Label capable of being labeled using laser without contact, production method and labeling method

A label and laser absorber technology, applied in the field of labels, their production methods and marking on them, can solve the problems of label durability and ease of use, uneven label surface thickness, and increased difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

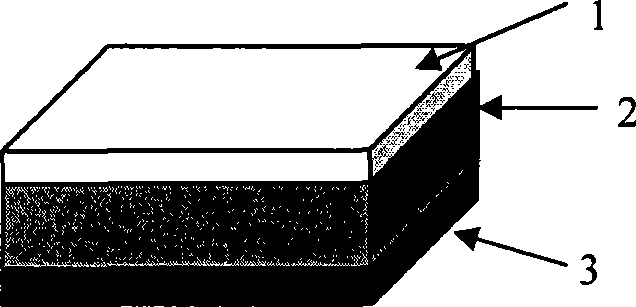

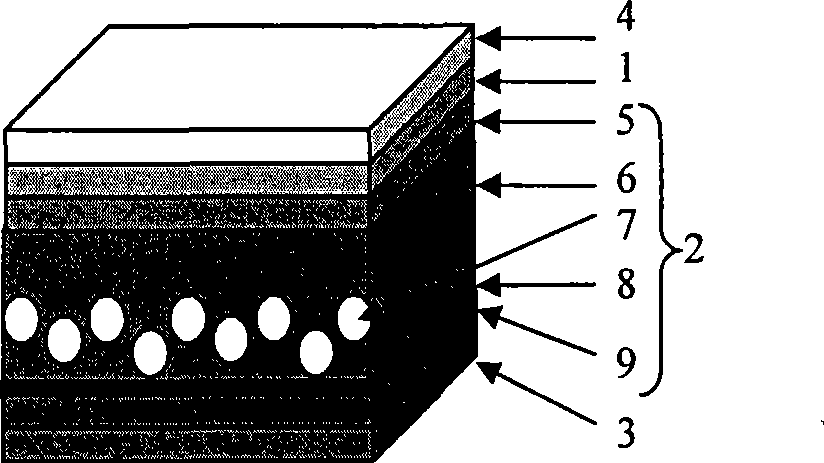

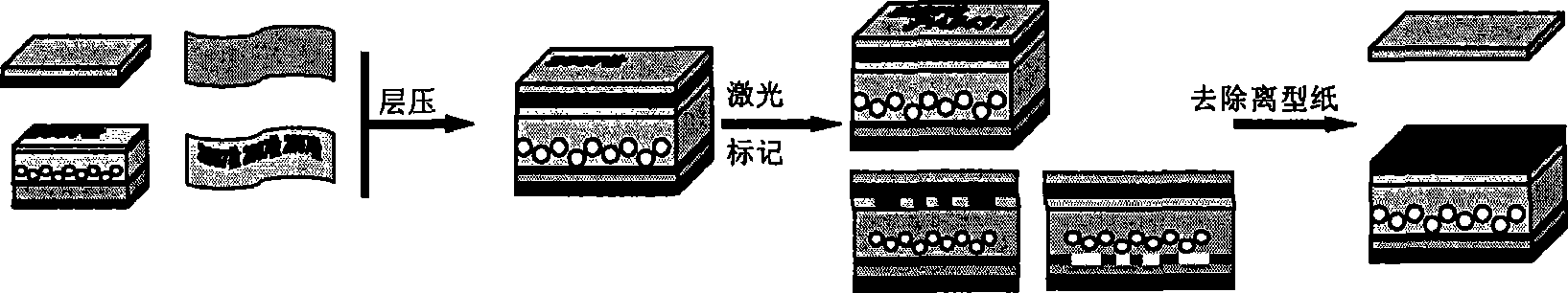

[0077] The product structure from top to bottom is: acrylic pressure-sensitive adhesive with a thickness of about 50 microns, polyvinyl butyral resin with a thickness of about 100 microns, glass microspheres with a diameter of about 50-80 microns, and aluminum with a thickness of 300-800 angstroms. Reflective layer, acrylic pressure-sensitive adhesive with a thickness of about 50 microns, black backing paper 100 microns. The top-down structure includes figure 2 Adhesive layer 1 , second adhesive layer 6 , transparent glass microsphere layer 7 , metal reflective layer 8 , first adhesive layer 9 and backing 3 shown in .

[0078]The copper phthalocyanine pigment is used as an additive and added to a solution of polyvinyl butyral containing other additives and modifiers, the proportion of which is about 1% to 2%. Two adhesive layers 6 ( figure 2 ), the overall appearance is light blue.

[0079] On this structure, an electro-optical Q-switched Nd:YAG laser with a wavelength of...

Embodiment 2

[0081] Using the formula in the patent JP2006256308, the additive is aluminum phthalocyanine pigment with an average particle size of 7.1 microns, which is added to the rubber-reinforced acrylic graft copolymer, acrylic copolymer, styrene copolymer and carbon black at a specific gravity of 0.1%. In the resin material composed of black material, the thickness is 260 microns, and both surfaces are covered with 20 micron PET resin.

[0082] The overall light transmittance of this structure is about 91%. The laser is "PowerLine-E" (1064nm) of Rofin-Bassel, the output is 24.0-30.0A, the frequency is 4.0-13.0kHz, and the scanning speed is 400mm / s. Green marking can be achieved with a 1064nm laser, and white marking can be achieved with a 532nm wavelength laser. If the middle layer of this structure is used to replace the vinyl resin in Example 1 (the thickness can be reduced according to the desired effect), namely figure 2 The protective layer 5 in the embodiment 1 can be used a...

Embodiment 3

[0085] Using the formula in the patent JP2006256308, similar to the above example, using quinacridone (di) ketone as an additive, the addition ratio is 0.2%, the processing technology and the parameters used for marking are the same as those in Example 2, and a 1064nm laser can be used to achieve purple marking. The structure can also be fitted on figure 2 The top or bottom of the middle protective layer 5 constitutes a part of the label, so as to realize the marking effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com