Back pressure type blind-hole bricks die

A technology of blind hole bricks and molds, which is applied in the direction of molds, forming indenters, ceramic forming cores, etc., can solve the problems of mandrel design structure, unreasonable processing technology, affecting the strength of bricks, and breaking the mandrel. Vibrating motor and movable plate, reducing mold cost and avoiding the effect of bending and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

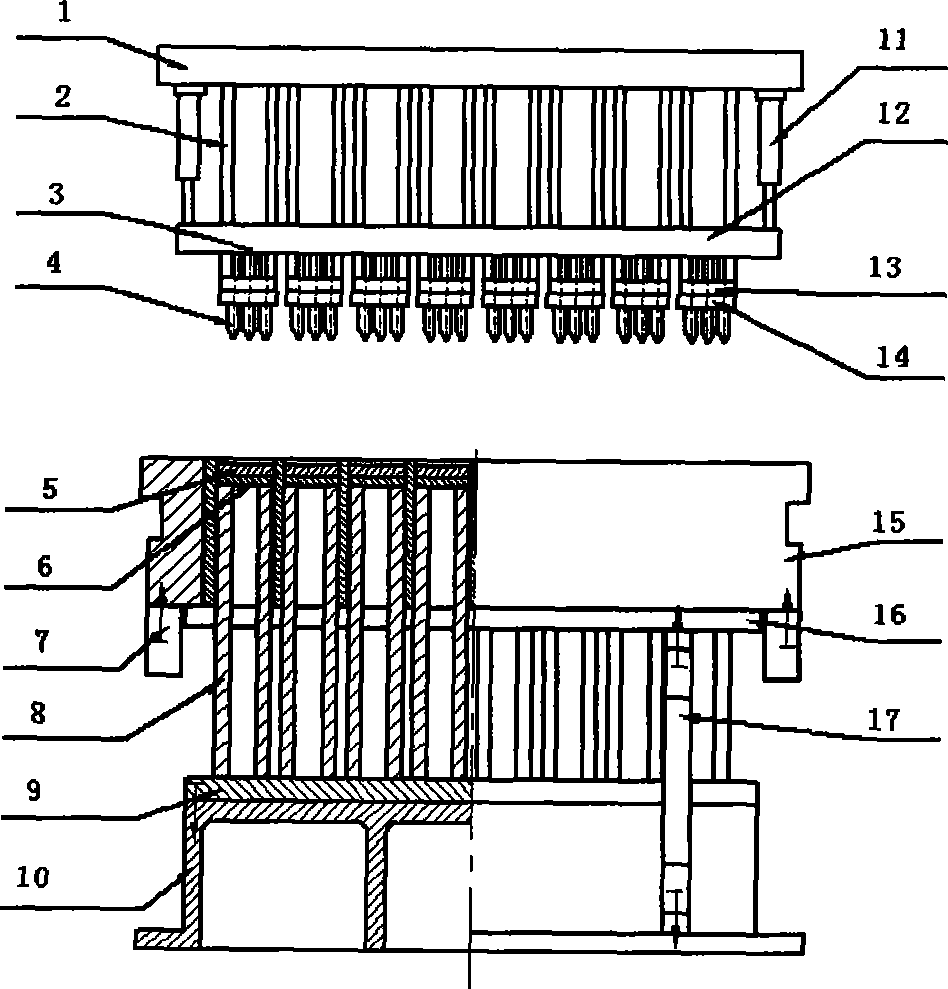

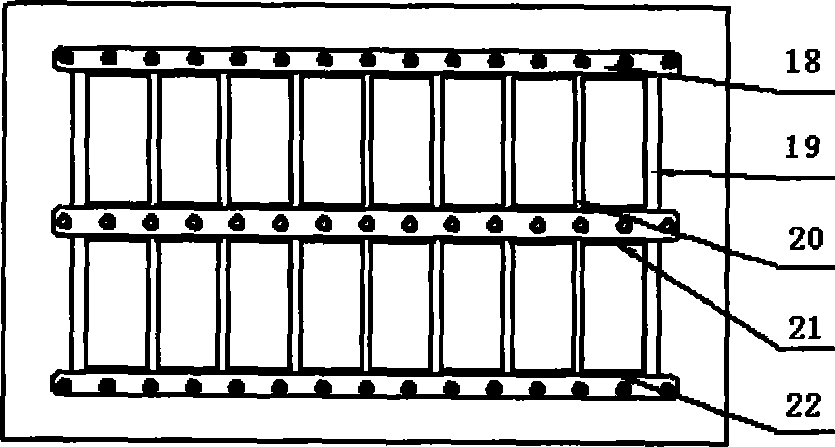

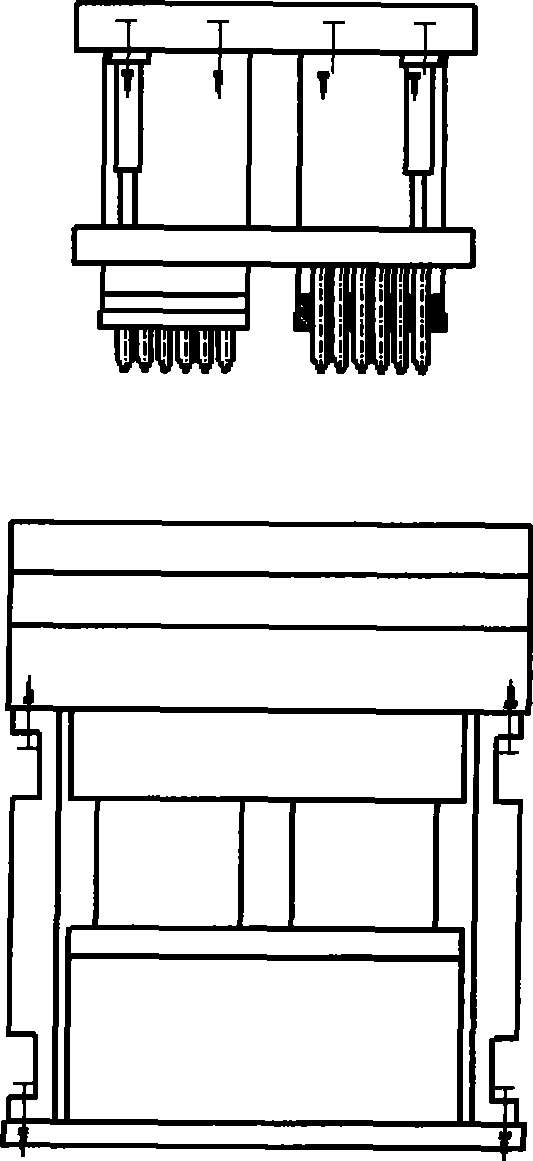

[0022] Such as figure 1 , image 3 As shown, the blind hole brick mold at least includes an upper mold, a lower mold and a middle frame 15, and the upper mold includes an upper template 1, an upper mold base 2, a mandrel backing plate 3, a mandrel 4, an oil cylinder 11, a movable plate 12, and an upper mold The backing plate 13 and the upper mold core 14, the mandrel 4 is connected to the movable plate 12 through the mandrel backing plate 3, and the movable plate 12 is connected to the upper template 1 through the oil cylinder 10. When the mold is working, the oil circuit of the oil cylinder 11 is connected with the press , must be linked with the press, the upper mold core 14 is connected with the upper mold base 2 through the upper mold backing plate 13, and the upper mold base 2 is fixed below the upper template 1; the lower mold includes the lower mold core 5, the lower mold backing plate 13, The push rod 8, the bottom plate 9 and the base 10, the lower mold core 5 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com