Acoustic logging instrument of novel acoustic array structure

A well logging instrument and array structure technology, which is applied in seismology for well logging records, borehole/well components, earthwork drilling and production, etc., can solve the problem of increasing the unsafety of on-site operations, reducing reliability, and increasing the length of instruments To improve the sensitivity and measurement accuracy, simplify the structure of the instrument, and improve the sound field intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

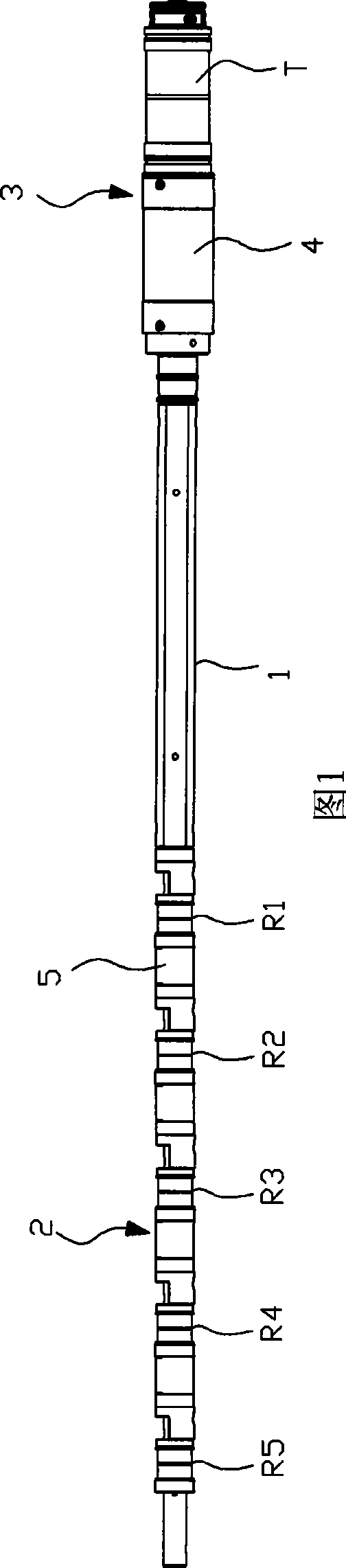

[0022] As shown in Figure 1, the present invention includes: a base 1, the base 1 is made of a circular mandrel made of epoxy resin material, the base 1 includes a receiving area 2 and a transmitting area 3, and the receiving area 2 is arranged at equal intervals in sequence There are five receiving transducers R1, R2, R3, R4, R5, one transmitting transducer T is set in the transmitting area, and a high-voltage pulse excitation part 4 for driving the transmitting transducer T is also set in the transmitting area 3.

[0023] The receiving transducers R1, R2, R3, R4, R5 and the transmitting transducer T are composed of two annular piezoelectric ceramics connected in parallel, and the width of the receiving transducers with R1, R2, R3, R4, R5 is 0-23KHZ. The receiving transducers R1, R2, R3, R4, R5 are arranged at equal intervals with a spacing of 6 inches, and the adjacent receiving transducers R1, R2, R3, R4, R5 are replaced by ring-shaped sound insulation materials. Sound Loop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com