Solar cell component

A technology of solar cells and components, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of solar cell reception and waste, and achieve the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

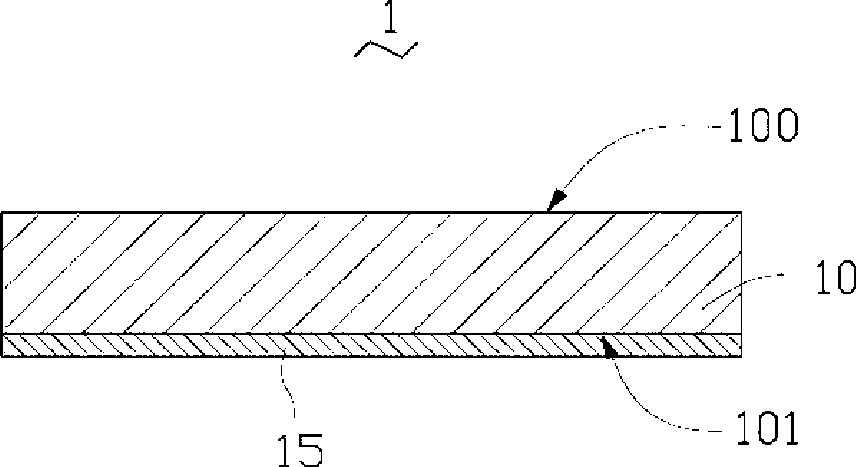

[0014] See figure 1 , the first embodiment of the present invention provides a solar cell assembly 1 , and the solar cell assembly 1 includes a flexible solar cell 10 . The flexible solar cell 10 includes a first surface 100 for receiving solar radiation energy, and a second surface 101 opposite to the first surface 100 . A shape memory alloy layer 15 (Shape Memory Alloys layer, SMA layer) is formed on the second surface 101 .

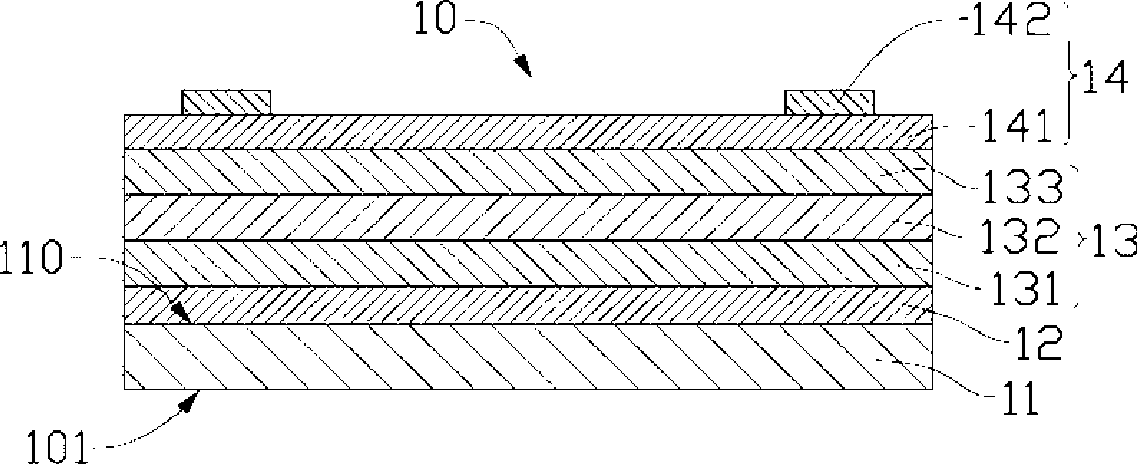

[0015] See figure 2 , the flexible solar cell 10 includes a substrate 11 having a first surface 110 and a second surface 101 . A first electrode layer 12 , a semiconductor structure layer 13 , and a second electrode layer 14 opposite in polarity to the first electrode layer 12 are sequentially formed on the first surface 110 of the substrate 11 .

[0016] In this embodiment, the substrate 11 is a flexible aluminum-magnesium alloy foil (Al-Mg alloy foil), and the thickness of the substrate is approximately between 10 μm and 100 μm. The material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com