Cold roller steel strip blowing and drawing type dust catching device

A technology for cold-rolled strip steel and dust is applied in the field of dust source control devices, which can solve the problems of unsatisfactory dust control effect of pickling unit and levelling unit, increase power consumption, affect production process, etc., and achieve good dust source control effect. , the effect of saving power and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

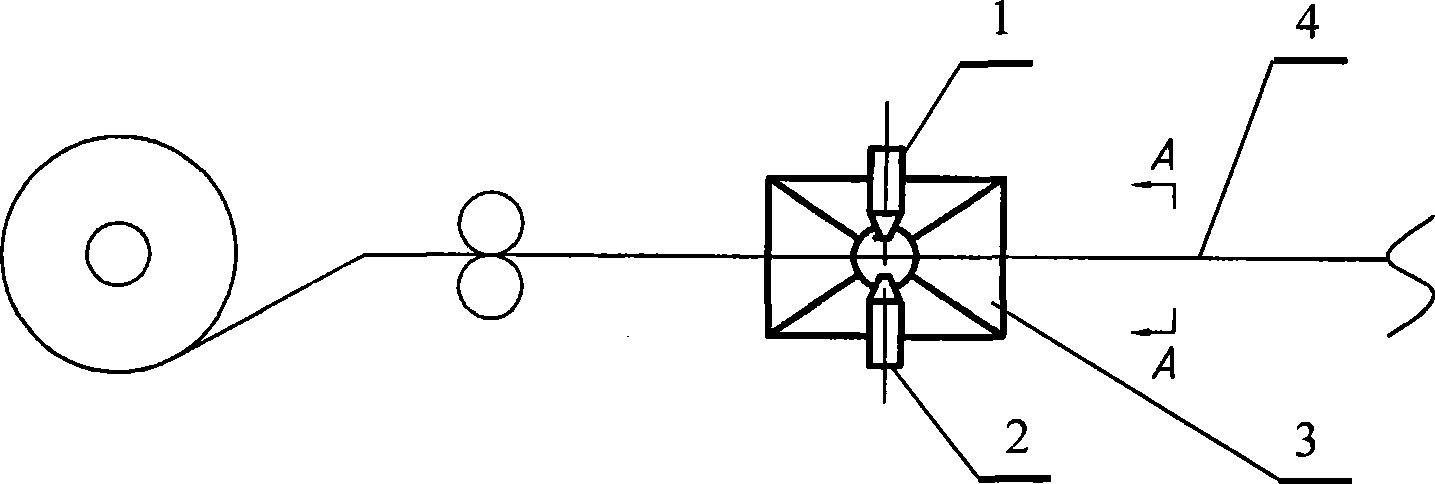

[0018] The utility model relates to a blowing-suction dust collection device for cold-rolled strip steel. The device as figure 1 Shown: It consists of 1 upper nozzle 1, 1 lower nozzle 2 and 1 suction hood 3. The upper nozzle 1 and the lower nozzle 2 are arranged above and below the same side of the steel strip 4 respectively, the installation angle of the upper nozzle 1 and the lower nozzle 2 can be adjusted, and the upper nozzle 1 and the lower nozzle 2 are connected to the compressed gas source through a pipeline; The suction hood 3 is arranged on the other side of the steel strip 4, the suction hood 3 is opposite to the upper nozzle 1 and the lower nozzle 2, and the suction hood 3 is connected with the dust removal pipeline.

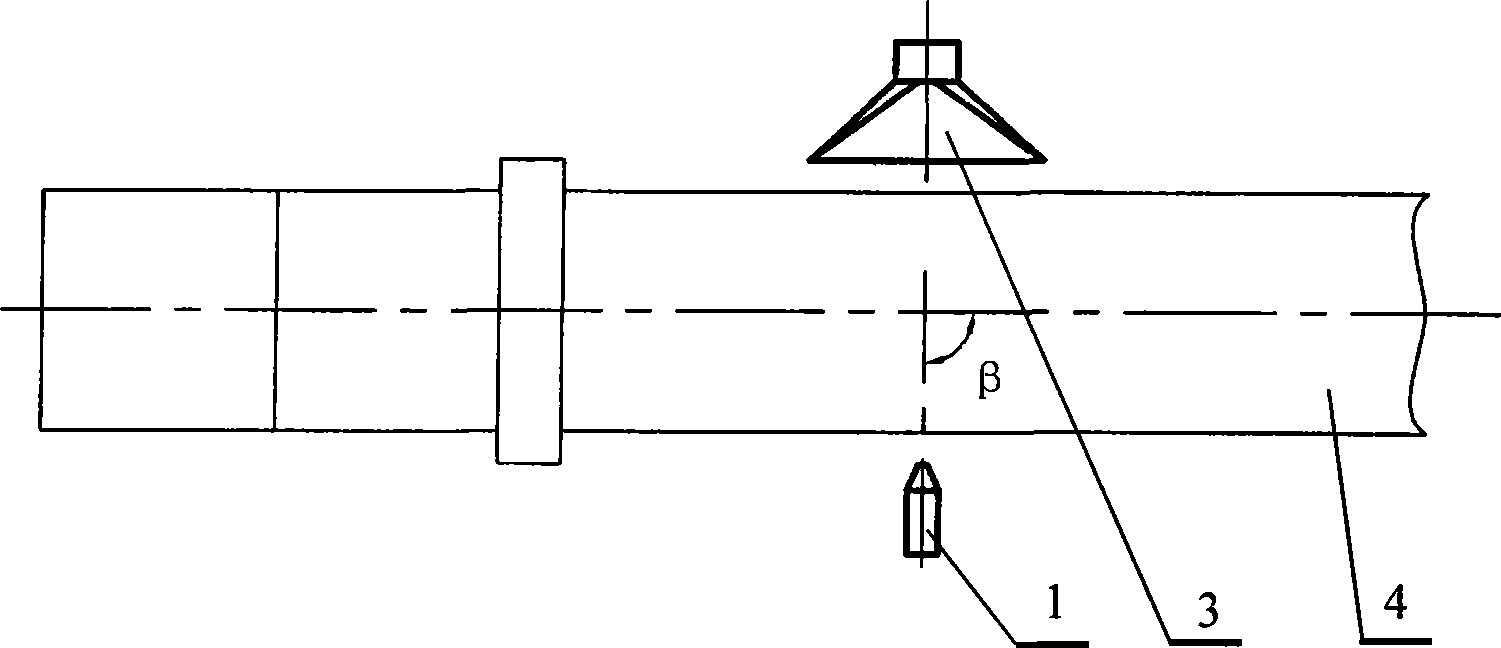

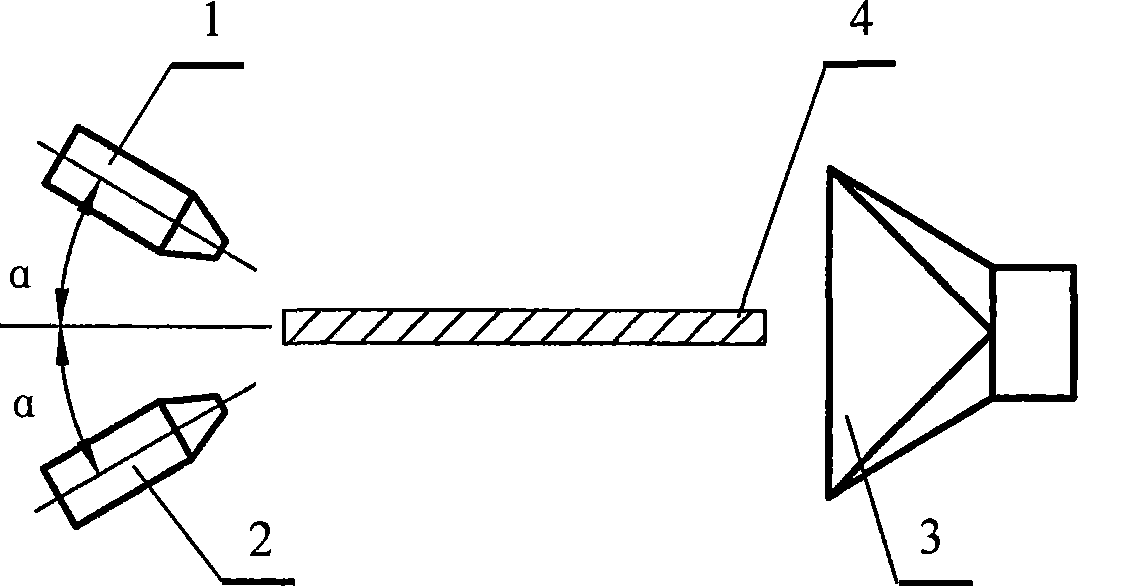

[0019] In this embodiment 1, the gauge pressure of the compressed gas source is 1.5-2Mpa; the installation angle of the upper nozzle 1 and the lower nozzle 2 is: the angle between the vertical plane is as follows: image 3 The shown α is 0~10°, the ...

Embodiment 2

[0021] The utility model relates to a blowing-suction dust collection device for cold-rolled strip steel. The gauge pressure of the compressed gas source is 0.05 ~ 1Mpa; the installation angle of the upper nozzle 1 and the lower nozzle 2 is: the angle between the vertical plane is as follows: image 3 The α shown is 10~15°, and the angle between the horizontal plane is as figure 2 The indicated β is 15 to 70°.

[0022] All the other are with embodiment 1.

Embodiment 3

[0024] The utility model relates to a blowing-suction dust collection device for cold-rolled strip steel. The device is similar to figure 1 As shown, it consists of 2 upper nozzles 1, 2 lower nozzles 2 and 1 suction hood 3. 2 upper nozzles 1 and 2 lower nozzles 2 are respectively arranged above and below the same side of the strip steel 4, the installation angle of the upper nozzle 1 and the lower nozzle 2 can be adjusted, and the 2 upper nozzles 1 and 2 lower nozzles 2 pass through The pipeline is connected with the compressed gas source; the suction hood 3 is arranged on the other side of the steel strip 4, the suction hood 3 is opposite to the upper nozzle 1 and the lower nozzle 2, and the suction hood 3 is connected to the dust removal pipeline.

[0025] In this embodiment 3, the gauge pressure of the compressed gas source is 1-1.5Mpa; the vertical plane installation angles of the two upper nozzles 1 and the two lower nozzles 2 are 0-10° and 10-20° respectively , The ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com