Method for preparing micro needle array by means of lithography based on tilting rotary substrate and template

A micro-needle array, tilt-rotation technology, applied in opto-mechanical equipment, manufacturing of micro-structure devices, processes for producing decorative surface effects, etc. Balanced characteristics, good cutting-edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

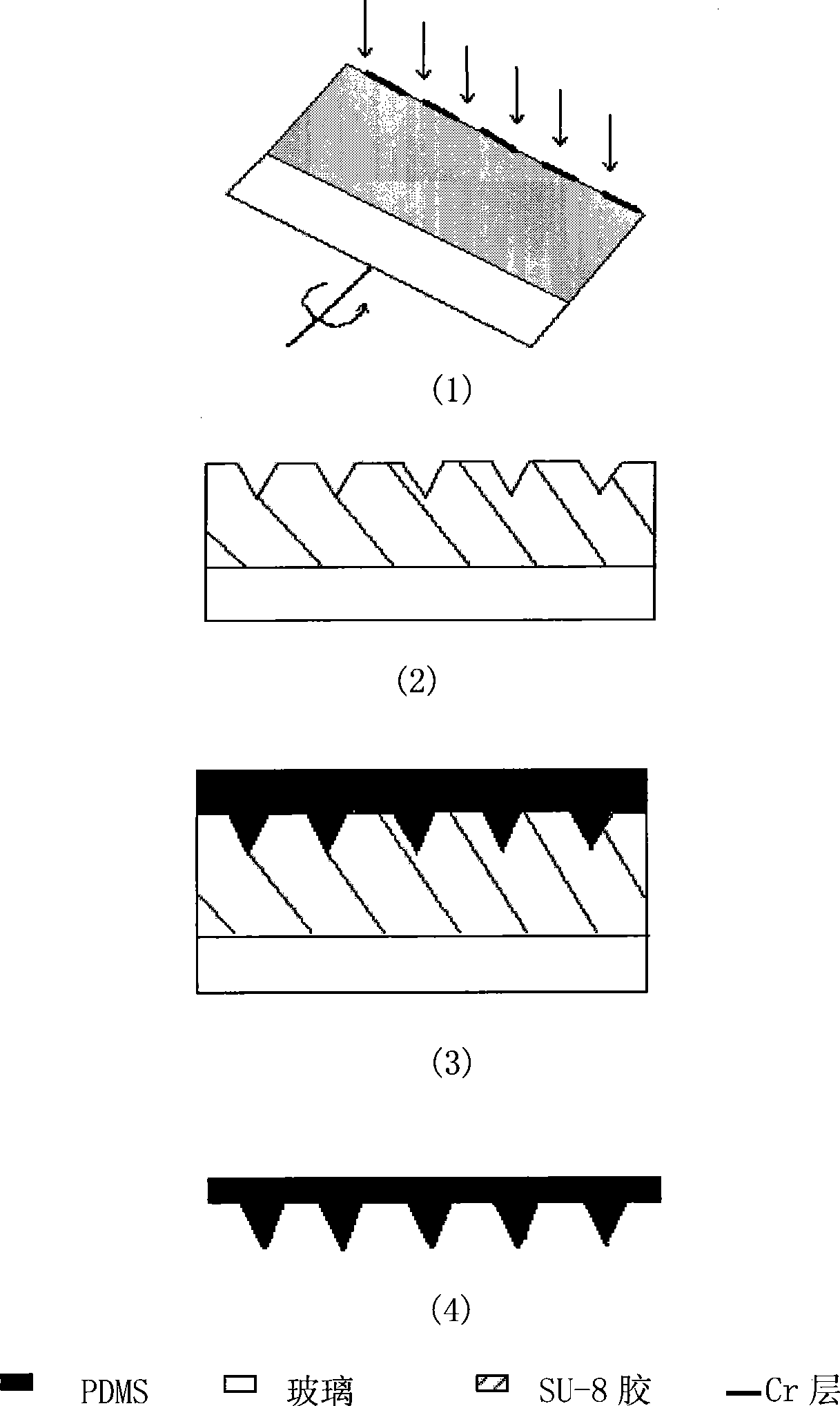

[0026] Embodiment 1: Preparation of metal microneedle array

[0027] 1. Spin-coat 500 μm SU-8 100 on a 500 μm thick cleaned and dried glass substrate, then pre-bake and solidify, and cut flat.

[0028] 2. The mask plate (the pattern is a solid circle, the diameter is 300 μm, the material is Cr, and the thickness is 300nm) is in close contact with the substrate and placed on the substrate fixed on the rotating shaft of the motor. The inclination angle of the substrate is 23°, and Press the speed of 250rad / min as figure 1 rotation shown.

[0029] 3. With a wavelength of 365nm, the light intensity is 3mW / cm 2 Tilt-rotation exposure under UV light for 20 minutes. Development after middle baking (soak in the developing solution of SU-8 glue for 17 minutes, you can get figure 1 The SU-8 conical concave cone structure shown in (2)).

[0030] 4. In figure 1 On the photoresist structure shown in (2), sputter 100 nanometers of Cr, 500 nanometers of Cu, and then use a current densi...

Embodiment 2

[0032] Embodiment 2: Preparation of PDMS microneedle array

[0033] At first carry out step 1-3 in embodiment 1, obtain SU-8 conical concave cone structure, then carry out following operation:

[0034] 1. In figure 1 (2) The photoresist structure is filled with PDMS (the weight ratio of PDMS body and PDMS curing agent is 10:1), and the PDMS is filled in the SU-8 conical concave cone structure mold (SU-8 glue with a diameter of 3 inches The conical-concave structure is filled with about 13 grams of PDMS).

[0035] 2. After filling, the overall structure is as follows: figure 1 As shown in (3), put the above-mentioned whole in a vacuum box to remove air bubbles for more than 1.5 hours.

[0036] 3. After removing the clean air bubbles, heat and cure it in an oven at 80 degrees Celsius for 40 minutes. Cut off the edge of the PDMS and place it in ethanol for 3 minutes. After demoulding, a PDMS microneedle array is obtained.

[0037] The conical microneedle prepared in this ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com