Method of heat accumulation and heat accumulation system

A heat storage system and heat storage technology, applied in the direction of heat storage equipment, chemical instruments and methods, heat exchanger types, etc., can solve the problems of high heat storage density and reduction of heat storage, so as to improve heat transfer efficiency and increase heat transfer efficiency. The amount of output and the effect of increasing the amount of heat extracted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0084] Hereinafter, a heat storage method according to a first embodiment of the present invention will be described with reference to the drawings.

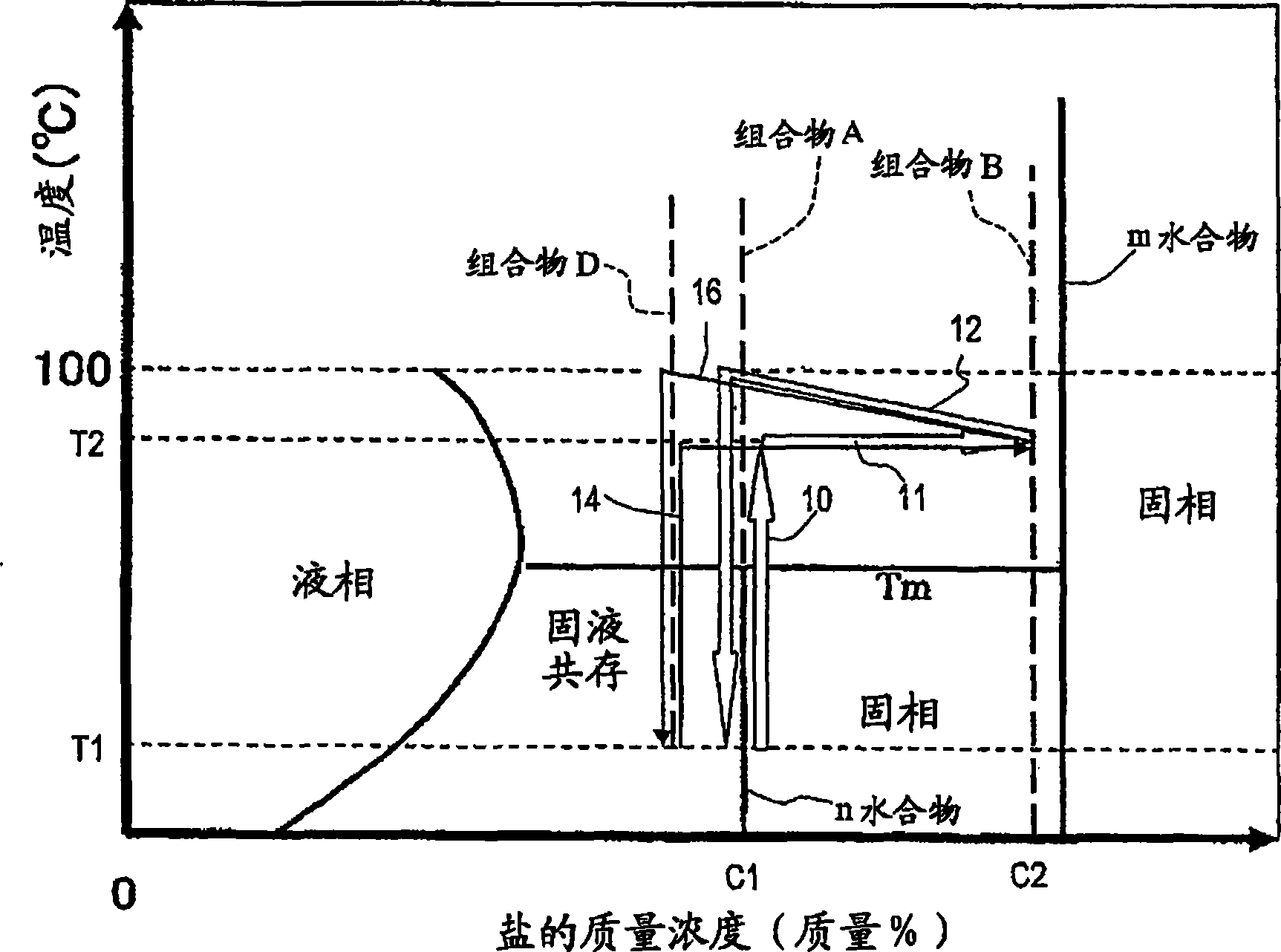

[0085] figure 1 It is a figure for demonstrating an example of the heat storage and heat release process in this embodiment. figure 1 In , the abscissa represents the concentration of the composition, and the ordinate represents the temperature, illustrating a phase diagram showing the state of existence of phases at each composition of inorganic salt and water.

[0086] In this example, as the first composition, a composition A (concentration of inorganic salt: c1) of an n-hydrate in a solid phase at temperature T1 was used. The temperature T1 is defined as room temperature, for example.

[0087] In the heat storage process, as shown by the arrow 10, first if the temperature of the n-hydrate is heated from the temperature T1 to a temperature T2 higher than the phase transition temperature Tm, the dehydration reaction of the n...

no. 2 Embodiment approach

[0104] Hereinafter, a heat storage method according to a second embodiment of the present invention will be described with reference to the drawings.

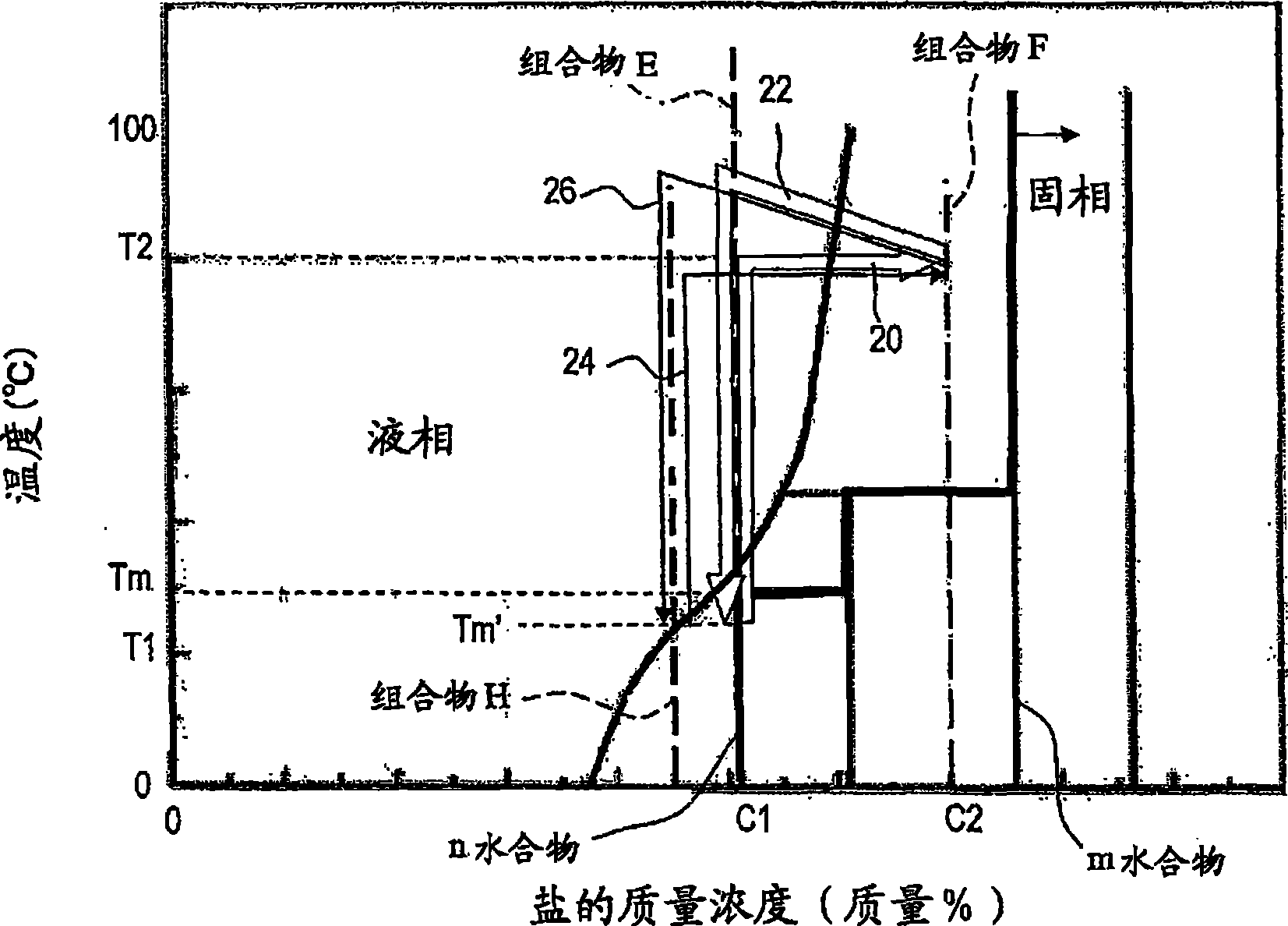

[0105] This embodiment differs from the above-described embodiments in that the first composition becomes the second composition through a liquid-phase monomer state during the heat storage process. That is, in the aforementioned embodiment, when the first composition is heated to the temperature T2, it becomes a solid-liquid coexistence state, and the second composition is obtained by separating water from the first composition in the solid-liquid coexistence state, and In this embodiment, the 1st composition turns into an aqueous solution when heated to temperature T2, and the 2nd composition is obtained by separating water from this aqueous solution.

[0106] figure 2 It is a figure for demonstrating an example of the heat storage and heat release process in this embodiment. figure 2 In the center, the abscissa represent...

Embodiment 1

[0153] The heat storage method of this embodiment will be specifically described below with reference to the drawings.

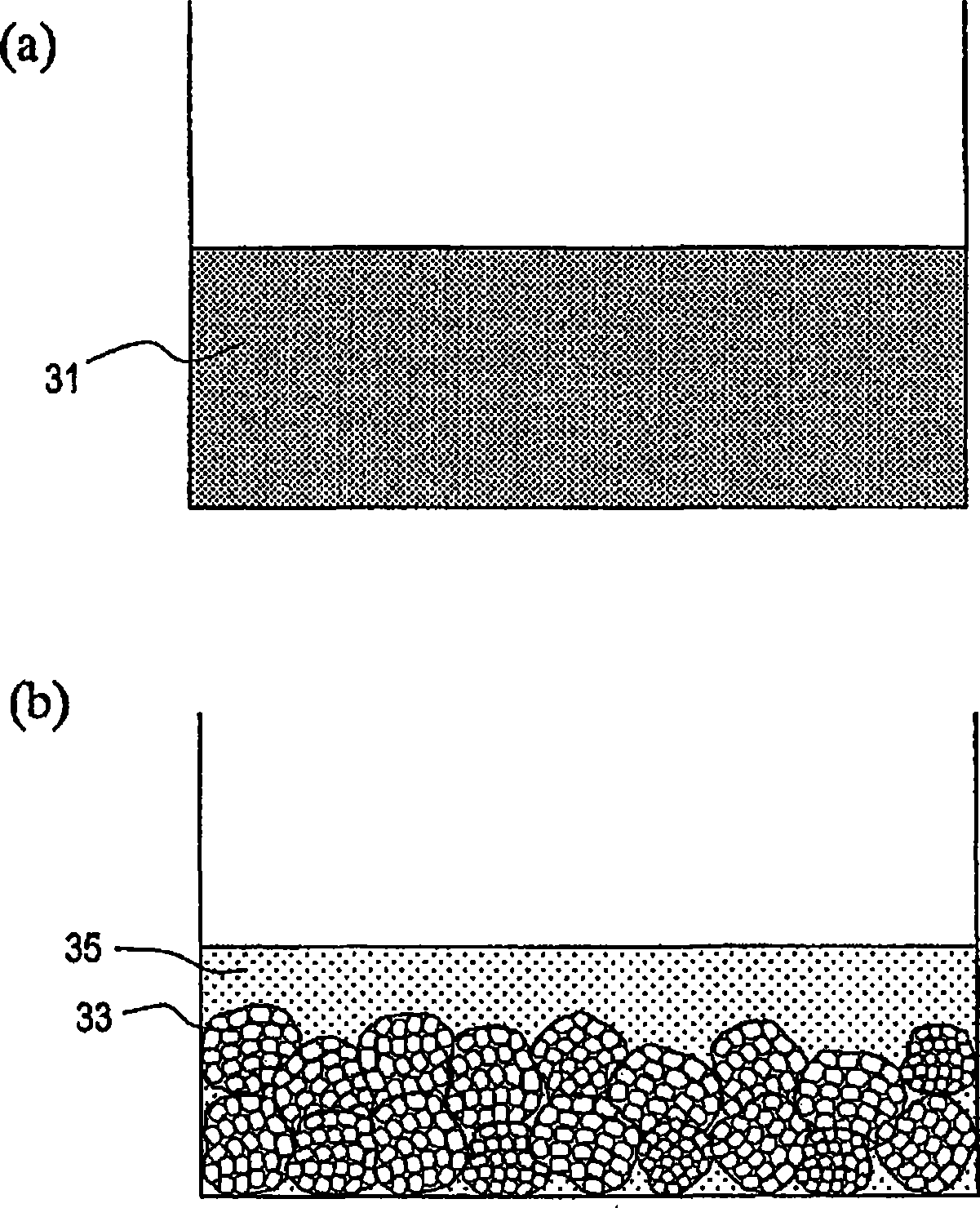

[0154] In this example, a hydrate containing magnesium sulfate and water in a molar ratio of 1:7 was used, and the reference Figure 10 with Figure 11 A heat storage system is described for heat storage and heat release. Figure 12 is the phase diagram of magnesium sulfate and water, and the heat storage process in this embodiment is illustrated by arrow 90 .

[0155] First, magnesium sulfate heptahydrate as the first composition is accommodated in the thermal storage tank 51 . The temperature of magnesium sulfate heptahydrate is room temperature (about 15°C).

[0156] Next, as shown by the arrow 90 , heat storage is performed by obtaining the second composition 92 in a solid-liquid coexistence state at about 80° C. from the magnesium sulfate heptahydrate 91 at room temperature. The second composition 92 is a solid-liquid coexistence state of magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com