Preparation method of buckwheat bread premixing powder

A technology of ready-mixed flour and buckwheat, which is applied in food preparation, baking, baked food, etc., to improve immunity and enhance human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

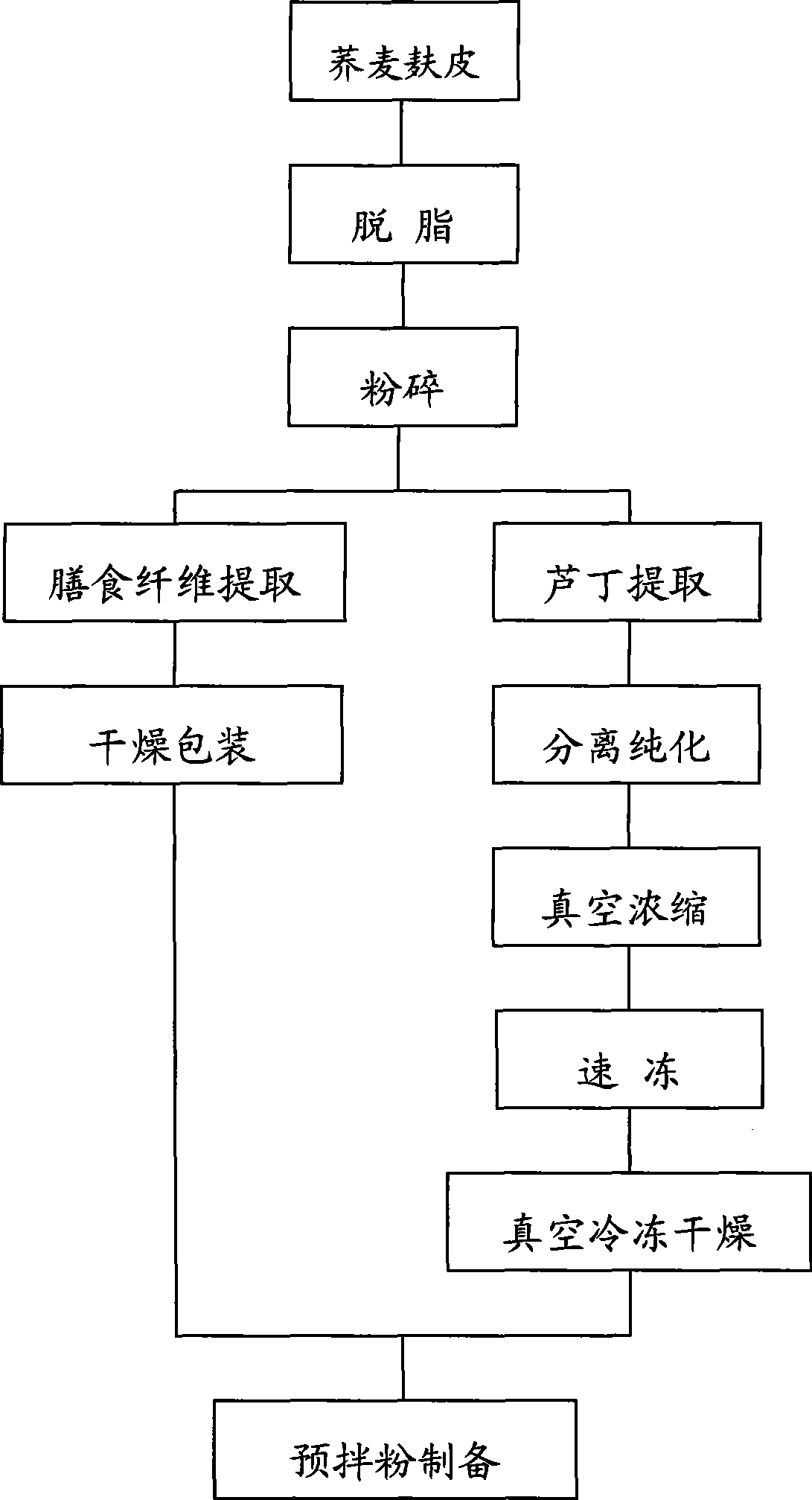

[0030] Further detailed description of the present invention: as figure 1 Shown, a kind of preparation method of buckwheat bread premix powder, take buckwheat bran as raw material, specifically comprise the following steps:

[0031] a. Buckwheat bran defatted

[0032] According to the ratio of buckwheat bran to ethyl acetate (w / w) of 1:8, soak buckwheat bran at 20-25°C for 3-5 hours, dry in a drying oven at 55-75°C for 1-3 hours, and wash with distilled water The remaining ethyl acetate is filtered by suction and then dried in a drying oven at 55-75°C for 1-3 hours to obtain buckwheat defatted bran;

[0033] b. Buckwheat defatted bran crushing

[0034] The above-mentioned buckwheat defatted bran is pulverized to 100-200 mesh by using an ultrafine pulverizer, and is set aside;

[0035] c. Buckwheat bran dietary fiber extraction

[0036] Add water to the above crushed buckwheat defatted bran at a ratio of 10:3~5 (w / w), then add amylase to hydrolyze for 1~3h, the hydrolysis t...

Embodiment 1

[0054] Buckwheat bran defatted

[0055]According to the ratio of buckwheat bran to ethyl acetate (w / w) of 1:8, soak buckwheat bran at 20°C for 3 hours, dry it in a drying oven at 55°C for 1 hour, wash the residual ethyl acetate with distilled water, and extract After filtering, place it in a drying oven at 55° C. for 1 hour to obtain defatted buckwheat bran.

[0056] Buckwheat Defatted Bran Crumble

[0057] The above-mentioned defatted bran is pulverized to 100 mesh with a superfine pulverizer, and is simply packaged for use.

[0058] Buckwheat Bran Dietary Fiber Extraction

[0059] Add water at a ratio of 10:3, hydrolyze with amylase for 1 hour at 45°C, then hydrolyze with glucoamylase for 5 hours at 60°C, finally add trypsin for 3 hours at 30°C, and filter after enzymatic hydrolysis. Precipitate the filtrate with 95% (w / w) ethanol 4 times its volume, let it stand for 3 hours, take the precipitate after suction filtration, that is, buckwheat bran dietary fiber, and set asi...

Embodiment 2

[0076] Embodiment 2 (preferred embodiment)

[0077] Buckwheat bran defatted

[0078] According to the ratio of buckwheat bran to ethyl acetate (w / w) of 1:8, soak buckwheat bran at 25 °C for 4 h, dry it in a drying oven at 65 °C for 2 h, wash the residual ethyl acetate with distilled water, and extract After filtering, place it in a drying oven at 65°C for 23 hours to obtain defatted buckwheat bran.

[0079] Buckwheat Defatted Bran Crumble

[0080] The above-mentioned defatted bran is pulverized to 200 mesh with a superfine pulverizer, and is simply packed for use.

[0081] Buckwheat Bran Dietary Fiber Extraction

[0082] Add water at a ratio of 10:4, hydrolyze with amylase for 2 hours at 65°C, then hydrolyze with glucoamylase for 6 hours at 65°C, finally add trypsin for 3 hours at 35°C, and filter after enzymatic hydrolysis. The filtrate was precipitated with 5 times its volume of 95% (w / w) ethanol, allowed to stand for 4 hours, and after suction filtration, the precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com