Roll for metal processing, in particular a continuous casting roll, and method of producing such a roll

A technology of metal processing and metal manufacturing, which is applied in the field of continuous casting rolls, can solve the problems of high cost, and achieve the effects of low manufacturing cost, reliable wear resistance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

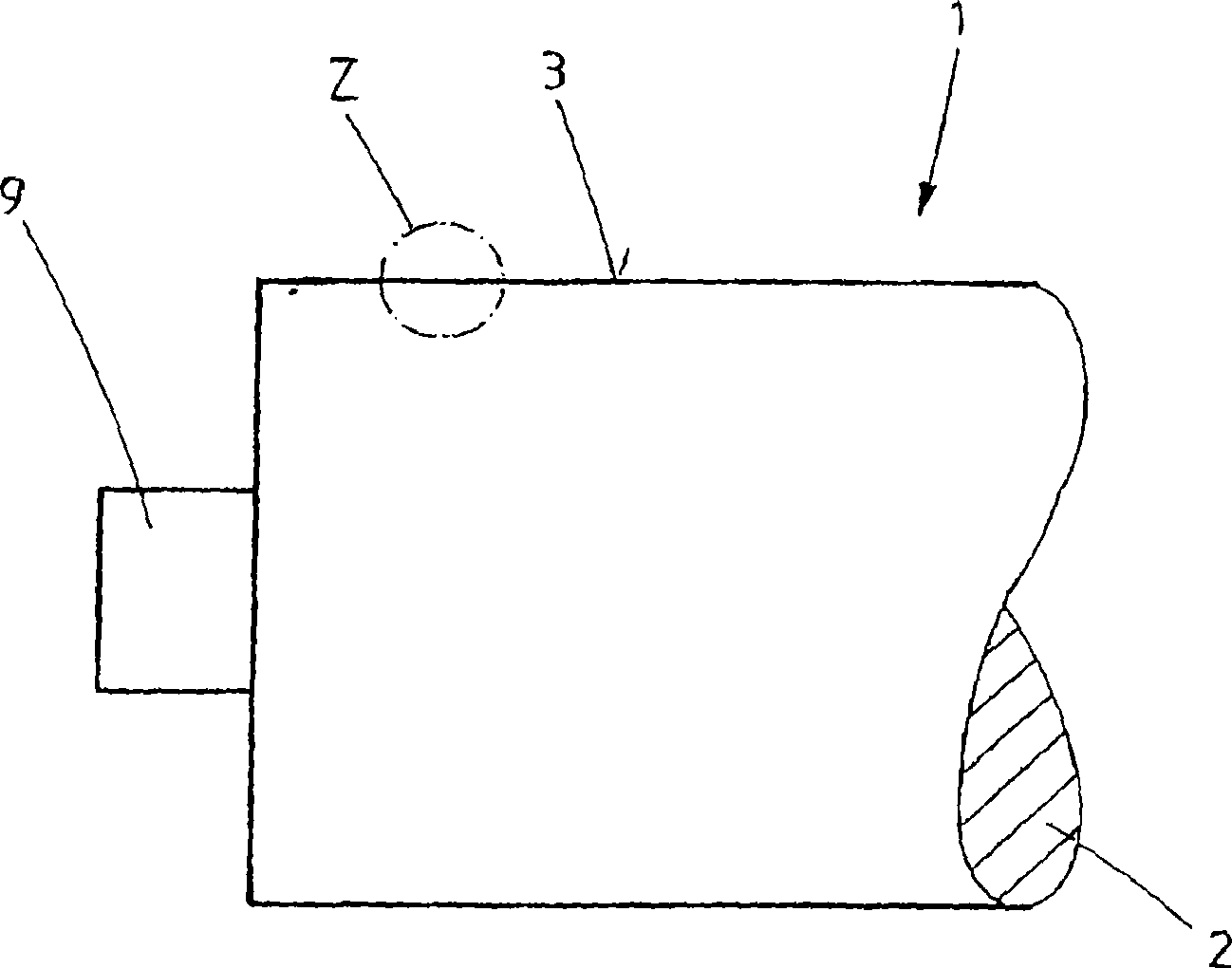

[0033] exist figure 1 A continuous casting roll 1 is seen in the figure, which has a roll neck 9 which is not discussed further here, and which furthermore consists of a cylindrical roll base body 2 in the exemplary embodiment. A coating 3 made of wear-resistant material is plated on the roller base 2, and its structure is in figure 2 described in detail.

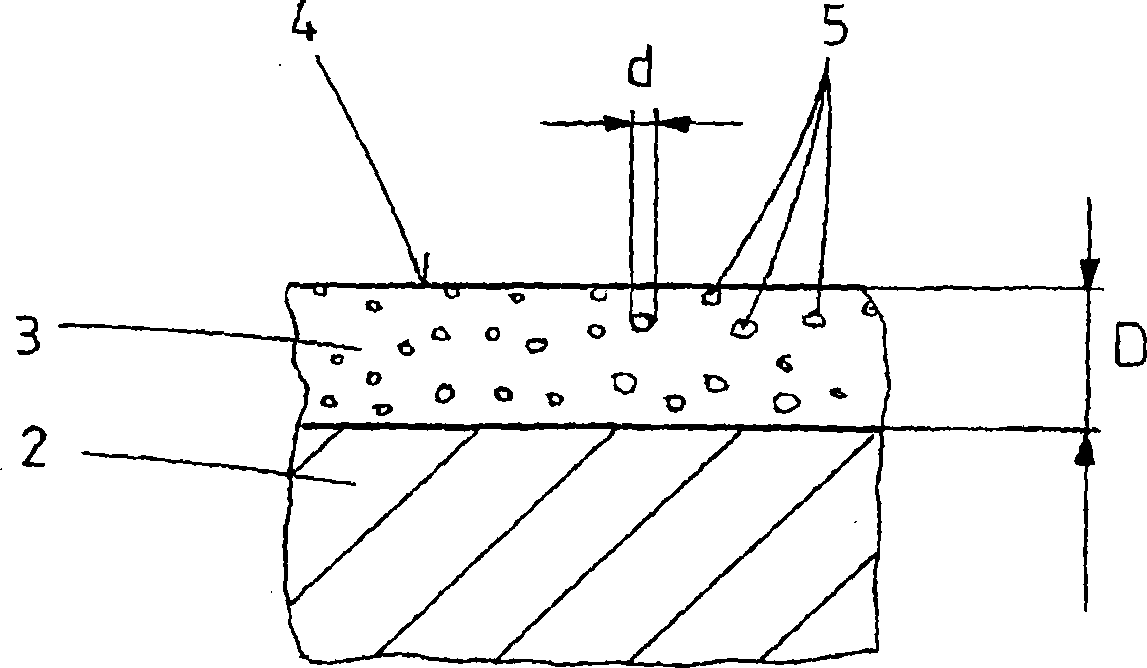

[0034] The coating 3 has a coating thickness D which can be, for example, between 0.05 mm and 2.0 mm. What is important is that the surface 4 of the coating 3 is the running surface of the roll 1 which, in the case of continuous casting rolls, is in contact with the still hot strand and is therefore exposed to high-temperature mechanical and chemical corrosion loads.

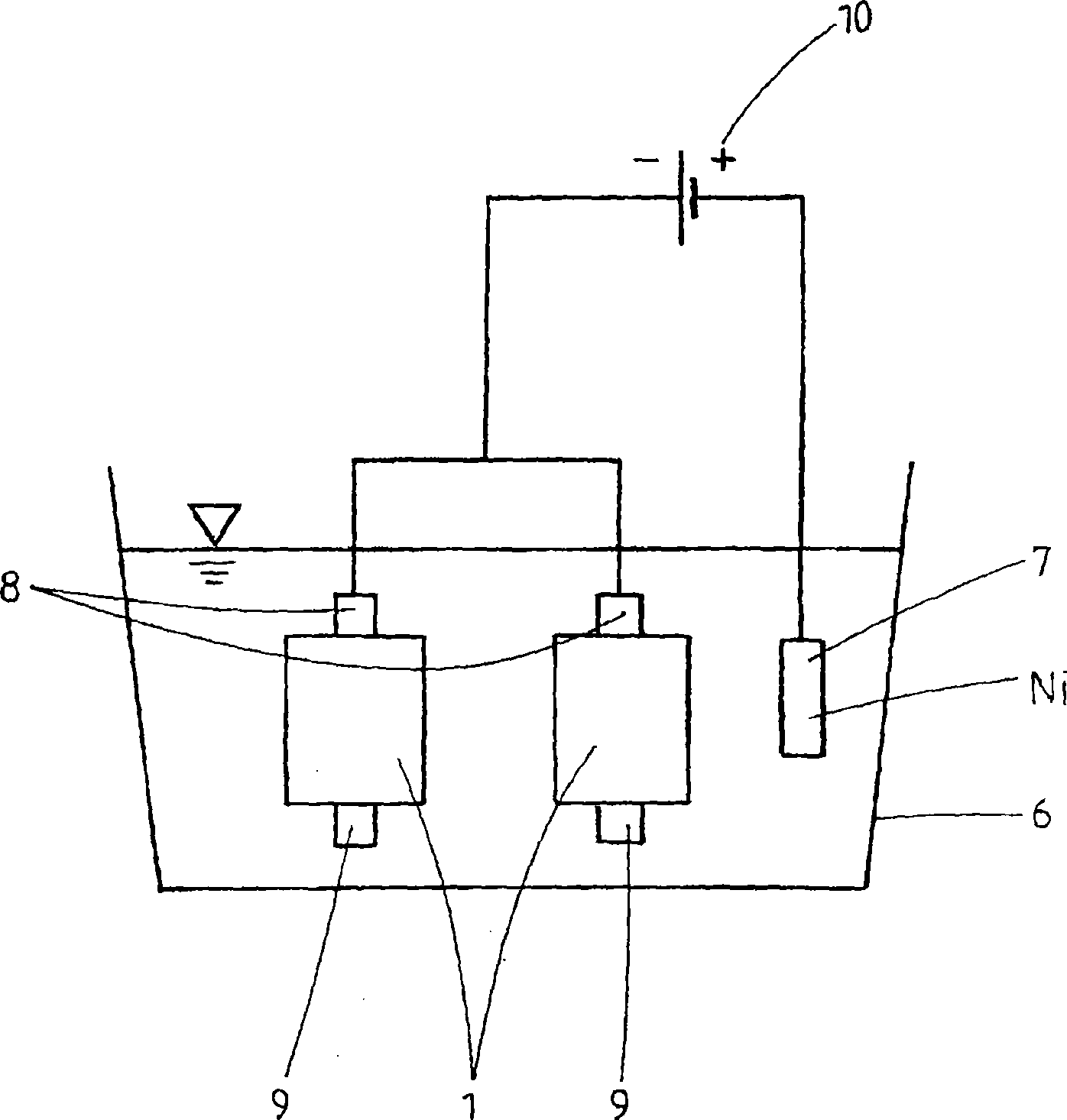

[0035] The coating 3 consists of nickel or a nickel alloy, wherein the coating is applied galvanically (electrolytically) to the roller base 2 (for this see image 3 ).

[0036] In order to increase the in particular mechanical and thermal hardness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com