Use of laser honing technique in ocean engine cylinder liner

An engine cylinder and engine technology, applied in honing machine tools, laser welding equipment, manufacturing tools, etc., can solve problems such as inability to adapt to high-end engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

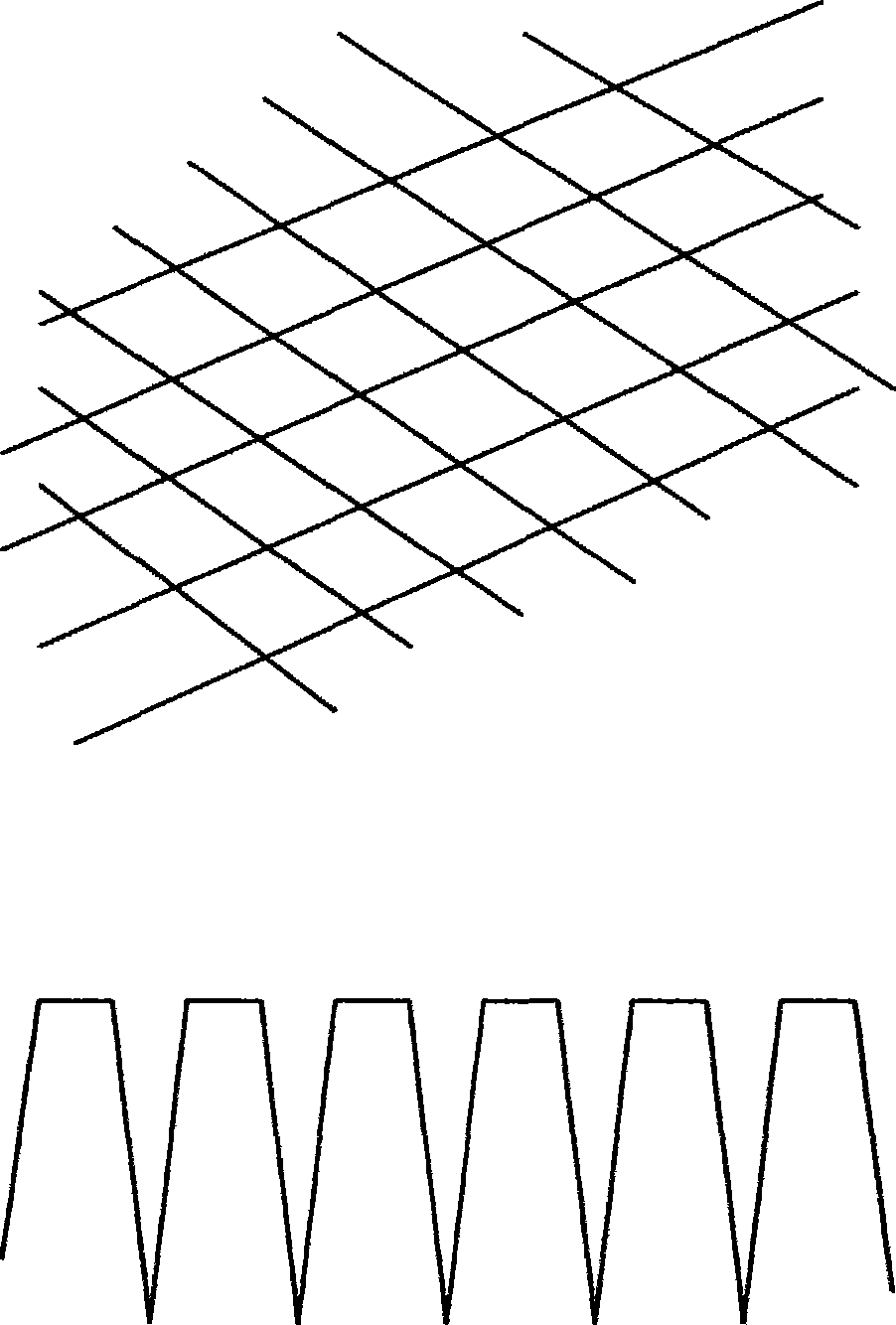

[0005] During rough honing, the macroscopic shape of the inner hole of the cylinder liner is determined, and the consistency of cylindricity and margin must be ensured to provide a basic surface for laser shaping.

[0006] According to the performance requirements of the engine, the type of laser sculpted structure is selected.

[0007] Laser shaping is performed after adjusting the reciprocating and rotating speeds of the laser, light guide system, laser output head and spindle.

[0008] Fine honing is mainly to remove the burrs after laser forming and improve the surface roughness of the inner wall of the cylinder liner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com