Comprehensive assessment method for flue-cured tobacco growing district

A technology of comprehensive evaluation and production area, applied in measurement devices, instruments, scientific instruments, etc., it can solve the problems of complex interaction, large proportion, and conflict of individual index scores in score division areas, so as to eliminate noise data and stabilize The effect of evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

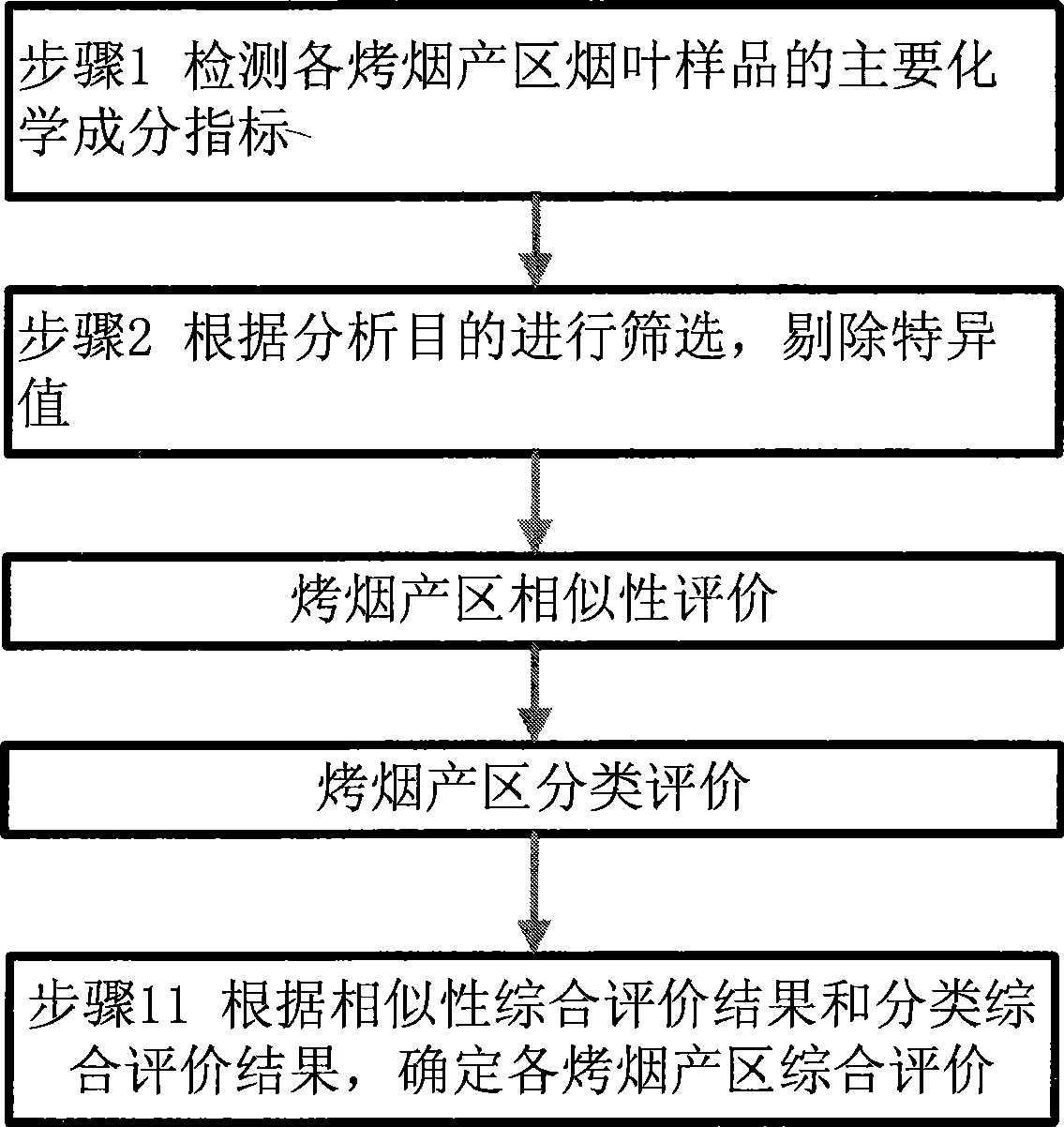

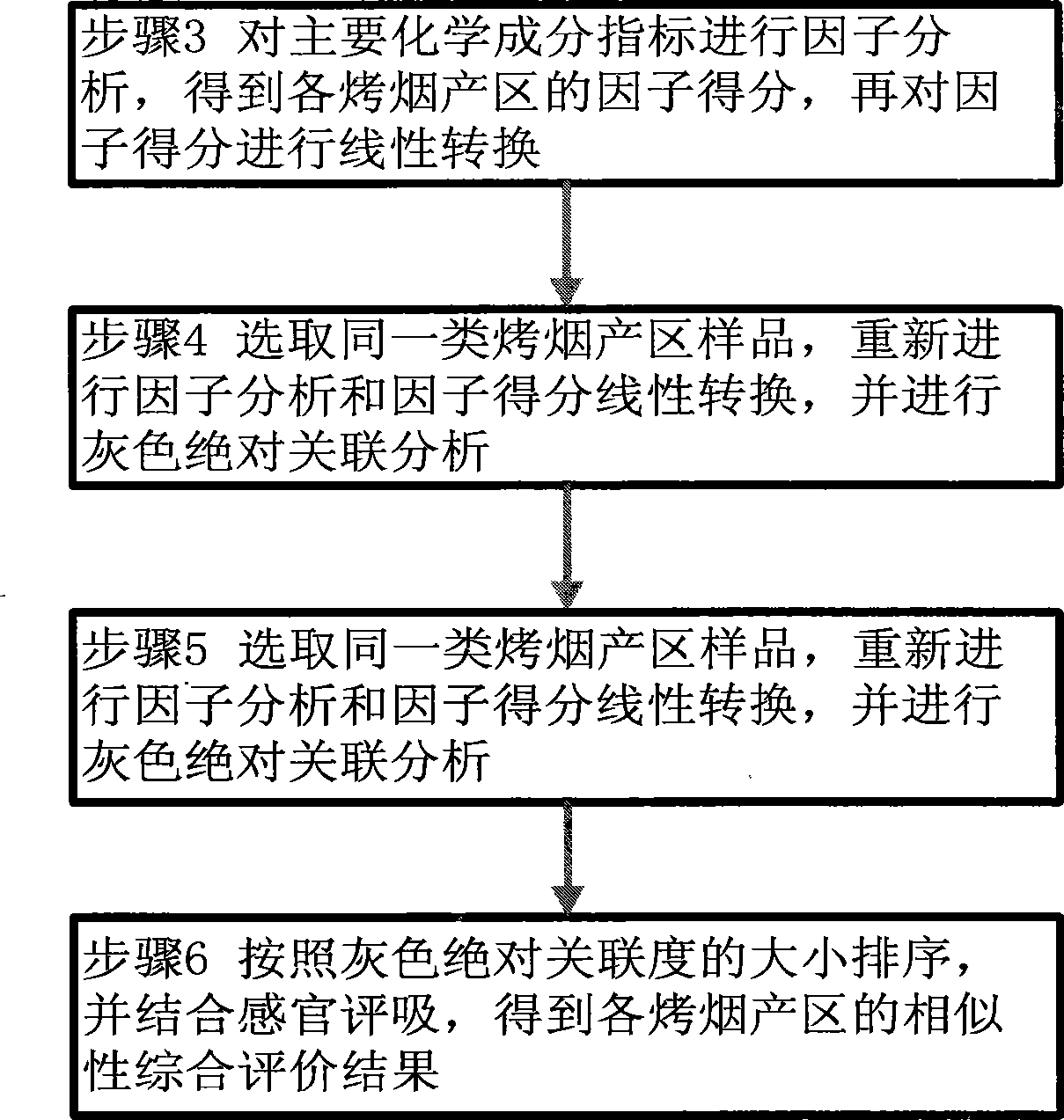

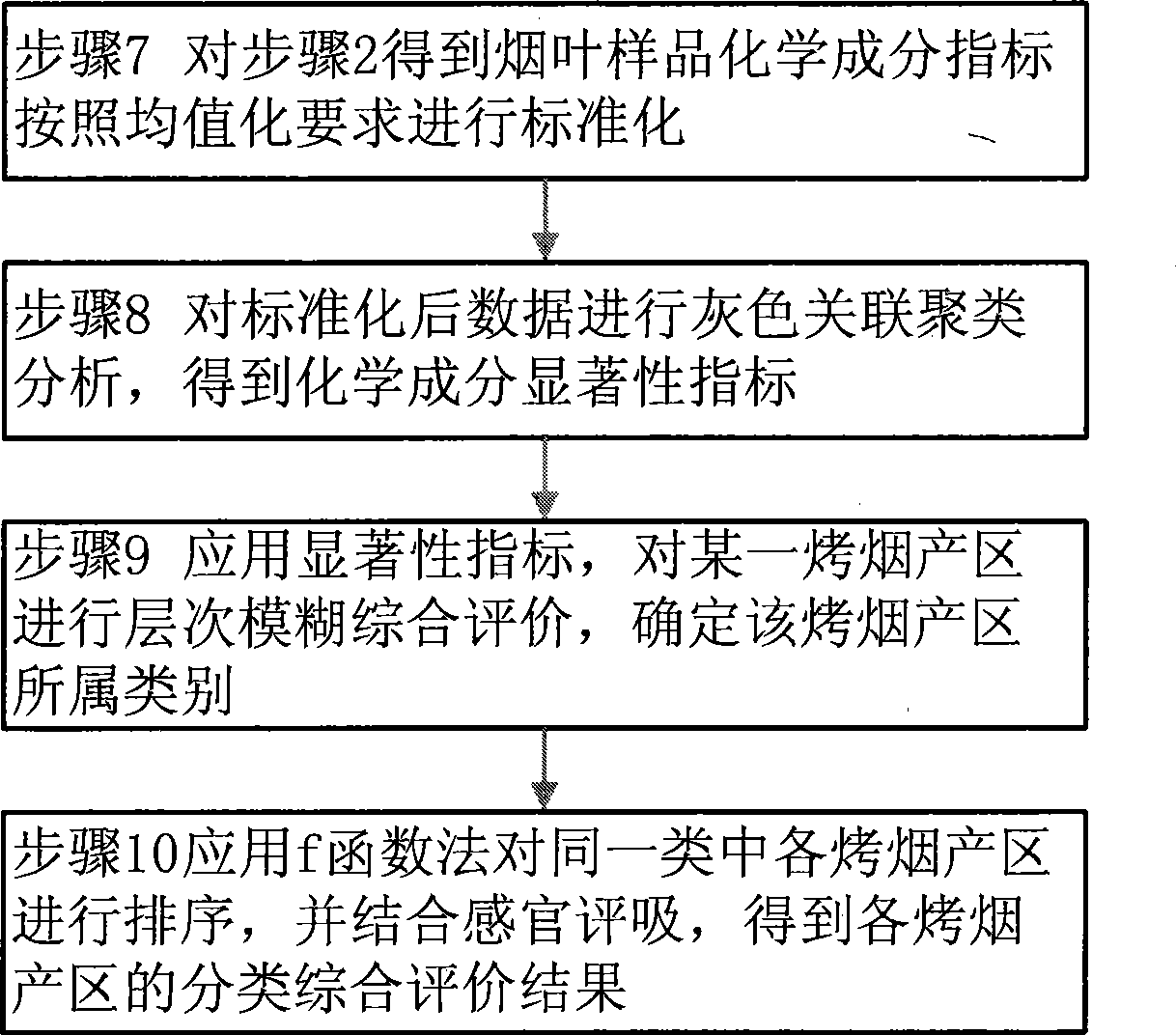

[0055] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0056] Such as figure 1 As shown, start the comprehensive evaluation.

[0057] Step 31 Detect 10 flue-cured tobacco production areas, the numbers are respectively production 01, production 02, production 03, production 04, production 05, production 06, production 07, production 08, production 09, production 10, the main chemical composition indicators of tobacco leaf samples , stored in the database for easy processing. The main chemical composition indicators include: total plant alkaloids, total nitrogen, total sugars, reducing sugars, potassium ions, chloride ions, starch, total volatile acids, total volatile bases, petroleum ether extracts, proteins, cell wall substances, 4-vinyl- 2-methoxyphenol, neophytadiene, oxidized solanone, solanone, polybasic organic acids, carotenoid degradants, aromatic amino acids, Maillard reaction products. Among them, polybasic or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com