The mesh size of the tungsten wire mesh is 0.5mm in the warp direction and 8mm in the weft direction. The tungsten wire mesh is intercepted and its length is 1000mm, the width is 3.14×315×2=1978.2mm, take the value of 2000mm.

[0044] B: Put the tungsten mesh close to the inner wall of the mold, and the tungsten mesh basically forms two circles on the inner wall of the mold (such as figure 1 shown).

[0045] C: When the speed of the centrifuge is 550rpm, pour high-strength gray cast iron with a temperature of 1300°C to 1350°C into...

Embodiment 3

[0048] This embodiment is to prepare a hybrid reinforced iron-based composite roll with a size of Φ315mm×1800mm and a wall thickness of 45mm, and the thickness of the composite layer (working layer) is required to be 6mm-8mm.

[0049] The preparation process steps of the present embodiment are as follows:

[0050] A: Tungsten wire with a diameter of 0.25mm is used as the raw material of the reinforcing phase, and the tungsten wire is woven into a mesh. The mesh size of the tungsten wire mesh is 0.5mm in the warp direction and 8mm in the weft direction. The tungsten wire mesh is intercepted and its length is 1800mm, the width is 3.14×315×4=3956.4mm, take the value of 4000mm.

[0051] B: Put the wire mesh close to the inner wall of the mold, and the tungsten wire mesh basically forms four circles on the inner wall of the mold (such as figure 1 shown).

[0052] C: When the rotating speed of the centrifuge is 600rpm, pour high-strength gray cast iron with a temperature of 1300°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com