Proximal melting state diffusion technology for preparing SiC fiber/aluminum base composite material

A technology of aluminum-based composite materials and diffusion technology, which is applied in the field of material science, can solve the problems of material performance limitations, low solubility, and difficult control of harmful interface reactions, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

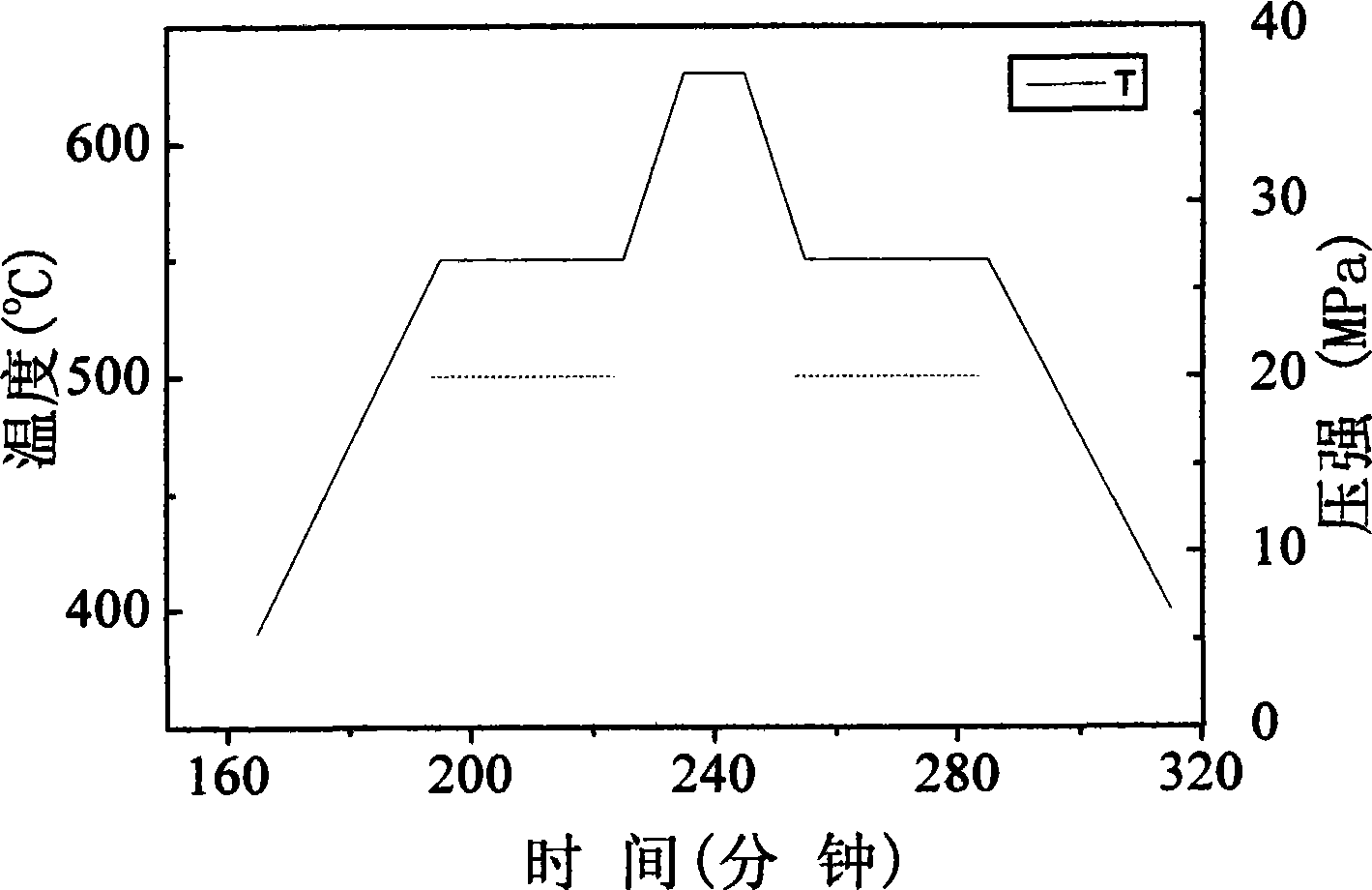

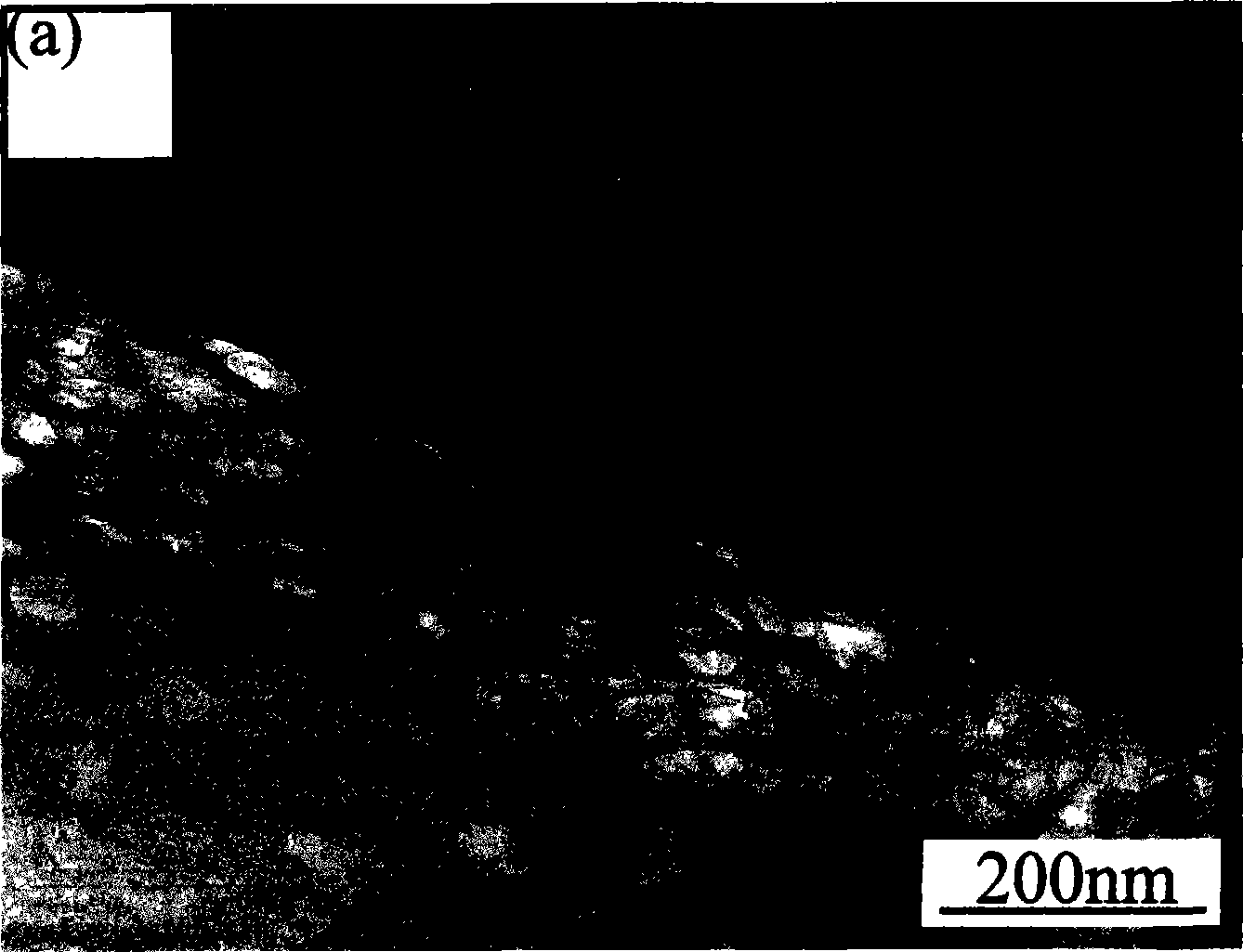

[0019] The substrate used is 5A02 aluminum alloy foil with a thickness of about 100 μm; the reinforcement is W-core SiC fiber with a diameter of 100 μm, and the surface is covered with a carbon-rich layer with a thickness of 1.5 μm. The SiC fiber-reinforced Al-based composite material is prepared by the foil-fiber-foil method. The fibers are wound on a cylindrical drum at a certain distance on a special wire-discharging machine and arranged to form a prefabricated belt, which is fixed with an adhesive and dried. Thin slices of the same size as aluminum foil are alternately put into pure titanium sheaths to make SiC fiber and aluminum alloy prefabricated bodies, and then put into a hot-pressing mold for vacuum hot-pressing using a near-melt diffusion process. The specific process is:

[0020] 1) Pressurize under solid state conditions to fully contact the SiC fiber and the aluminum matrix; pressurize under solid state conditions to fully contact the SiC fiber and the aluminum ma...

Embodiment 2

[0028] The present embodiment and embodiment 1 preparation method and content are basically the same, and its difference mainly lies in:

[0029] The hot pressing parameters are 550°C / 30 minutes / 20MPa, 620°C / 10 minutes / 10MPa, 550°C / 30 minutes / 20MPa.

Embodiment 3

[0031] This embodiment is basically the same as the embodiment 1, the difference mainly lies in: the holding time and pressurization time of the solid-liquid phase interval are shorter, and the pressure is higher. The specific parameters are 600°C / 20 minutes / 30MPa, 630°C / 7 minutes / 0MPa, and 600°C / 20 minutes / 30MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com